Molded Plastic Grips Supplier

Ergonomic, durable plastic grips, produced to your exact specifications.

Product Categories

Custom Plastic Parts

Custom Rubber Parts

Custom PU Parts

Custom Injection Molded Plastic Grips

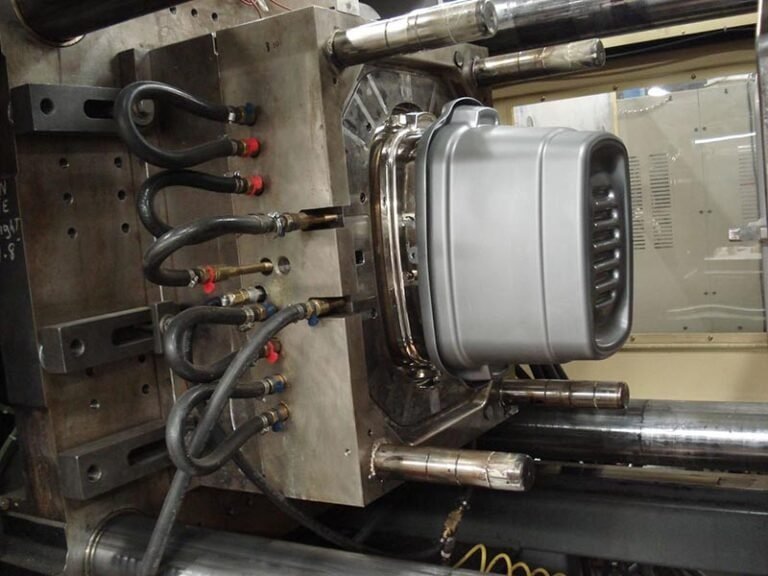

Flexiparts Plastic provides custom-molded plastic grips tailored for hand tools, machine handles, sports gear, equipment controls, and consumer products. Each grip delivers comfort, solid gripping force, and reliable durability under repeated use.

Custom grips built to your exact specifications, offering lightweight, high-strength, and corrosion-resistant performance through precision injection molding or CNC machining.

Getting a custom plastic handle grip is simple. Send us your drawing, 3D model, or sample, and we will handle mold development, tooling, quotation, and full-scale production. Contact us through our website, email, or phone to begin your project.

Custom Plastic Grips for Your Application

Plastic grips come in many shapes and functions depending on use and environment. Flexiparts provides custom production of grips to your specifications, including special patterns, anti-slip textures, complex geometry, and extended durability.Design Plastic Grip Suggestion

When designing a custom plastic grip, consider comfort, finger placement, load distribution, and friction properties. Define precise dimensions such as diameter, internal bore size, grip length, wall thickness, rib patterns, and end-cap style. Select materials based on usage frequency, environmental exposure, and required tactile response. Incorporate surface textures, soft zones, reinforcement ribs, or overmolding where necessary. Also evaluate assembly method, pushing or sliding force, sweat resistance, torque transfer, and fatigue performance to ensure a grip that feels natural and performs reliably.Manufacturing Process

