Custom plastic casing, plastic shell, plastic housing, plastic enclosure molding manufacturer

We specialize in custom plastic enclosures, offering you the flexibility to design a plastic enclosure that reppresents your company brand, including requirements such as styling, size parameters, color preferences, material choices, and IP rating specifications. As a specialized manufacturer of custom enclosures, we have the ability to take care of the entire production process, from mold design and production to plastic enclosures.

Our Advantages

1. We can customize unique products to customers’ requirements.

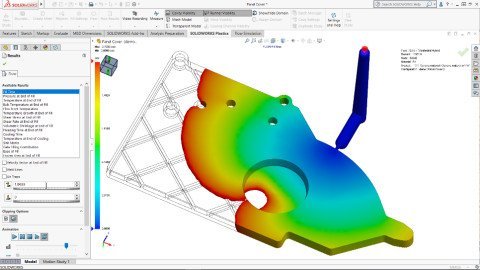

2. We can manufacture precision injection molds with low-cost.

3. We own sophisticated engineers, technologists, operators, and experts with rich work experience.

4. We have passed ISO9001 and have a strict quality control flow.

5. We have rich experience in working with various industries.

Common Materials of Plastic Enclosure

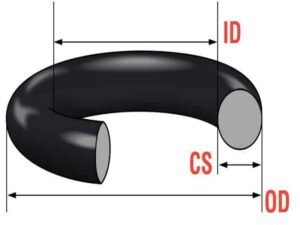

Every custom plastic enclosure application is unique. When selecting the plastic for your plastic enclosure, it is important to evaluate whether the plastic’s quality aligns with your specific usage requirements, ensuring that it keeps your electronics safe in normal environments. Using a variety of types, colors, and grades of materials, we can meet your custom plastic enclosure needs.

- Common materials for plastic housings and enclosures are:

- ABS: Glossy, UL 94HB, UL 94V0

- PA: Wear-resistant, great electrical insulator

- PC: Transparent, UV-resistant, high-strength

- PC+ABS: UL 94 V-0, high impact strength

- PMMA: Transparent, light-weight, high-light transmission

- HIPS (High impact polystyrene): UL 94HB, UL 94V0, high impact strength

Work with Erye to Make Custom Plastic Housing

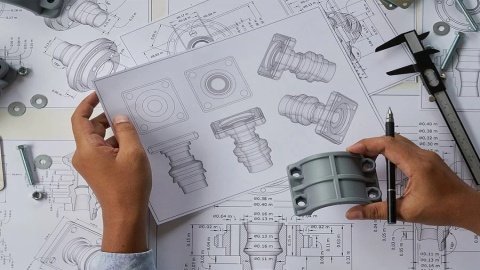

1. Design drawings according to product functions;

2. Send us the required drawing and get a quote;

3. Open a new mold;

4. Make a prototype and sample testing;

5. Mass production and quality control.