Pulley bearings are components used in various mechanical systems. They combine a pulley wheel with an integrated bearing to support rotational movement. In industrial and consumer applications, pulley bearings help transfer power and motion efficiently. This article covers the definition, types, advantages, disadvantages, materials, customization factors, common issues, and maintenance for pulley bearings.

What Are Pulley Bearings?

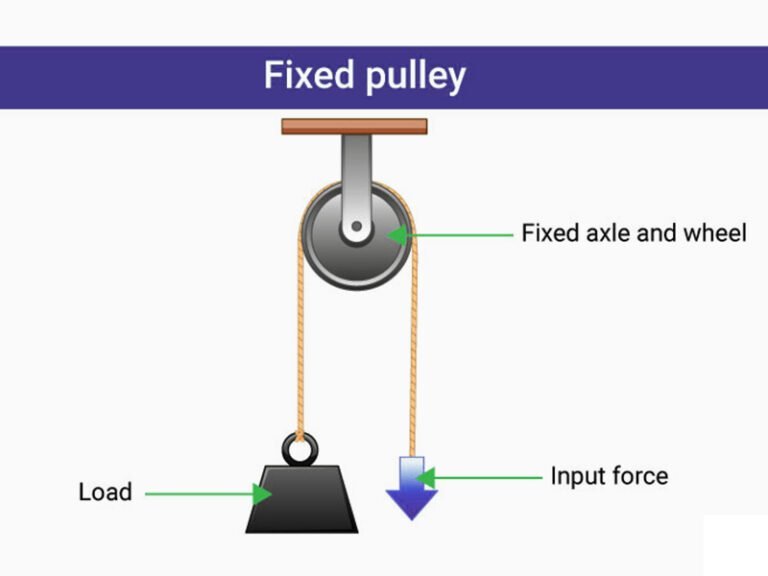

Pulley bearings consist of a wheel, often called a pulley wheel, with bearings, mounted on a shaft that allows smooth rotation. The bearing can be a ball type, roller type, or another variant, while the pulley wheel has grooves to hold belts, ropes, or cables. Plastic pulley bearings use materials like polymers for the wheel, providing specific properties suited to certain environments.

In transmission systems, pulley bearings guide and tension belts or cables to transmit power from one shaft to another. They reduce friction between moving parts, which helps maintain consistent speed and load distribution.

Main Types of Pulley Bearings

Pulley bearings are categorized based on the internal bearing mechanism. Common types include:

Ball Bearings

Ball bearings use balls between inner and outer races to handle light to moderate loads at high speeds. They provide low friction, making them suitable for applications like office machinery where smooth operation is required.

Roller Bearings

Roller bearings employ cylindrical rollers to support higher radial loads. They are used in heavy-duty setups, such as industrial conveyors, where durability under significant weight is essential.

V-Groove Bearings

V-groove bearings feature a V-shaped groove on the pulley wheel with bearings to guide belts or wires precisely. They are commonly applied in sliding door mechanisms for accurate movement.

Spherical Bearings

Spherical bearings accommodate misalignment due to their curved surfaces. They are effective in environments with vibration, such as mining equipment, ensuring reliable performance.

Tapered Roller Bearings

Tapered roller bearings manage both radial and axial loads using tapered rollers. They are utilized in systems like crane operations, where combined load support is necessary.

Sleeve Bearings

Sleeve bearings are plain bearings. They provide a cost-effective, low-maintenance solution for lighter loads and slower rotations. Plastic pulley bearings often incorporate sleeve bearings for applications where simplicity and corrosion resistance are prioritized.

Advantages and Disadvantages of Pulley Bearings

Advantages of Pulley Bearings

- Lightweight Construction: Plastic pulley bearings reduce overall system weight, which is useful in portable equipment.

- Corrosion Resistance: Materials in plastic pulley bearings withstand exposure to water and chemicals, extending service life in harsh conditions.

- Noise Reduction: By facilitating smoother movement, pulley bearings lower operational noise levels.

