Drive pulleys are essential components in mechanical transmission systems, enabling the transfer of motion and power between rotating shafts. They are widely used across industries such as automotive, manufacturing, conveyor systems, and agricultural machinery. By working in tandem with belts, drive pulleys facilitate precise and efficient power transmission, reducing maintenance needs and ensuring smooth operation. Proper pulley design and alignment play a key role in reducing parasitic losses and improving overall system efficiency.

What Is a Drive Pulley?

A drive pulley is a rotating component that transmits power to a belt, which in turn drives another pulley, commonly referred to as the driven pulley. This system forms the core of a belt drive mechanism, where rotational motion and torque are transferred from the power source to a mechanical load. Drive pulleys can be classified based on the type of belt and pulley system they engage with, including V-belt pulleys, timing belt pulleys, and flat belt pulleys.

Drive Pulley vs. Driven Pulley

The main distinction between a drive pulley and a driven pulley lies in their function. The drive pulley is connected to the power source, such as a motor or engine, and initiates motion in the belt. The driven pulley, on the other hand, receives motion from the belt and transmits it to the load. Correct alignment and size ratio between the drive and driven pulleys are essential to achieve the desired speed, torque, and mechanical efficiency.

Components of a Drive Pulley

A typical drive pulley consists of several critical components:

Pulley Body: The main structure, usually made from aluminum, steel, cast iron, or reinforced plastic, is designed to withstand rotational stress.

Hub and Bore: The central section that fits onto the shaft. Hubs may feature a keyway or set screws for secure mounting. Bore dimensions must match the shaft diameter for proper alignment.

Bearings: Mounted inside the hub or end caps, they support rotation and reduce friction. Sealed types protect against contaminants.

Flanges: Raised edges on the pulley sides that guide the belt and prevent it from slipping off during operation.

Locking Assemblies: Tapered bushings or clamps prevent axial movement. They distribute the clamping force evenly.

Grooves or Teeth: Depending on the belt type, grooves or teeth are machined or molded to match the corresponding belt profile, ensuring proper engagement and torque transfer.

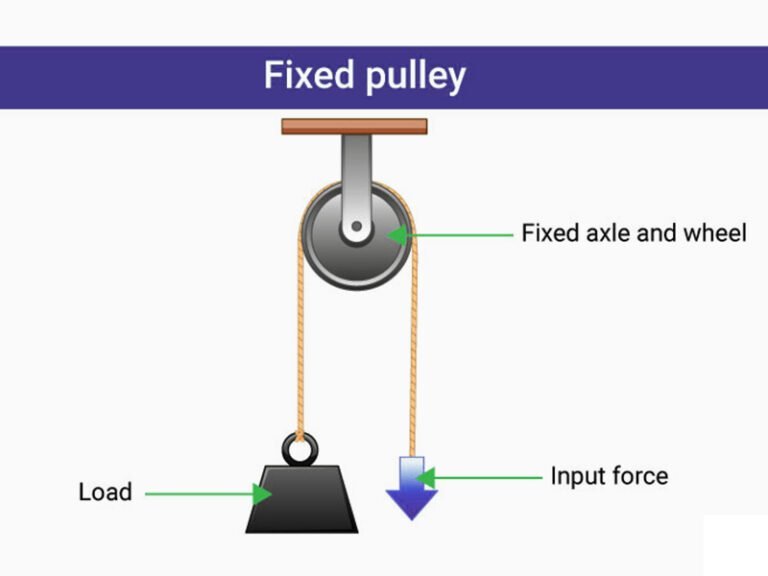

Working Principle of a Drive Pulley

The working principle of a drive pulley involves the transfer of rotational motion from the power source to a belt, which then moves the driven pulley. In a power transmission system, a plastic drive pulley can create a mechanical advantage when its diameter differs from that of the driven pulley.

- Drive Pulley and Driven Pulley of Equal Diameter: When both pulleys have the same diameter, they rotate at the same speed and transmit equal torque, making this setup ideal for simple power transfer.

- Drive Pulley Larger than Driven Pulley: A larger drive pulley makes the driven pulley spin faster but with reduced torque, suitable when a higher output speed is needed.

- Drive Pulley Smaller than Driven Pulley: A smaller drive pulley causes the driven pulley to rotate more slowly while increasing torque, ideal for applications requiring greater mechanical force.

