Custom Plastic Roller

Flexiparts custom-designed plastic roller are built for your application, providing smooth motion, quiet operation, and long-lasting performance.

Product Categories

Custom Plastic Parts

Custom Rubber Parts

Custom PU Parts

Washers & O-Rings, Polyurethane Gasket Manufacturing

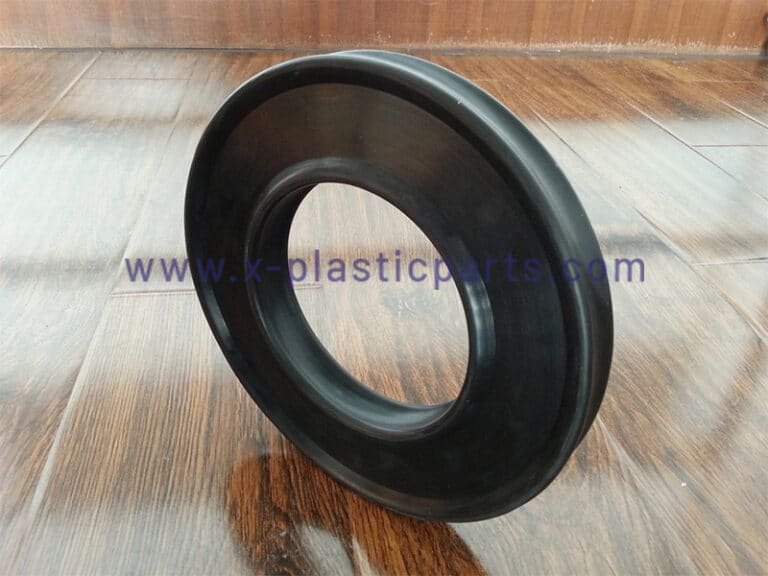

Urethane seal gaskets are a preferred choice for engineers looking for long-lasting materials in demanding applications. Polyurethane seal is known for its unique combination of properties that make it suitable for various industrial applications including:

- Automotive insulating components

- Electronics enclosure seals

- Medical devices seal

- Air conditioning systems seal

- PU gasket for engine compartments in aerospace

We specialize in producing custom PU seal gaskets tailored to your specific needs. Our custom design specs include: durometer hardness, shape and size, color, application specific formulas.

Custom PU Seals to Fit Your Requirements

Flexiparts offers fully customizable PU seals, including gaskets, washers, and O-rings, tailored to your specific design, dimensional, and performance requirements.

Design Considerations for Polyurethane Seals

When designing custom PU seals such as gaskets, washers, or O-rings, factors to consider include seal type and dimensions, hardness measured by Shore A rating, compression and elasticity requirements, operating pressure, chemical and temperature resistance, wear and abrasion conditions, environmental exposure including moisture, UV, and oils, dynamic or static application, surface finish, and compatibility with mating components or shafts to ensure reliable, leak-proof, and long-lasting performance.

PU Material Selection and Enhancement

PU naturally fits the demands of gaskets, washers, and O-rings, offering durability and resilience. Flexiparts further enhances performance through customized hardness, shape, and material properties for challenging applications.

PU Seals Casting Process

- Material Preparation: Mix PU for hardness, elasticity, chemical resistance.

- Mold Preparation: Clean mold and apply release agent.

- Mixing/Degassing: Blend components and remove air bubbles.

- Pouring: Fill mold for accurate, consistent seal shapes.

- Curing: Harden PU into durable, wear-resistant seals.

- Demolding: Remove seals carefully without deformation.

- Finishing: Trim flash and inspect for quality.

Applications of Polyurethane Seals

Flexiparts PU seals are used across a wide range of industries and applications, including:

- Industrial machinery and automation equipment

- Automotive engines, transmissions, and fluid systems

- Valves, pumps, and piping for fluid handling

- HVAC and ventilation systems

- Office machinery and printing equipment

- Medical and laboratory devices

- Any system requiring reliable sealing, vibration damping, or wear protection

FAQs about Custom PU Seals

Can I customize color, hardness, or other properties of PU seals?

Absolutely. Gaskets, washers, and O-rings can be tailored in hardness, color, and material for your specific operating conditions.

When should I use a PU O-ring?

PU O-rings are ideal for sealing round shafts, pipes, or dynamic parts, providing reliable performance under pressure, movement, and exposure to oils or chemicals.

What’s the difference between a PU gasket and a rubber gasket?

PU gaskets are durable, wear- and chemical-resistant, and maintain shape under pressure. Rubber gaskets are softer, more elastic, and conform better to uneven surfaces but wear faster.

How do PU washers compare to rubber washers?

PU washers resist deformation, handle load well, and offer moderate vibration damping. Rubber washers provide better cushioning and vibration absorption but compress more easily over time.

Can you produce a PU seal part from a sample or drawing?

Yes. A gasket, washer, or O-ring can be made from a physical sample or detailed drawing, ensuring proper fit and performance.

What Our Customers Say

Check what our customers say about us, why they like to work with us!

Flexiparts pays attention to detail. We’re happy with their plastic and rubber molds. Communication is fast and efficient, and their support is great.

Edward

France

Working with Flexiparts has been great. The injection-molded parts are always top quality. We really appreciate your professionalism with delivery and project management

Bella

US