Custom Plastic Roller

Product Categories

Custom Plastic Parts

Custom Rubber Parts

Custom PU Parts

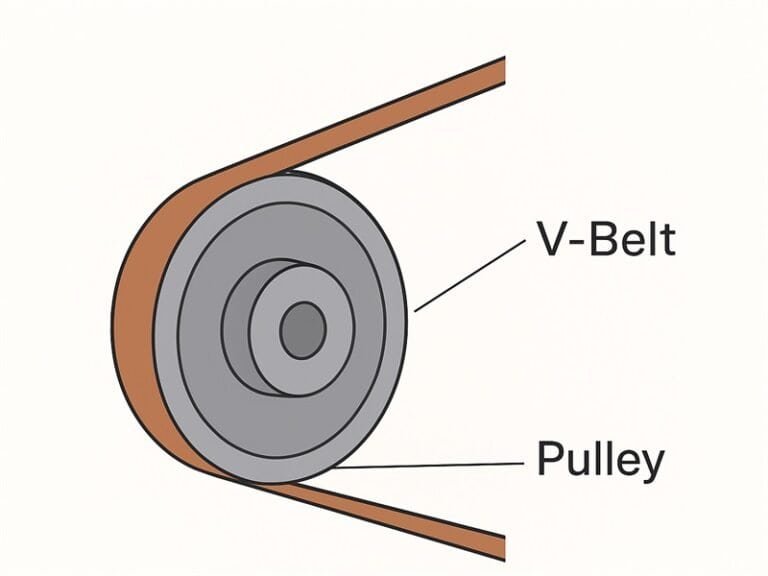

Custom Molded Plastic Roller

Flexiparts Plastic manufactures custom plastic rollers for conveyor systems, material handling, automation, and other equipment requiring quiet, low-friction operation. From mold making to full-scale production, our custom rollers are lightweight, durable, corrosion-resistant, and precisely molded or CNC-machined to meet your exact tolerances and surface finish requirements.

Getting a custom plastic roller solution is easy — send us your drawing or sample, and we’ll take care of mold design, quoting, and manufacturing. Reach out anytime via our website, email, or phone to get started.

Custom Plastic Roller to Fit Your Application

Design Plastic Roller Suggestion

When designing a custom plastic roller, focus on load capacity, friction, and wear resistance. Choose the right material and hardness to protect your belt or product. Ensure accurate bore size and tolerances for the shaft or bearing. Select profiles such as crowned, flanged, or textured surfaces based on tracking and traction needs. Define core structure, bearing type, and assembly method to achieve stable rotation and low vibration.

Manufacturing Process

- Injection Molding

- Overmolding

- Insert Molding

- CNC Machining

Available Material

- Polyamide (Nylon PA6, Nylon PA66)

- Polyoxymethylene (POM / Delrin)

- Ultra-High-Molecular-Weight Polyethylene (UHMW-PE)

- Polypropylene (PP)

- Polycarbonate (PC)

- Polytetrafluoroethylene (PTFE / Teflon)

- High-Density Polyethylene (HDPE)

- Thermoplastic Elastomer (TPE)

Benefits of Custom Plastic Rollers

- Smooth, quiet operation with low rolling resistance

- Excellent wear and corrosion resistance for long service life

- Lightweight construction reduces inertia and motor load

- Low maintenance and cost-effective replacement

- Non-marking and non-conductive options available

- Customizable surface textures, profiles and hardnesses

- Compatible with bearings, metal inserts, and shafts

Applications of Plastic Rollers

Flexiparts Plastic supplies custom rollers across industries, supporting reliable movement and handling in various systems.

- Conveyor systems and material handling

- Packaging and sorting equipment

- Automated assembly lines and robotics

- Printing and paper handling machinery

- Food processing lines (with food-grade materials)

- Textile and fabric handling systems

- Medical and laboratory devices

- Office equipment and vending machines

FAQs of Plastic Molded Rollers

What Our Customers Say