- Reduced Friction: Pulley bearings minimize friction between the pulley wheel and shaft, leading to smoother rotation and less energy consumption.

- Enhanced Durability: Bearings help distribute loads evenly, reducing premature wear on other system components.

- Versatile Material Options: With developments in engineering plastics, plastic pulley bearings offer corrosion resistance, lightweight properties, and chemical resistance.

- Customization: Pulley wheels with bearings can be tailored to specific applications, load requirements, and environmental conditions.

- Self-Lubricating Properties: Some pulley wheels with bearings require minimal additional lubrication, lowering maintenance needs.

- Cost-Effective Production: Injection molding for plastic components allows for economical manufacturing.

Disadvantages of Pulley Bearings

- Load Capacity Constraints: Plastic pulley bearings may not support very high loads compared to metal alternatives.

- Temperature Limits: Most plastic pulley bearings operate below 120°C, restricting use in high-heat environments.

- Potential for Brittleness: In cold conditions, some plastics become less flexible.

| Material | Key Properties | Applications |

|---|---|---|

| POM (Acetal) | High stiffness, low friction | 3D printers, office automation |

| Nylon (PA) | Impact toughness, chemical resistance | Automotive parts, gym equipment |

| PE/PP | Flexible, chemical and UV resistant | Consumer devices, light conveyors |

| TPU | Elastic, vibration dampening | Medical devices, fitness cables |

| Polyurethane | High abrasion resistance, elasticity | Heavy-duty conveyors, vibration damping |

| PTFE | Excellent low friction, chemical resistance | Corrosive environments, food processing |

| Stainless Steel | Corrosion-proof, heat stable | Marine rigging, food processing |

| Ceramics/Composites | Ultra-hard, high-heat resistant | High-temperature mining, hybrid systems |

Key Factors for Customizing Plastic Pulley Bearings

Customizing plastic pulley bearings involves evaluating several parameters to match the application:

Load Requirements: Determine static and dynamic loads. For higher loads, reinforce with fibers in materials such as nylon.

Environmental Conditions: Assess humidity, chemicals, or UV exposure. Use sealed designs or specific plastics, such as PP, for protection.

Operational Speed: Operating speeds dictate material and bearing type selection. High RPM needs low-friction options like ball-bearing integrated plastic pulley bearings.

Temperature Range: Ensure the material withstands the expected temperatures.

Noise and Vibration Requirements: Applications demanding low noise may need specific bearing designs or materials.

Mounting and Fit: Specify bore size and shape, such as D-shaped, for secure torque transfer.

Cost and Availability: Balancing budget constraints with performance needs is essential.

Common Issues and Maintenance of Pulley Bearings

Pulley bearings may encounter several common issues during service, each requiring targeted maintenance to maintain optimal performance.

Noise and Vibration

Noise and vibration in pulley bearings often result from inadequate lubrication or imbalance. Maintenance includes regular checks for alignment and applying suitable lubricants. Sealed plastic pulley bearings reduce this issue by containing lubrication.

Bearing Wear and Failure

Wear occurs from overload or misalignment, leading to failure. Inspect for surface damage monthly and replace based on load specifications. Proper installation prevents early wear in pulley wheels with bearings.

Belt Slippage and Offset

Slippage happens due to poor tension or groove mismatch. Offset can cause uneven wear. Maintenance involves adjusting belt tension periodically and ensuring alignment during setup.

Corrosion, Contamination, and Poor Lubrication

Corrosion affects metal parts in moist environments, while contamination introduces debris. Poor lubrication increases friction. Use corrosion-resistant plastic pulley bearings and clean components biannually. For lubrication, select self-lubricating types or apply grease compatible with the material.

Conclusion

Pulley bearings come in various types to suit different applications. Selecting the right one depends on factors like load, environment, and speed. Plastic pulley bearings offer advantages in many scenarios, while other materials address specific needs. Flexiparts help you customize suitable types of pulleys for your system. Contact Flexiparts for tailored recommendations.