Suction cup design requires selection and optimization of the cup’s shape, material, and size based on the workpiece surface and gripping requirements to ensure stable vacuum adhesion. Shape, material, and diameter are the most critical design factors, and if they do not match the workpiece conditions, standard suction cups can experience air leakage or slippage. For applications with irregular shapes, complex surfaces, or high stability requirements, custom suction cups provide greater reliability.

What is Suction Cup Design?

Suction cup design refers to the process of configuring vacuum gripping components to achieve effective adhesion in industrial systems. This involves determining parameters such as geometry, composition, and dimensions to match specific tasks. The primary function of a suction cup is to create a vacuum between the cup and the surface of the object it is gripping. This vacuum holds the object in place by creating a pressure differential between the inside of the cup and the surrounding environment. Proper design ensures that the suction cup can generate sufficient suction force to securely hold the object and remain stable throughout the task’s duration.

Key Design Factors of Suction Cup

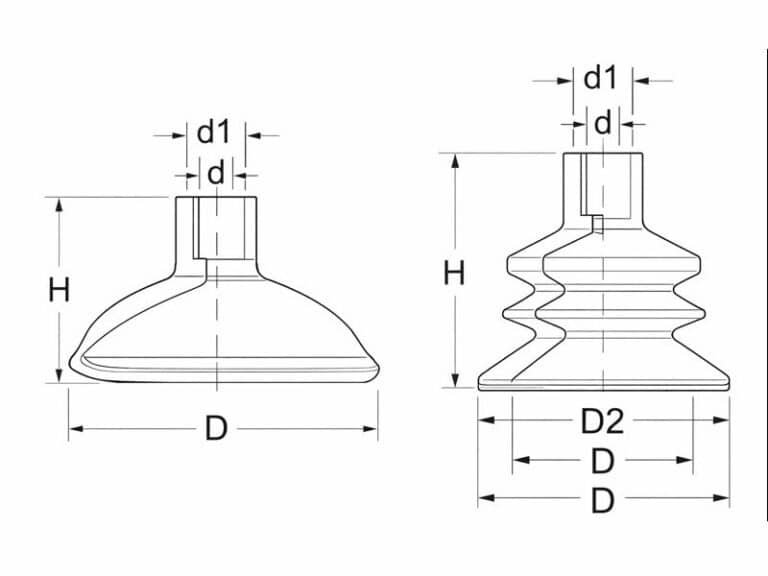

From a design standpoint, different types of suction cup are created for specific surface conditions, but their performance is ultimately determined by three core design factors: shape, material, and size.

Shape

The shape of a suction cup is crucial for its performance. It should match the surface profile of the object being handled. For flat, smooth surfaces, a standard round or bell-shaped suction cup may work well. However, for irregular or angled surfaces, customized shapes such as flat or tapered cups can offer better coverage and grip.

Material

The material of the suction cup affects its durability and suction capacity. Soft materials like silicone or rubber offer better adherence but can wear out more quickly under heavy loads. For more demanding applications, harder materials or specialized compounds may be necessary to ensure longevity and strength.

Size

The size of the suction cup directly impacts the holding force. Larger cups provide a greater suction area, which is ideal for handling heavier or larger objects. However, the size must be balanced with the workpiece’s surface area and vacuum system performance to prevent inefficiencies or excessive energy consumption.

Technical Considerations During the Design Process

Vacuum System Overall Matching

The vacuum system must be compatible with the suction cup to ensure optimal performance. A well-designed vacuum system ensures that the suction cup can maintain a consistent and reliable vacuum. The system includes a vacuum generator, distribution pipes, check valves, and pressure regulation equipment. Each component must be properly sized and aligned to work in harmony with the suction cup. The vacuum system’s performance is influenced by factors such as the size of the suction cup, the number of suction cups being used, and the overall flow capacity.

Dynamic Gripping vs Static Gripping

Suction cup design differs between dynamic and static gripping scenarios. Static gripping involves holding stationary workpieces, where a safety factor of 1.5 is often sufficient to account for minor vibrations. Materials with moderate hardness provide adequate stability in these cases.

Dynamic gripping, such as during robot movements or rotations, requires higher safety factors, typically 2.5 or more, to counteract inertial forces. Suction cup design here emphasizes friction coefficients, measured through tests, to prevent lateral shifts.