Applications of Drive Pulleys

Drive pulleys are versatile components, appearing in a variety of mechanical and industrial applications:

Conveyor Systems: Drive pulleys power conveyor belts, moving materials efficiently across production lines in factories, packaging, and logistics.

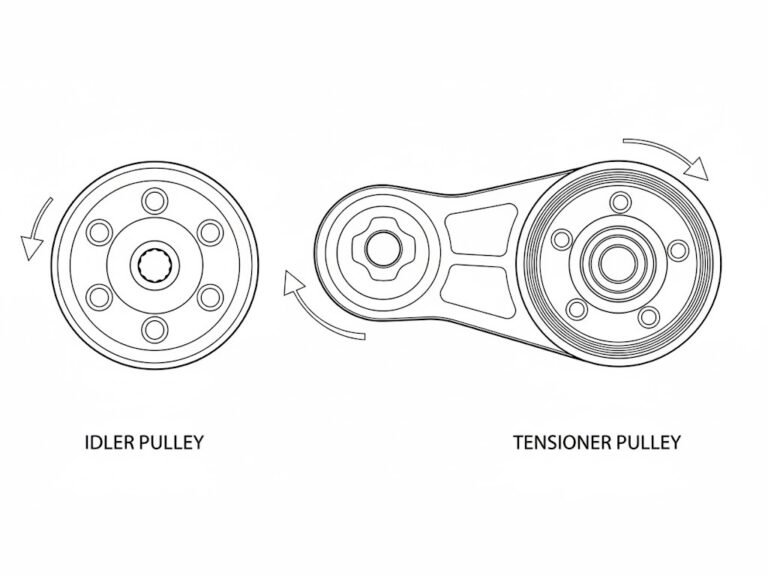

Automotive Systems: Used in engines and auxiliary systems, drive pulleys transmit power to alternators, water pumps, and other accessories.

Agricultural Machinery: Equipment such as harvesters and tractors relies on belt-driven pulleys to operate cutting mechanisms, conveyors, and other implements.

Industrial Equipment: Machines like compressors, fans, and pumps frequently employ drive pulleys for reliable power transmission.

Robotics and Automation: High-precision belt drive pulleys ensure accurate motion control in automated systems.

How to Choose the Right Drive Pulley?

Selecting a suitable belt drive pulley requires attention to several factors:

- Material: Choose materials based on load requirements, operating conditions, and environmental factors. Metals such as aluminum or steel are suitable for high-load or high-temperature environments. Plastic or reinforced polymers are appropriate for lightweight, low-load applications.

- Belt Compatibility: Ensure the pulley groove or tooth profile matches the belt type, whether it is a V-belt, flat belt, or timing belt. Correct engagement prevents slippage and uneven wear.

- Pulley Diameter and Speed Ratio: The drive and driven pulley diameters determine speed and torque. Accurate calculation ensures the system operates at the desired performance levels.

- Manufacturing Process: Drive pulleys can be machined, die-cast, or injection-molded. Machined pulleys offer high precision and durability, while injection-molded plastic pulleys provide lightweight, corrosion-resistant options.

- Environmental Conditions: Consider factors such as dust, moisture, temperature extremes, and chemical exposure when selecting materials and finishes.

- Load and Torque Requirements: Ensure the pulley and belt can handle the required power transmission without premature wear or failure.

Advantages of Choosing a Custom Manufacturer

Choosing a custom manufacturer provides solutions beyond standard catalog items, allowing precise adjustments to bore sizes, groove counts, and materials. With in-house tooling, lead times are shorter, while strict quality control ensures consistent tolerances. Engineering support, including FEA analysis for stress distribution, helps optimize part performance. Additionally, flexible production volumes make it easy to handle both prototypes and full-scale runs.

Conclusion

In practical applications, drive pulleys may face various challenges during long-term operation. Common issues include signs of wear and tear, noise and vibration caused by misalignment, overheating due to poor lubrication, and the need to replace faulty or damaged pulleys. Regular inspection and preventive maintenance are essential to keep the system running efficiently and to extend component lifespan.

Working with an experienced manufacturer such as Flexiparts ensures reliable solutions, high-quality materials, and customized drive pulley designs that minimize these problems and deliver stable, long-term performance in demanding industrial environments.