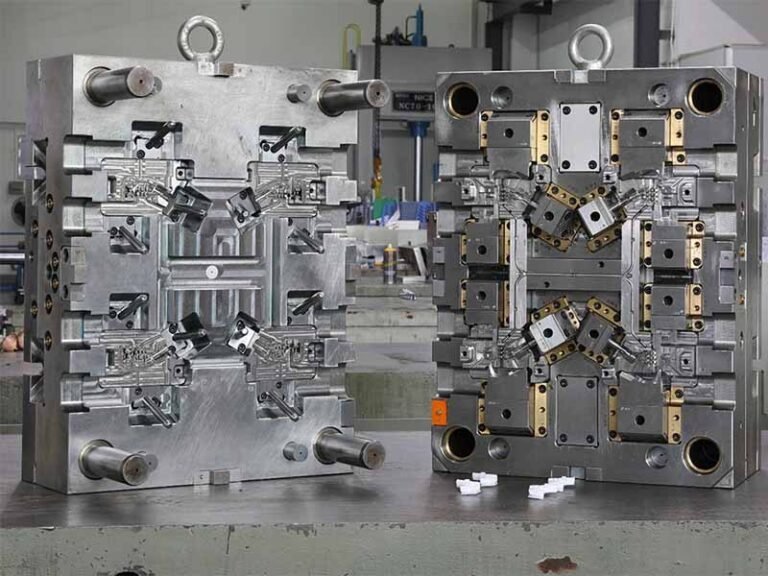

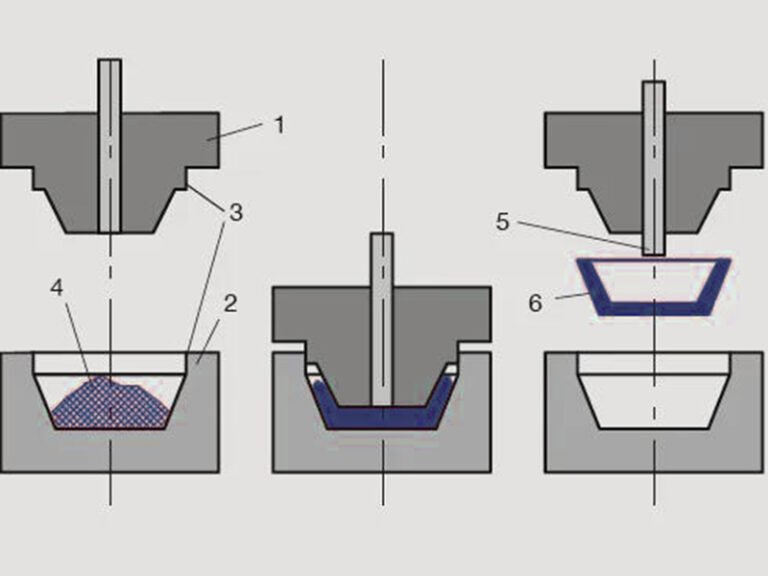

- Injection Molding

- Overmolding

- Insert Molding

- CNC Machining

Available Material

Materials can be upgraded with anti-slip additives, soft-touch TPE overmolding, UV stabilizers, color masterbatches, or impact modifiers.

- Acrylonitrile Butadiene Styrene (ABS)

- Polypropylene (PP)

- Polyamide (Nylon PA6/PA66)

- Polycarbonate (PC)

- Thermoplastic Elastomer (TPE/TPU)

- High-Impact Polystyrene (HIPS)

- Glass-Fiber Reinforced Plastics

- Acetal (POM)

Benefits of Custom Plastic Grips

- Lightweight and comfortable to hold

- Anti-slip surface for safe operation

- Excellent durability and abrasion resistance

- Corrosion and sweat resistant

- Can include ribbing, knurling, or patterned textures

- Compatible with soft-touch overmolding

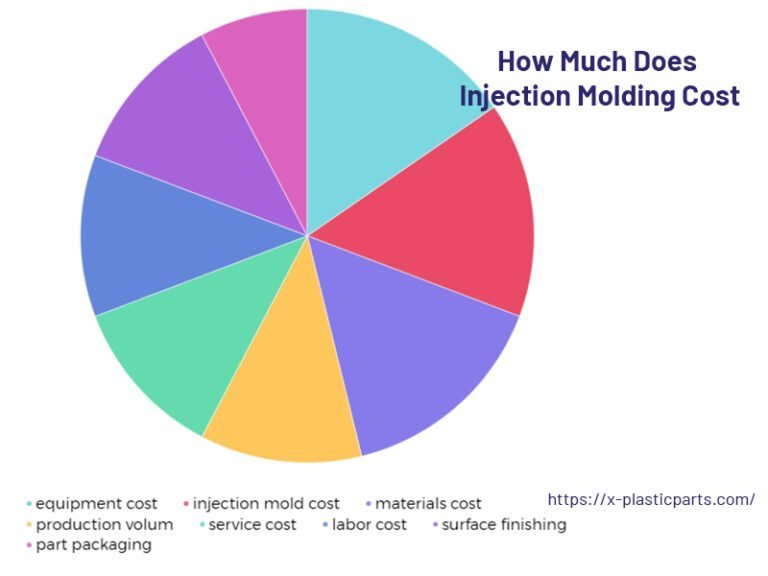

- Cost-effective for both small and large batches

Applications of Plastic Grips

Flexiparts manufactures custom grips for a wide range of industries and product categories.

- Hand tools and power tools

- Fitness and sports equipment

- Industrial machinery grips

- Medical and laboratory device grips

- Bicycle grips and handlebar covers

- Appliance and consumer product grips

- Outdoor and recreational gear

FAQs of Plastic Grips Supplier

Can you make my plastic grips softer or non-slip?

Yes. We can use TPE or TPU overmolding, ribbed patterns, knurling, or custom textures on your plastic grips to provide a soft-touch and anti-slip feel.

Can you help optimize my grip’s comfort or structure?

Yes. Although we do not create original designs, our engineering team can refine your model for comfort, strength, manufacturability, and anti-slip performance.

What material is best for high-friction or sweat-prone environments?

TPE and TPU offer superior grip, softness, and sweat resistance. Nylon provides strong mechanical stability for load-bearing applications.

Do you support slip-on or push-fit grip styles?

Yes. We can produce slip-on or push-fit grips according to the drawings, dimensions, or samples you provide. We do not offer design services, but we can manufacture exactly to your required specifications.

Do you provide prototypes before mass production?

Absolutely. We offer CNC-machined or 3D-printed samples for ergonomic evaluation and assembly testing.

What Our Customers Say

Check what our customers say about us, why they like to work with us!

Flexiparts pays attention to detail. We’re happy with their plastic and rubber molds. Communication is fast and efficient, and their support is great.

Edward

France

Working with Flexiparts has been great. The injection-molded parts are always top quality. We really appreciate your professionalism with delivery and project management

Bella

US