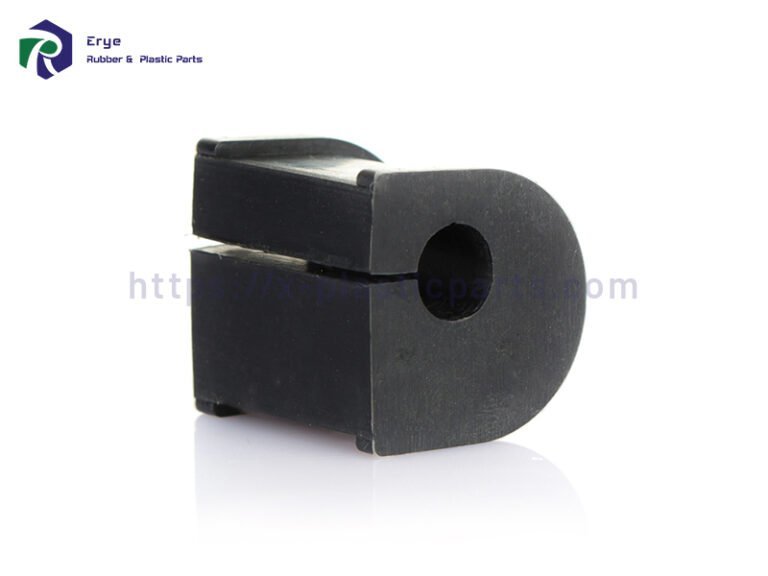

Custom Rubber Bushings

Custom Molded Rubber Bushings

Flexiparts Plastic is a leading manufacturer of custom rubber bushings, offering tailored solutions to meet your mechanical and environmental requirements. From mold design to production, we specialize in a wide range of rubber bushings that are engineered to reduce noise, absorb vibration, and extend the service life of your equipment.We make sure every rubber bushing is made with stable quality, fair pricing, and delivered on time.

Getting a custom rubber bushings solution is easy — send us your drawing or sample, and we’ll take care of mold design, quoting, and manufacturing. Reach out anytime via our website, email, or phone to get started.

Custom Rubber Bushings That Meet Your Exact Specifications

LET’S START A NEW CUSTOM RUBBER PARTS

Design Rubber Bushing Suggestion

When designing rubber bushings, focus on balancing flexibility, load support, and vibration control. Choose the right rubber hardness (durometer) based on static or dynamic loads. Keep the geometry practical—inner/outer diameter, flange, and wall thickness should match installation needs. Use materials that resist oil, heat, and fatigue. Also, consider compression and shear forces, working temperature, and how the part will be mounted to ensure long-term performance.

Rubber Bushing Molding Processes

- Compression Molding

- Injection Molding

- Insert Molding

- Transfer Molding

Material

We manufacture custom rubber bushings using high-performance materials, including:

- Natural Rubber (NR)

- Neoprene (CR)

- Nitrile (NBR)

- Ethylene Propylene Diene Monomer(EPDM)

- Silicone (MVQ)

- Polyurethane (PU)

- Fluorocarbon (FKM/Viton)

Benefit

Our rubber bush manufacturer team ensures each product delivers key operational benefits:

- Effective shock and vibration absorption

- Isolation of noise and mechanical stress

- Increased lifespan of moving components

- Enhanced ride comfort in automotive systems

- Reduced mechanical wear

- Corrosion and impact resistance

- Maintenance-free operation in harsh environments

Application

Flexiparts Plastic’s rubber bushings are trusted across a wide array of industries:

- Automotive: rubber suspension bushings, control arm bushings, torque rod mounts

- Industrial equipment: rubber mounting bushes for motors and compressors

- Railway and heavy-duty machinery: anti-vibration and load control

- HVAC and piping systems: noise isolation and seal protection

- Construction equipment: rugged, bonded bushings for extreme conditions

- Electrical enclosures: environmental sealing and component protection

Related FAQs of Rubber Bushing

Yes, as custom rubber bushing manufacturers, we design and mold rubber flange bushings to your exact dimensions and performance needs.

Nitrile (NBR) and neoprene bushings offer excellent resistance to oils, greases, and fuels.

Absolutely. Whether you need a few prototypes or thousands of parts, we are flexible with batch sizes.

Just contact us with your drawing, sample, or specifications. Our team will quickly provide a mold and production quote.

A standard rubber bushing is typically free-floating, while a bonded rubber bush features a metal core chemically or mechanically bonded to the rubber for higher structural strength.

What Our Customers Say