In the automotive industry, rubber grommets are key components that contribute to vehicle performance and safety. These small yet essential parts are designed to support and protect various systems, ensuring cables, hoses, and other components pass through panels securely. By preventing wear and tear, reducing vibration, and providing insulation, automotive custom rubber grommets help maintain the integrity and longevity of a vehicle, especially in high-stress areas like the engine bay, suspension, and electrical systems.

What Are Automotive Rubber Grommets?

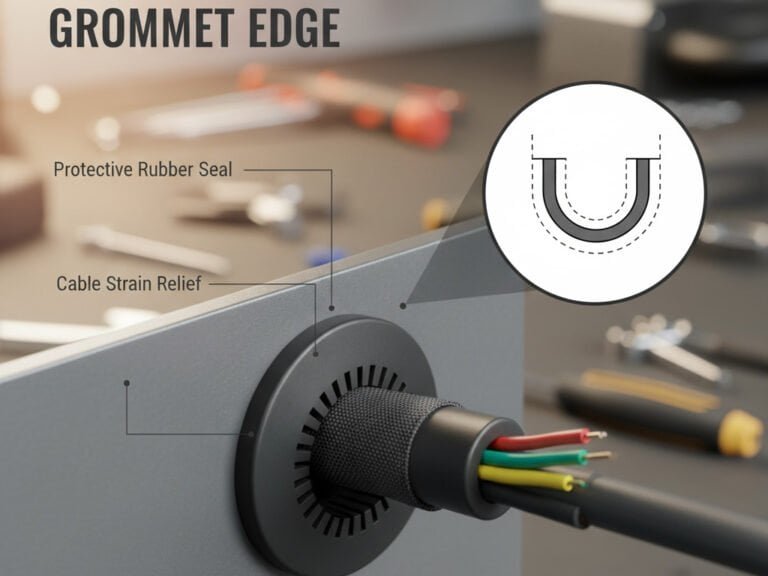

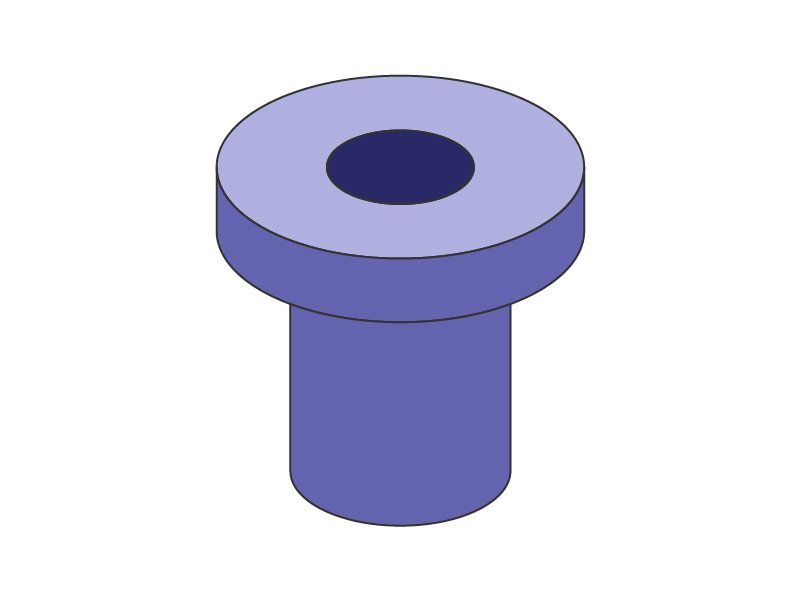

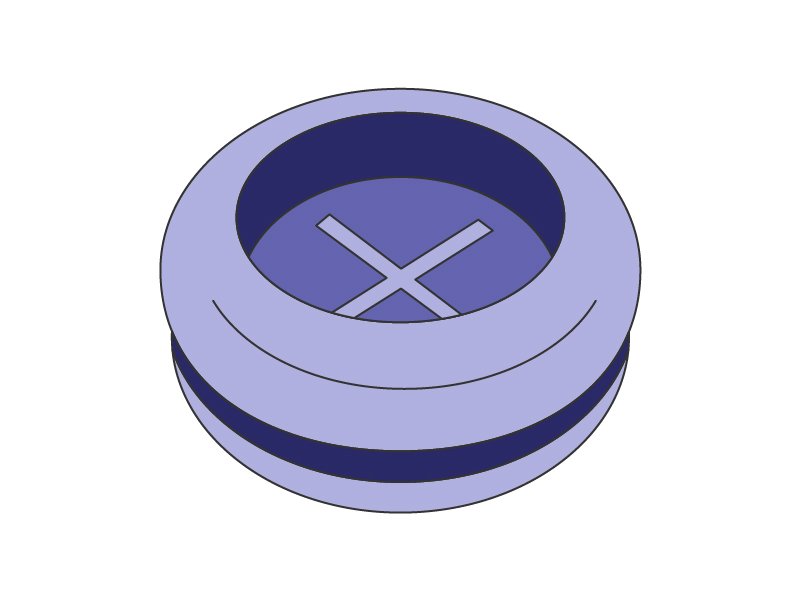

Automotive rubber grommets are small, circular rings made from flexible materials like rubber, silicone, or neoprene. They are designed to be inserted into holes in metal or plastic panels to protect wiring, cabling, and tubing from sharp edges, abrasion, vibration, heat, and environmental contaminants. Their flexibility allows them to adapt to different cable diameters and panel thicknesses, providing a tight seal. Common advantages include durability, flexibility, insulation, heat resistance, weather resistance, and easy installation, making them essential in automotive, electrical, construction, and industrial applications.

The Role of Automotive Rubber Grommets in Vehicles

Automotive rubber grommets for cars serve multiple functions within the vehicle assembly and operation process.Protection Against Mechanical Damage

Rubber grommets protect automotive wiring, fuel lines, brake lines, and hoses from abrasion and cutting as they pass through metal or rough surfaces, maintaining insulation and system integrity.Electrical Insulation and Safety

By preventing wires from contacting metal parts, rubber grommets reduce the risk of electrical shorts, ensuring safe and reliable operation of automotive electrical systems.Sealing and Environmental Protection

