Custom Plastic Strips & Profiles

Product Categories

Custom Plastic Parts

Custom Rubber Parts

Custom PU Parts

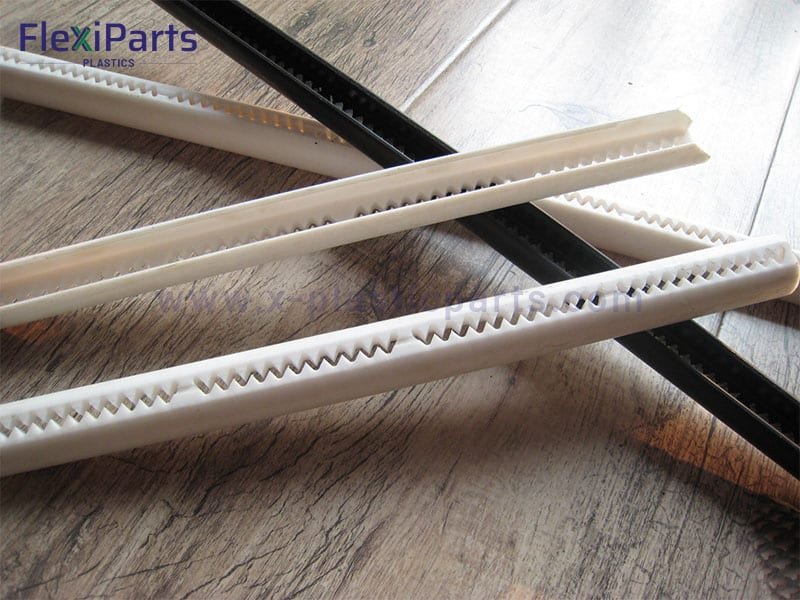

Precision Plastic Strips for Sealing, Edging, and Protection

Flexiparts Plastic specializes in custom plastic strips and profiles produced through precision extrusion. Custom solutions for sealing gaps, edge protection, structural support, insulation, cable management, and equipment finishing. We offer flexible, semi-rigid, and rigid profiles and strips manufactured according to your drawings, samples, or functional requirements, ensuring stable dimensions, excellent impact resistance, and consistent surface quality.

Getting a custom plastic strip or profile is easy. Simply send us your design or sample, and we will manage extrusion die development, quotations, trial runs, and full production. Contact us via our website, email, or phone to get started.

Custom Plastic Strips for Your Application

Design Plastic Strip Suggestion

When designing a plastic extrusion strip, consider its functional role, required flexibility, mechanical load, installation method, key dimensions, material selection, and surface finish. Also ensure the profile is suitable for extrusion and that environmental conditions, durability, and appearance requirements are addressed to maintain stable performance and consistent quality.

Manufacturing Process

- Extrusion

- CNC Machining

- Injection Molding

Available Material

- Polyvinyl Chloride (PVC)

- Polyethylene (PE)

- Polypropylene (PP)

- Thermoplastic Elastomer (TPE/TPU)

- Acrylonitrile Butadiene Styrene (ABS)

- Polycarbonate (PC)

- Nylon (PA6/PA66)

- Thermoplastic Rubber (TPR)

Benefits of Custom Plastic Strips

- Stable extrusion with uniform dimensions

- Strong resistance to impact, bending, and wear

- Available in flexible or rigid options

- Excellent UV, corrosion, and chemical resistance

- Supports co-extrusion and dual-material structures

- Wide color and surface customization

- Cost-effective for long continuous lengths

Applications of Plastic Strips

- Edge protectors for panels and sheets

- Furniture and cabinet trim

- Automotive interior and exterior strips

- Window and door sealing strips

- Cable routing and wire management

- Machine protective strips

- Decorative profiles and finishing trims

FAQs of Plastic Profile & Strip

We can custom-build extrusion dies based on your drawings or samples to produce profiles of almost any shape.

What Our Customers Say