Rubber grommets are small yet essential components used in various industries. But what exactly are they for? In this article, we’ll explore the many uses of rubber grommets and how custom rubber grommets are tailored to meet the specific needs of different applications.

What Is a Rubber Grommet?

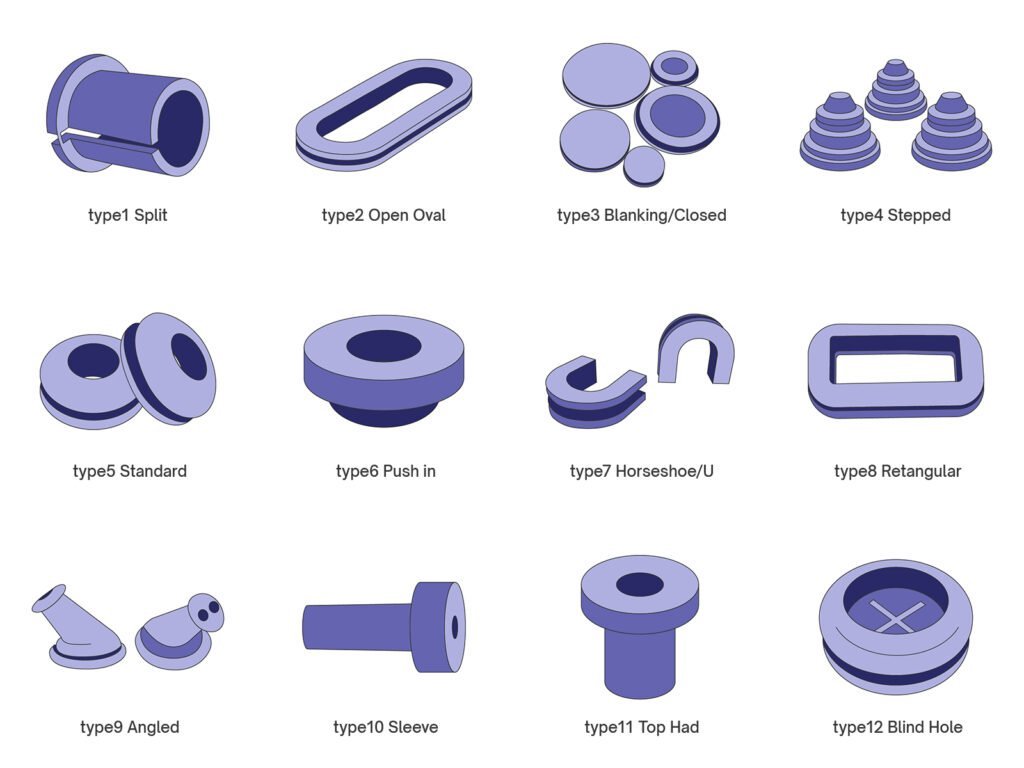

A rubber grommet is a small, circular component designed to be fitted into holes to protect wires, cables, or hoses from sharp edges and friction. It provides a safe passage that reduces wear, prevents electrical exposure, and minimizes vibration. Common advantages of rubber grommets include durability, flexibility, insulation, heat resistance, weather resistance, and easy installation, which make them widely used in automotive, electrical, construction, and industrial applications.

What Are Rubber Grommets Used For? Their Core Functions

Rubber grommets are remarkable for their versatility. Their fundamental functions include:

