Suspension bushings are essential components in vehicles. They cushion the suspension system, reduce vibrations, and improve overall handling. Among the many material options available, the most frequently compared choices remain natural or synthetic rubber bushings and polyurethane (also called urethane) bushings. Each has its own set of advantages and disadvantages, making it important to understand the differences before deciding which one is best suited for your needs.

What Are Suspension Bushings?

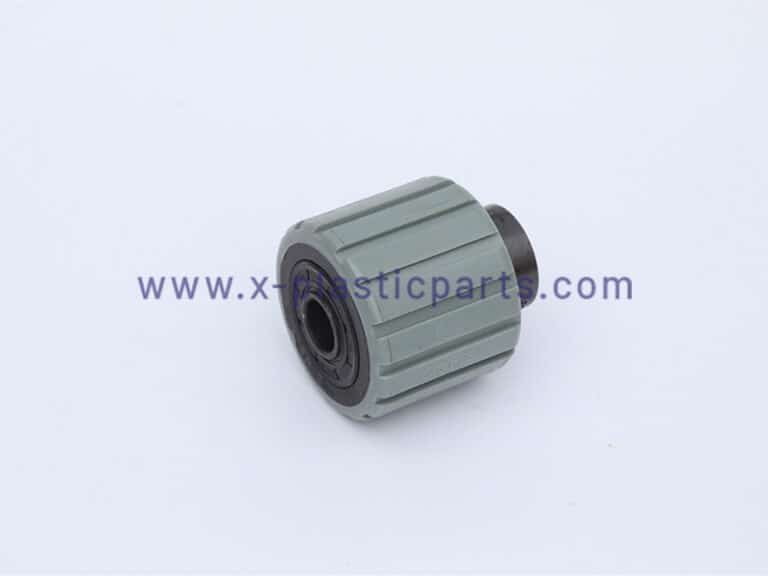

Suspension bushings are elastomeric components installed in control arms, sway bars, shock mounts, trailing arms, and other linkage points. Their primary functions are to allow controlled movement between metal parts, absorb road shock, reduce transmitted noise and vibration (NVH), and limit unwanted lateral movement. Without effective bushings, metal-on-metal contact would accelerate wear, increase cabin noise, and compromise steering precision.

Key Differences Between Rubber vs Urethane Bushings

When it comes to choosing the right material for suspension bushings, it’s important to consider the unique properties of rubber and urethane. Both materials serve similar functions but offer distinct performance characteristics.

| Property | Rubber Bushings | Urethane / Polyurethane Bushings |

|---|---|---|

| Flexibility | More flexible, ideal for comfort | Stiffer, provides better control and handling |

| Vibration & Noise Isolation | Very good, superior NVH reduction | Moderate, more road feel and noise transfer |

| Chemical & Ozone Resistance | Low, degrades from oil, fuel, UV, salt | Excellent, highly resistant to contaminants |

| Temperature Range | -40°C to ~90°C typical | -50°C to ~120°C typical |

| Deflection Under Load | Higher (more body roll) | Lower (reduced body roll, sharper response) |

| Maintenance | None, usually bonded, no lubrication needed | May require periodic greasing on some designs |

| Cost | Generally more affordable | More expensive upfront but lasts longer |

| Longevity | Shorter lifespan, needs replacement sooner | Longer lifespan, fewer replacements needed |

| Longevity | Shorter lifespan, needs replacement sooner | Longer lifespan, fewer replacements needed |

How to Choose the Right Suspension Bushing Material?

Flexibility and Vibration Damping

Rubber bushings provide greater compliance, which translates directly into better isolation of high-frequency road noise and harshness. This is why most factory vehicles use rubber or rubber-bonded bushings. Polyurethane bushings vs. rubber show the opposite behavior: higher stiffness reduces bushing deflection, resulting in more direct steering feel and less isolation from impacts.

Rigidity and Wear Resistance

Urethane bushings vs rubber clearly favor polyurethane in durability tests. Polyurethane has significantly higher tensile strength and tear resistance, so it maintains its geometry longer under repeated loading. In off-road, towing, or track applications where bushings undergo extreme deflection cycles, rubber bushings vs. polyurethane typically show rubber cracking, permanent compression, or separation from metal sleeves within a few seasons, while urethane versions remain intact.

Chemical Resistance and Long-Term Aging

Exposure to engine oil, transmission fluid, brake cleaner, road salt, and ozone causes standard rubber compounds to swell, soften, or harden prematurely. Polyurethane bushings vs rubber bushings demonstrate almost no degradation from the same contaminants.

Choosing PU vs Rubber Bushings by Application

- Daily Driving / Comfort: Rubber bushings give a softer ride and reduce noise and vibrations in control arms, sway bars, and engine mounts.

- Performance / Track Cars: PU bushings are stiffer, improving handling, steering precision, and reducing body roll.

- Off-Road / Heavy Loads: PU bushings withstand high loads and extreme suspension movements without tearing—ideal for trucks, SUVs, and towing.

- Chemical-Exposed / Outdoor Use: PU resists oils, fuels, road salts, and UV—perfect for exposed linkages or outdoor machinery.

- Sensitive Equipment / Vibration Isolation: Rubber bushings excel at damping vibrations and reducing noise for pumps, HVAC, or engine accessories.

Flexiparts: Custom Rubber & PU Bushings for Your Needs

Flexiparts leverages years of experience and advanced molding and machining processes to deliver fully customizable rubber and polyurethane bushings. We handle any production volume, from small prototypes to large OEM runs, allowing customers to select materials and hardness and rubber bushing type, customize sizes and geometries, and benefit from expert design for manufacturability support for high-performance, reliable bushings.

Conclusion

Material properties affect not only automobiles but also industrial equipment, mechanical connectors, and vibration-isolation components. For custom projects, there is no single best material. The right choice depends on your load, operating environment, and lifespan requirements. Flexiparts manufactures any size and geometry options and helps you select the material that best meets your application.