Custom Plastic Molded Handle

Product Categories

Custom Plastic Parts

Custom Rubber Parts

Custom PU Parts

Custom Plastic Handle Manufacturer

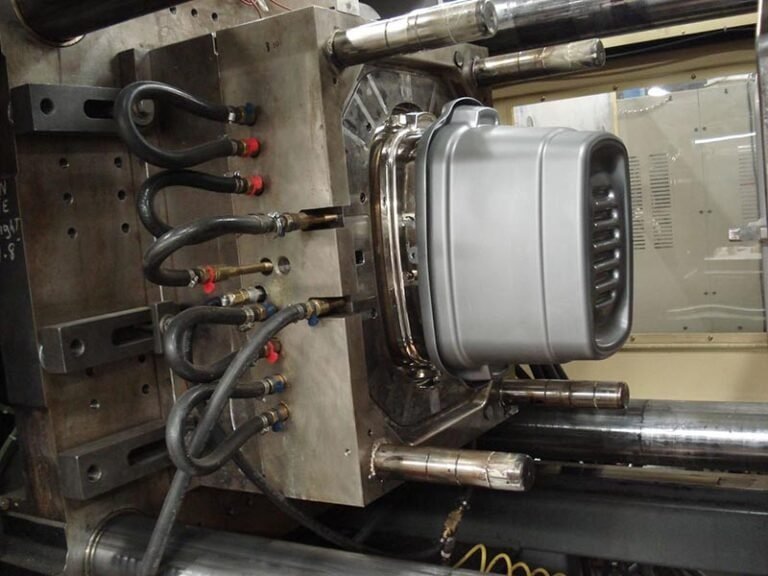

We specialize in custom plastic handle, offering you the flexibility to design a plastic handle that represents your company brand, including requirements such as styling, size parameters, color preferences, and material choices. As an experienced manufacturer, we manage the entire production process from mold making to finished handles so you get durable, precise, and ready-to-use products.

Getting a custom plastic handle solution is easy — simply send us your drawing or sample, and we’ll manage the mold design, quotation, and full production process. Reach out via our website, email, or phone to get started.

Plastic Handles Built for Your Applications

Plastic Handle Design Suggestion

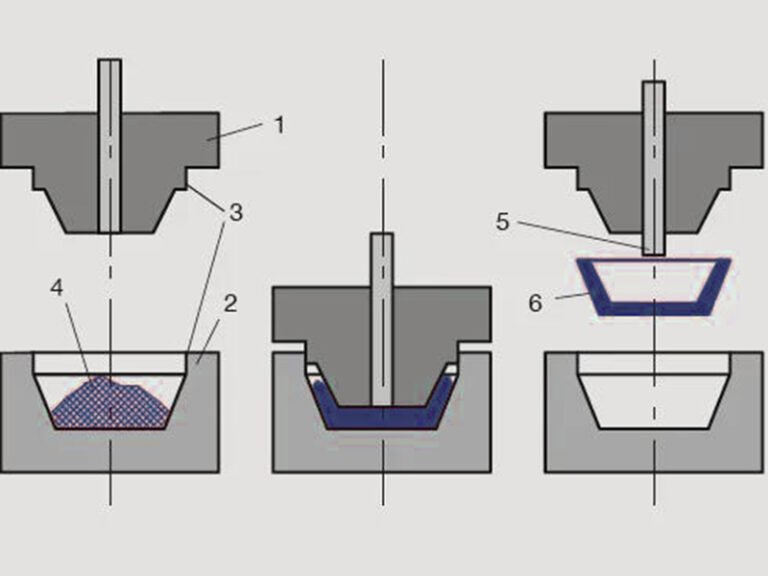

When designing a custom plastic handle, consider grip comfort, shape, load capacity, and durability. Choose materials based on forces, environment, and touch requirements. Define dimensions, surface texture, reinforcement, inserts, and assembly method to ensure reliable performance and a comfortable user experience.

Manufacturing Process

- Injection Molding

- Overmolding

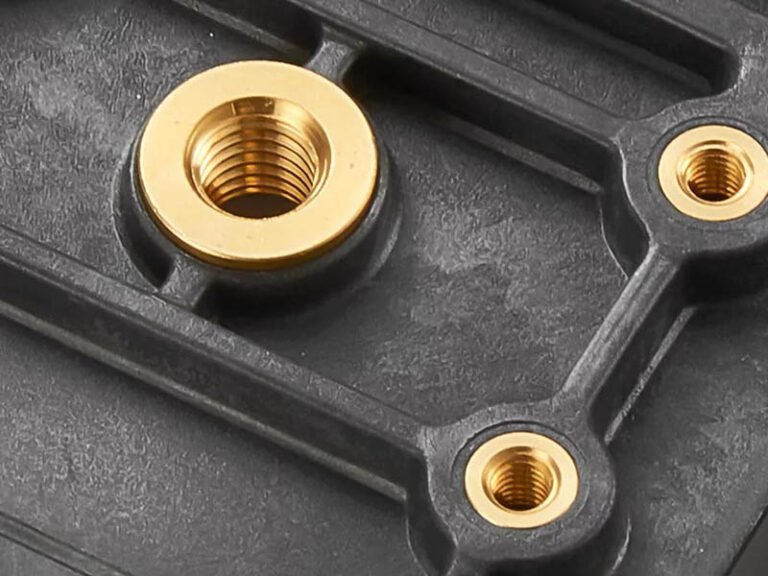

- Insert Molding

- CNC Machining

Available Material

- Acrylonitrile Butadiene Styrene (ABS)

- Polypropylene (PP)

- Polyamide (Nylon PA6/PA66)

- Polycarbonate (PC)

- Thermoplastic Elastomer (TPE/TPU)

- Glass-Fiber Reinforced Plastics

- Acetal (POM)

Benefits of Custom Plastic Rollers

- Lightweight but strong structure

- Ergonomic grip and comfortable touch

- High impact and wear resistance

- Excellent corrosion and chemical resistance

- Available with textures, soft-touch layers, or color customization

- Compatible with metal inserts and overmolding

- Cost-effective for both low and high-volume production

Applications of Plastic Rollers

- Power tools and hand tools

- Appliances and home devices

- Industrial and machinery handles

- Medical equipment and lab devices

- Furniture, cabinets, and drawer pulls

- Sports and outdoor equipment

- Automotive interior and control handles

FAQs of Plastic Handles Supplier

What Our Customers Say