Rubber grommets create tight seals around cables, blocking moisture, dust, and contaminants from entering sensitive areas like the engine or cabin, enhancing component durability.Vibration Damping

Rubber grommets absorb vibrations and shocks, protecting delicate parts like sensors and wiring, while reducing cabin noise and extending component lifespan.Supporting Customization and Upgrades

Custom rubber grommets enable tailored solutions for unique builds, ensuring seamless integration of aftermarket components and professional cable management.Ease of Installation and Maintenance

Rubber grommets are easy to install and replace without special tools. Their flexibility simplifies inspections and adjustments, making them a cost-effective choice for vehicle upkeep.Enhancing Vehicle Longevity

By protecting key components from damage and wear, rubber grommets play a crucial role in extending the lifespan and reliability of a vehicle. By combining protection, sealing, and vibration damping, rubber grommets in automotive components contribute to a vehicle’s overall durability. They prevent premature wear on critical systems, reduce maintenance costs, and ensure consistent performance over time. From daily commuters to high-performance sports cars, auto wire grommets play a vital role in keeping vehicles on the road longer.Benefits of Rubber Grommets in Automotive Customization

In automotive customization, rubber grommets play a key role in achieving both functionality and aesthetics. Beyond standard protection, custom grommets allow precise fitment for unique builds, ensuring clean cable routing, seamless integration of aftermarket components, and professional-grade finishing. They also give designers greater flexibility in choosing shapes, sizes, and materials to match specific performance or styling needs. For enthusiasts and manufacturers alike, customized rubber grommets not only enhance reliability but also elevate the overall quality and craftsmanship of a vehicle.Common Types of Automotive Rubber Grommets