Suction Cup Layout and Multi-Point Gripping Strategies

When handling large or irregularly shaped objects, a multi-point gripping strategy may be necessary. Distributing multiple cups evenly across the workpiece prevents tilting. A minimum of four cups is common, positioned near the center of gravity to balance loads.

Common Issues and Solutions

Air Leakage

Air leakage is one of the most common issues that affects suction cups. It can occur due to several reasons, such as damage to the suction cup, a poor surface seal, or an insufficient vacuum system.

To prevent air leakage, it is essential to ensure that the suction cup is applied to a clean, smooth surface and that the vacuum system is well-maintained. For applications involving porous or rough surfaces, special attention should be given to selecting a suction cup that can conform to the surface’s texture and ensure a tight seal. Using multiple suction cups or customizing the suction cup shape for specific surfaces can also help reduce air leakage.

Slippage

Slippage arises from insufficient friction or excessive lateral forces. In the suction cup design, this is addressed by choosing materials with higher Shore hardness and increasing the safety factor. Testing the friction coefficient under load conditions verifies the solution.

Instability

Instability arises when the suction cup cannot maintain a consistent hold due to variations in surface conditions or pressure. To mitigate instability, ensure that the workpiece surface is suitable for suction and that the vacuum system is providing consistent pressure. For objects with uneven or irregular surfaces, custom suction cups designed to conform to the surface can help provide a more stable hold.

Optimization Tips for Suction Cup Design

- For multi-point gripping in a suction cup design, use four or more cups distributed uniformly to distribute the load and enhance stability. This approach reduces the required size per cup, as the formula incorporates n, the number of cups, to lower individual demands.

- Vacuum matching optimizes suction cup design by aligning generator flow with workpiece characteristics. Minimize pipeline distances and use larger diameters to sustain pressure differences, ensuring evacuation times under 0.5 seconds for efficiency.

- Material selection in suction cup design involves matching Shore hardness to the task: softer silicone for flexible adaptation on complex surfaces, and harder polyurethane for heavy-duty applications. Conduct environmental tests to confirm longevity.

Select Professional Customized Suction Cup Manufacturer

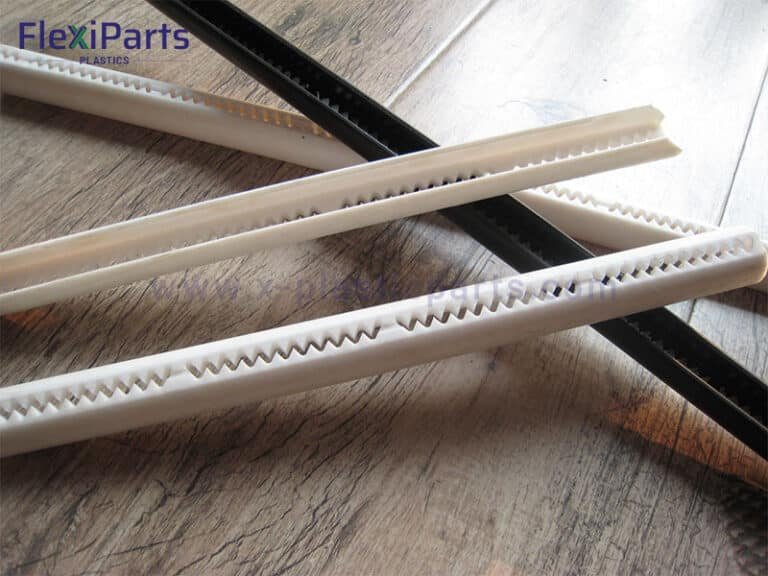

Flexiparts manufactures custom suction cups strictly based on customer-provided designs and specifications, delivering stable, production-ready components for industrial applications. Through controlled molding processes and consistent material performance, we ensure reliable vacuum gripping in real-world use.

While the suction cup design determines theoretical performance, manufacturing quality ultimately defines real-world reliability. Poor material control, inconsistent molding, or inadequate process stability can cause air leakage, slippage, and premature failure—even with a sound design. Flexiparts eliminates these risks through precise, repeatable, and scalable manufacturing execution, ensuring your suction cup performs as intended in actual operating conditions.