Idler pulley is an important component in mechanical systems and power transmission. It has an impact on the efficiency, reliability, and longevity of belt-driven machinery. This article unpacks what an idler pulley is, explores the different types of pulley idler mechanisms, details their applications, weighs their advantages and disadvantages.

What Is Idler Pulley?

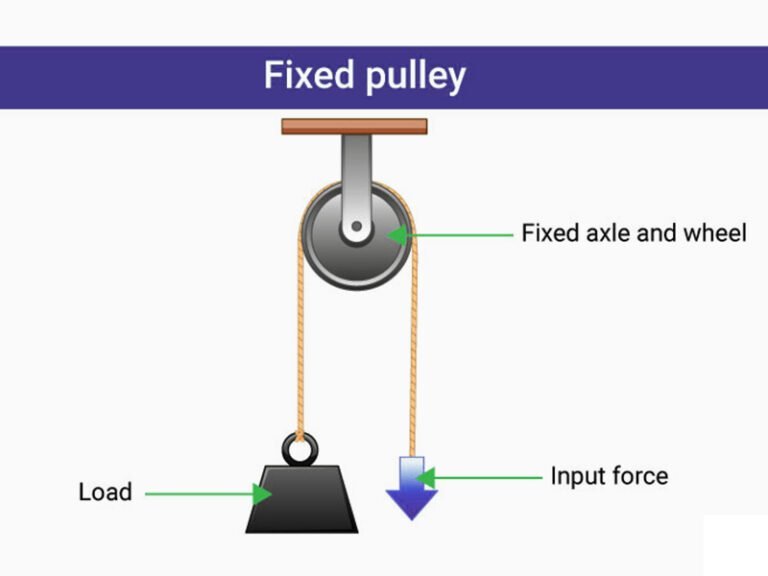

An idler pulley is a wheel that supports or guides a belt or chain in a mechanical system without transmitting power directly. Unlike drive pulleys, which deliver motion, pulley idler wheels serve to maintain proper tension, different from tensioners, which redirect the belt or take up slack to ensure smooth operation. Typically mounted on a fixed or adjustable bracket, idler pulleys help optimize belt path geometry and reduce wear on the drive components.

The idler pulley consists of several parts, including the pulley wheel itself, a bearing assembly to facilitate smooth rotation, a shaft or mounting mechanism, and often a housing or bracket. Together, these components enable the idler pulley to perform its role with minimal friction and maximal durability.

Types of Idler Pulleys and Their Applications

Idler pulleys come in several types suited to different functional requirements and mechanical configurations.

Flat/Smooth Idler Pulleys

Flat or smooth idler pulleys feature a flat surface, sometimes with a slight crown to help center the belt. They are made from materials like steel or plastic and are used in household appliances such as dryers or in light conveyor systems. These pulley idler types are suitable for low-load operations with flat belts, where simple guidance is needed.

V-Groove Idler Pulleys

V-groove idler pulleys have a trapezoidal groove with support ribs to hold V-belts securely. Constructed from reinforced nylon or steel, they are common in automotive engines for serpentine belt systems and in industrial machinery. These idler pulleys provide high grip to prevent belt offset in high-tension environments.

Timing Idler Pulleys

Timing idler pulleys use a toothed surface to engage with synchronous belts, ensuring precise timing. Made from composites or steel, they are applied in agricultural tractors and power tools. This pulley idler type supports applications requiring synchronized motion, such as in harvesters or drills.

Heavy-Duty Idler Pulleys

Heavy-duty idler pulleys incorporate sealed bearings to handle high loads and are typically made of solid steel. They are used in construction equipment like excavators and hoists, where extreme tension and heat are present, ensuring durability in demanding conditions.

Plastic Idler Pulleys

Plastic idler pulleys, often made from nylon 6/6 with glass fiber, are lightweight and corrosion-resistant. They are used in lawn mowers and outdoor gear, ideal for moisture-prone, low-duty tasks where weight reduction is a priority.

Advantages and Disadvantages of Idler Pulleys

Advantages of Idler Pulleys

- Improved Belt Performance: By ensuring correct tension and alignment, idler pulleys reduce belt slippage and prolong belt life.

- Noise and Vibration Reduction: Smooth operation leads to less system noise and reduced vibration.

- System Longevity: Reduces wear on drive components and allows for better load distribution.

- Versatility: Suitable for numerous applications across different industries.

Disadvantages of Idler Pulleys

- Wear and Tear: Bearings and pulley surfaces are subject to wear, requiring periodic inspection or replacement.

- Additional Complexity: Installation of idler pulleys introduces extra components that can fail.

- Maintenance Needs: Spring-loaded and adjustable types may need more frequent checking to maintain proper tension.

Customization Process for Idler Pulleys

Customizing an idler pulley involves a carefully coordinated process to meet specific operational demands and environmental factors:

- Requirement Analysis: Identify the belt size, type, load, speed, mounting style and operational environment.

- Material Selection: Choosing metals like steel or aluminum, or engineering plastics, based on strength, corrosion resistance, and weight considerations.

- Design Specification: Use software to define dimensions, such as diameter and groove shape. Include features like crowns for belt centering.

- Manufacturing Method: For high-volume production, stamping is applied to form steel halves around bearings. Injection molding is used for plastic idler pulleys to create complex shapes.

- Assembly: Integrate idler pulley bearings into the wheel. Add brackets or springs if needed for tensioning.

- Testing: Check for alignment, rotation smoothness, and load capacity. Tests ensure compliance with standards like CEMA for conveyor applications.

- Quality Control: Inspect for defects and verify dimensions. This step confirms the pulley idler meets performance criteria.

Key Factors in Customizing the Right Idler Pulley

When tailoring an idler pulley for specialized applications, attention must be given to:

Load Capacity and Speed: Ensuring the pulley can accommodate expected forces and rotational speeds.

Environmental Conditions: Resistance to chemicals, moisture, heat, or dust must be factored into material and bearing choices.

Dimensional Accuracy: Precise dimensions maintain belt alignment and system function.

Compatibility: The pulley should fit seamlessly within the existing mechanical assembly.

Maintenance Accessibility: Design considerations that facilitate inspection and replacement.

Conclusion

Idler pulleys serve as supportive elements in belt systems, with different types. They offer advantages like reduced wear but require attention to disadvantages such as load limits. Flexiparts provides services in customizing plastic idler pulleys, focusing on materials like reinforced plastics, ensuring compatibility with belts, maintaining quality standards, and matching specific applications from automotive to industrial uses. Contact Flexiparts for recommendations on pulley idler solutions.