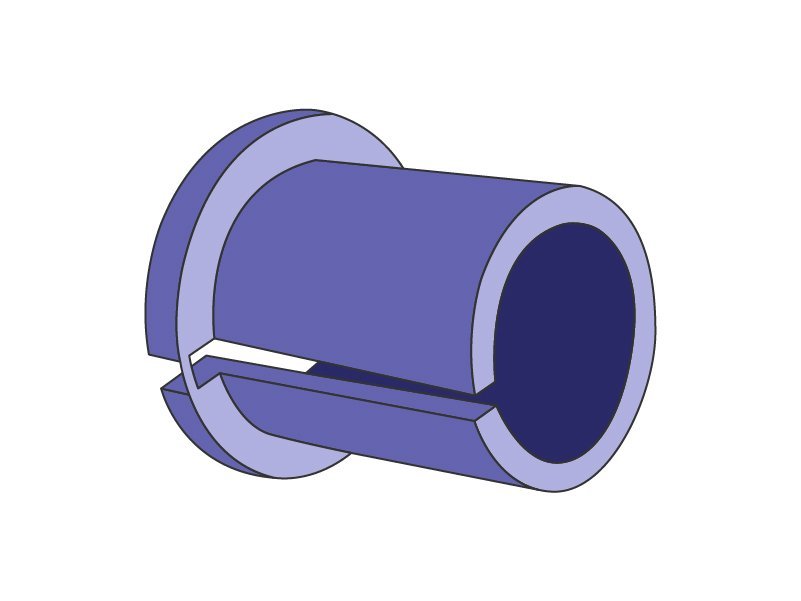

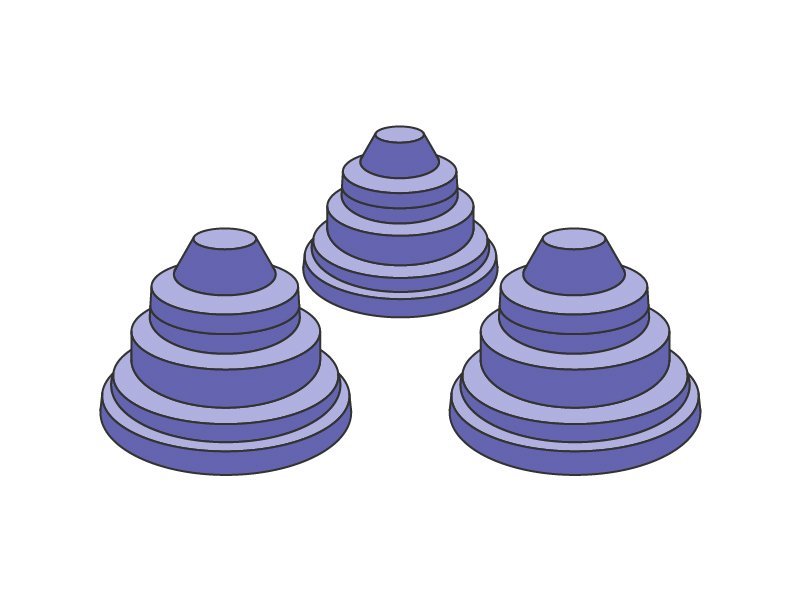

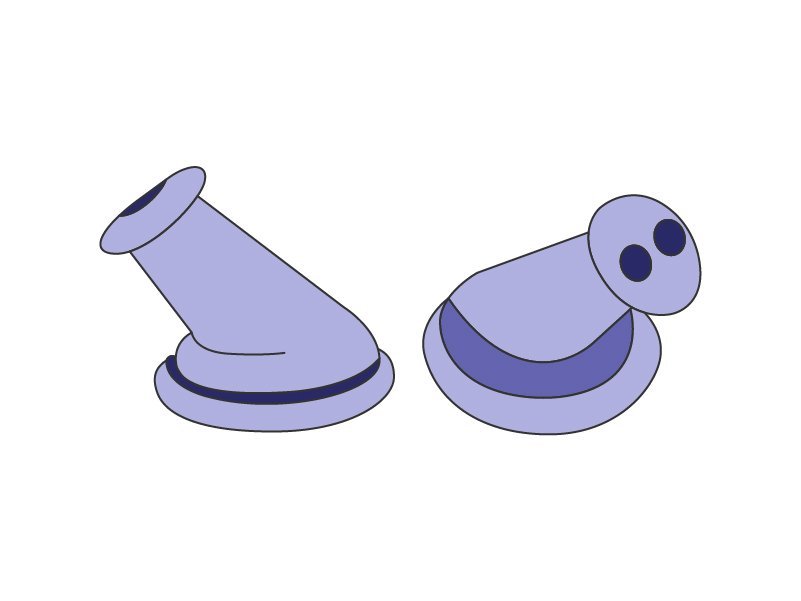

Automotive rubber grommets come in various specialized forms to suit a wide range of protective and sealing functions in vehicle wiring and component assemblies. Below is a detailed overview of common types used in automotive applications:

Flexiparts Automotive Grommet Manufacturer

When customizing automotive rubber grommets, it is important to consider the operating environment, material compatibility, dimensional accuracy, and mounting method to ensure long-term sealing, vibration isolation, and wire protection. Flexiparts specializes in manufacturing high-quality automotive rubber grommets with expert material selection, durability focus, and tailored designs that enhance vehicle safety and performance. Whether you need grooved, edge, sleeved, or strain relief grommets, welcome to contact Flexiparts for a reliable custom solution.