The effectiveness of rubber grommets hinges largely on selecting the correct custom rubber grommet size. Understanding rubber grommet size and how grommets are measured is critical for selecting the right fit, preventing costly errors, and ensuring optimal performance. This article explores what rubber grommets are, common types, and how grommets are measured accurately.

What Are Rubber Grommets?

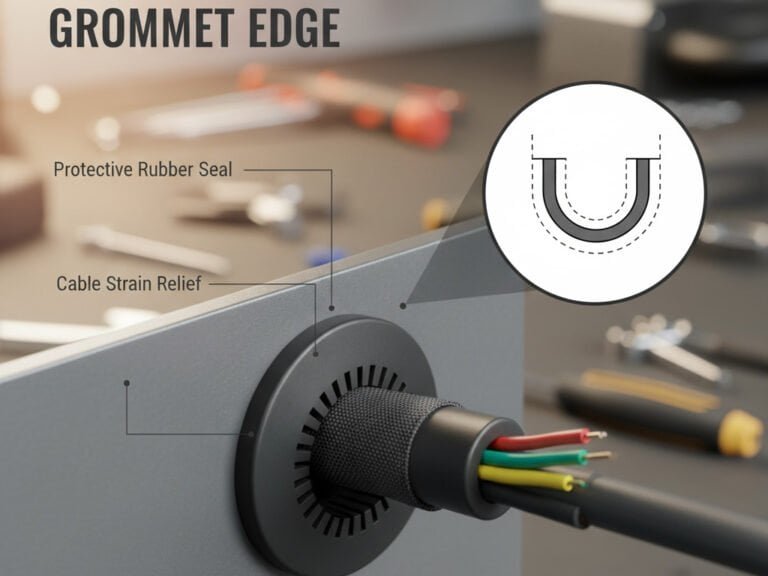

Rubber grommets are ring-shaped components designed to protect cables, wires, or pipes as they pass through holes in panels, preventing abrasion, sealing against environmental factors, or reducing vibration.

There are many different types of rubber grommets for specific applications, such as open oval grommets, blind grommets, angled grommets, horseshoe grommets, etc. Depending on the industry or application, the type of grommet required will vary. Before selecting, it is important to clearly understand which type of grommet is required.

Using the Correct Tools to Measure Rubber Grommet Size

Because grommet dimensions are often specified to the thousandth of an inch, precision tools are necessary. Commonly used instruments include calipers for measuring the outer diameter, panel thickness, and hole size, as well as pin gauges to determine the inside diameter of the grommet hole.

Without the right measurement tools, even a small deviation can cause a grommet to fit too tightly or loosely, which compromises its function.

Two Methods for Measuring Rubber Grommets

Determining the correct rubber grommet size involves two primary measurement approaches.

Measure the Panel

The first method focuses on the panel where the grommet will be installed. This approach ensures the grommet matches the panel’s specifications, preventing issues like loose fits or excessive pressure. Here’s how to measure the panel effectively:

- Measure the Hole Diameter: Measure the diameter of the hole in the panel where the grommet will be placed. This measurement directly corresponds to the outer diameter of the grommet’s groove that sits within this hole. For non-circular holes, take measurements at multiple points to confirm the shape and size.

- Determine Panel Thickness: Use a depth gauge or caliper to measure the thickness of the panel or material where the grommet will sit. This determines the maximum depth or length of the grommet.

- Measure the Object Diameter: Measure the diameter or size of the wire, cable, or object that will pass through the grommet hole. This measurement, to be matched with the inner diameter of the rubber grommet, ensures a snug fit that prevents chafing or movement.

- Take Multiple Readings: To enhance accuracy, take several measurements and average them.

Measure the Grommet

The second method involves measuring the grommet itself to verify it matches the panel and application requirements.

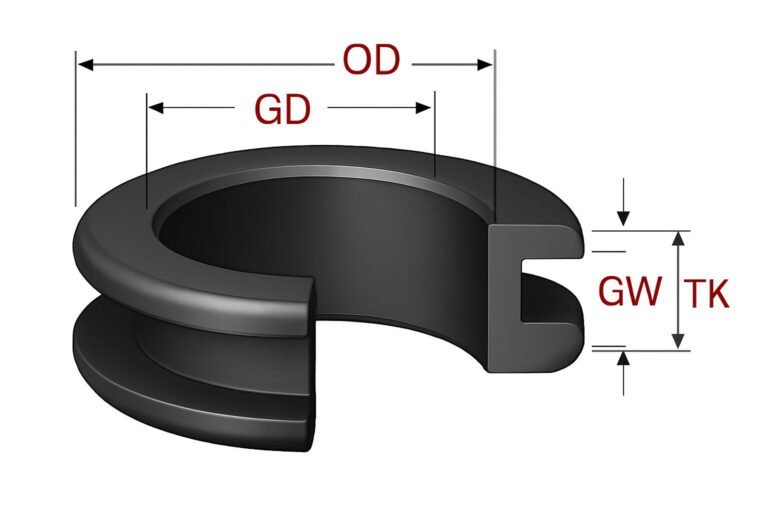

- Measure the Inner Diameter (ID): Use a pin gauge or caliper to measure the inner diameter of the grommet, which determines the size of the cable or pipe it can accommodate. For flexible materials like silicone, apply gentle pressure to avoid distorting the measurement.

- Measure the Outer Diameter (OD): The outer diameter is the total width of the grommet, including the flange. Use a caliper to measure across the widest point, ensuring it fits within the panel’s hole.

- Measure the Flange Diameter: The flange is the outer lip that secures the grommet to the panel. Measure its diameter to confirm it provides adequate coverage and stability.

- Measure the Groove Depth: The groove is the recessed area that grips the panel. Use a depth gauge to measure its depth, ensuring it matches the panel’s thickness for a snug fit.

Choose Flexiparts for Your Custom Rubber Grommet Needs

When selecting the perfect rubber grommet size and type, partnering with a reliable supplier can make all the difference. Flexiparts, as a professional on-demand manufacturer, offers extensive customization capabilities to deliver the ideal grommet solution tailored to your exact specifications. Welcome to contact Flexiparts and get a custom rubber grommet solution.