Suspension bushing is a key component used to isolate vibration, reduce noise, and protect metal parts in many types of equipment. It is widely used in automotive suspension systems as well as in industrial machinery, construction equipment, agricultural machines, and other applications. Flexiparts is an on-demand manufacturer that offers customized materials and dimensions to match different working conditions and performance requirements.

What Is a Suspension Bushing?

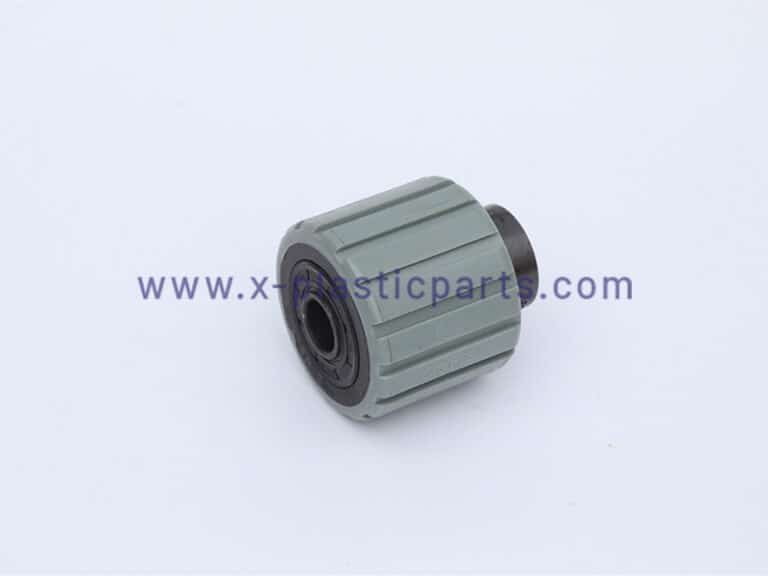

A suspension bushing is an elastic element installed between two components, usually at connection or pivot points, to absorb vibration, reduce noise, and allow controlled movement. It is commonly made from materials such as rubber, polyurethane, or other engineered elastomers, often combined with metal sleeves or inserts for strength and precise mounting. Suspension bushings can be used in vehicle suspensions, industrial equipment mounts, machinery joints, and any application that needs both flexibility and support.

The Importance of Suspension Bushings

In automobiles, suspension bushings contribute to overall vehicle performance and safety. They connect metal components in the suspension system, allowing controlled movement while reducing direct contact. This setup helps manage forces from road surfaces, such as bumps or turns. For instance, in a car’s front suspension, bushings in the control arms absorb impacts, which support wheel alignment and tire contact with the road.

Suspension bushing also contributes to ride comfort by isolating road vibrations and reducing noise transmitted into the cabin. A worn or damaged suspension bushing can lead to clunking noises, vibration in the steering wheel, unstable braking, and uneven tire wear. In severe cases, it can affect vehicle safety and accelerate wear of other suspension components, increasing overall maintenance costs.

Types of Suspension Bushings

Suspension bushings come in various types, differentiated by the materials used in their construction. Each material offers specific stiffness, durability, and comfort suited to different requirements.

Rubber Suspension Bushing

Rubber suspension bushings are the most common type. Made from natural or synthetic rubber, they provide good flexibility and vibration absorption. These bushings are cost-effective and perform well in standard driving conditions. However, standard rubber can wear faster under heavy loads, extreme temperatures, or exposure to oils and chemicals.

Polyurethane Suspension Bushing

Polyurethane suspension bushings offer greater durability compared to rubber. They resist wear and maintain shape under stress, making them suitable for performance-oriented vehicles, heavy-duty vehicles, and industrial equipment. Polyurethane provides a firmer feel, which can improve handling precision. These bushings are less prone to cracking and can handle higher temperatures.

Silicone-Based Suspension Bushings

Silicone-based suspension bushings are used in applications requiring resistance to extreme conditions. Silicone maintains elasticity in cold or hot environments and resists chemicals. This makes them appropriate for specialized uses where other materials might fail.

Composite Suspension Bushings

Composite suspension bushings combine materials like rubber with fibers, graphite-filled polymers, nylon, or metals for enhanced strength. They aim to balance comfort with longevity, often used in heavy-duty vehicles.

Applications of Suspension Bushings Across Industries

Suspension bushings extend beyond automobiles to various industries where vibration control and component connection are essential.

Automotive

Suspension bushing is installed in control arms, trailing arms, stabiliser bars, subframe mounts, engine mounts, and other chassis locations. It helps maintain wheel alignment, improves steering stability, and protects the vehicle body and frame from shock loads.

Construction and Heavy Equipment

In excavators, loaders, cranes, and other heavy machines, suspension bushing is used in boom pivots, chassis supports, and operator cabins. It supports high loads and frequent movement while helping reduce vibration transmitted to the operator and machine structure.

Industrial Machinery

Compressors, pumps, fans, generators, and machine tools often use suspension bushings or similar elastomer mounts at base plates and connection points. This reduces vibration and noise, protects foundations, and helps equipment run more consistently.

Agricultural

Suspension bushing is also used in tractors, harvesters, and other agricultural machines to handle uneven terrain and continuous operation.

Rail Applications

In rail vehicles, similar components are used between bogies, frames, and bodies to manage vibration, noise, and structural loads.

When to Consider Custom Suspension Bushings

Custom suspension bushings become necessary in situations where standard options do not meet specific requirements. Custom suspension bushing helps match the exact mechanical, environmental, and dimensional needs of the application.

Non-standard dimensions or mounting geometry

Existing equipment may have unique housing sizes, shaft diameters, or limited installation space. Custom suspension bushing ensures proper fit and function when standard dimensions do not match.

Special operating conditions

When equipment operates under extreme high or low temperatures, continuous heavy loads, strong vibration, or frequent shock impacts, standard materials may not maintain performance over time. Custom suspension bushings with tailored materials and hardness can improve durability and stability.

Exposure to specific media

Applications in contact with oil, fuel, chemicals, water, or abrasive dust can degrade general-purpose materials. Custom suspension bushings can be formulated to resist these media, extending service life and reducing unexpected failures.

Lifecycle and maintenance goals

For equipment where shutdown is costly, users may want a suspension bushing designed for longer inspection intervals and reduced maintenance. Customized designs can improve durability and make replacement easier, supporting overall cost control.

Flexiparts for Custom Suspension Bushing

Flexiparts provides custom suspension bushing manufacturing services tailored to specific customer needs, including material selection, design optimization, and production using processes such as injection molding, compression molding, CNC machining, and custom mold development. We supports projects from prototyping, testing, and mass production to ensure reliable performance in diverse applications. Contact us to get a custom solution for your suspension bushing project.

Related FAQs of suspension bushings

Replace suspension bushings when you notice clunking noises, excessive vibration, steering wheel shake, uneven tire wear, or loose handling during braking or cornering.

Rubber bushings suit daily drivers for better comfort and quiet operation, but wear faster under heavy loads. Polyurethane (PU) bushings offer longer life, stiffer response, and better durability for performance or heavy-duty use, though they may increase noise and need lubrication. Learn more about rubber vs pu bushing.

Suspension bushings are elastomeric components that absorb vibration, reduce noise, and allow flex at pivot points. Bearings support rotation with low friction using rolling elements or sleeves, focusing on smooth motion rather than vibration isolation.

Provide drawings or 3D models, dimensions, material preferences, load/force requirements, operating temperature, environmental exposure (oils, chemicals), and expected lifespan or performance targets. Samples or working condition details help refine the design.