1. Protection from Abrasion and Cuts

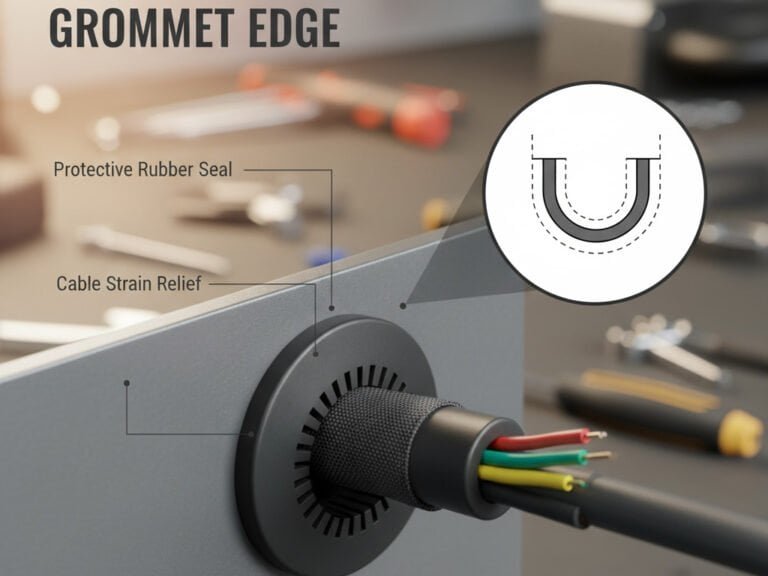

When cables, wires, or pipes are routed through sharp or rough holes, the grommet provides a buffer layer that prevents direct contact with abrasive edges. This significantly reduces wear and tear, preventing frays, cuts, and potential failures.

2. Vibration Dampening and Isolation

In environments with moving machinery or engines, vibrations can cause damage or noise. Rubber grommets absorb and isolate these vibrations, improving equipment longevity and reducing operational disturbances.

3. Electrical Insulation

Rubber grommets electrically insulate wires passing through metal or conductive surfaces, reducing the risk of shorts, shocks, or electrical interference.

4. Sealing Against Environmental Factors

These grommets help seal holes against moisture, dust, and contaminants, protecting sensitive equipment or wiring in harsh environments.

5. Cable Management and Secure Fixation

Besides protection, grommets help organize and secure cables and hoses, preventing unwanted movement or disconnections.

Applications of Rubber Grommets Across Industries

The versatility of rubber grommet use shines through in its wide-ranging applications across industries. Below, we explore how these small components make a big impact in various sectors.

Automotive

Rubber grommets protect wiring harnesses, fuel lines, and brake lines from sharp edges and vibrations in vehicles. They prevent cable fraying in engine compartments and dashboards, ensuring reliable electrical connections and reducing maintenance costs.

Electronics

In electronics, rubber grommets are used to shield cables in devices like computers and control boxes. They prevent wire damage, provide insulation, while maintaining protection against dust and moisture ingress to avoid short circuits, and organize cables for efficient, safe operation in compact systems.

Industrial Machinery

Grommets secure hydraulic hoses and air lines in heavy machinery, protecting them from abrasion and vibrations. This ensures consistent performance, reduces downtime, and extends equipment lifespan in rugged industrial settings.

Aerospace

In aerospace, rubber grommets safeguard wiring and hydraulic lines in aircraft. They withstand extreme temperatures and vibrations, ensuring safety and reliability in critical systems where failure is not an option.

HVAC and Appliances

Rubber grommets are used to reduce noise and protect cables or hoses in HVAC units and appliances like refrigerators. They seal openings to block dust and moisture, enhancing durability and maintaining performance.

Telecommunications and Construction

Grommets protect cables in telecom infrastructure and construction projects, sealing against weather and ensuring reliable signal transmission. They secure wiring in buildings, supporting long-term structural integrity.

Marine

In marine environments, rubber grommets are used to provide waterproof seals for cables and hoses. They prevent corrosion from saltwater exposure, ensuring reliable operation in boats and offshore equipment.

Choose Flexiparts as a Rubber Grommet Supplier

When considering what rubber grommets are used for and where to source them, choosing the right supplier is crucial. Flexiparts specializes in customizing a broad range of rubber grommets tailored to diverse industry needs. We offer a wide range of grommet materials like rubber, EPDM, silicone, NBR, FKM, neoprene, and polyurethane to meet your specific needs. Welcome to contact us to get a custom rubber grommet solution.