In mechanical and industrial systems, sheaves and pulleys play crucial roles in force transmission and load handling, serving applications from construction cranes to conveyor belts. While the terms “pulley” and “sheave” are often used interchangeably, understanding their distinct functions is vital in mechanical engineering, construction, and heavy machinery. Confusing these components can result in poor equipment choices, safety risks, and inefficient designs. This article explores the definitions, functions, and key differences between pulleys and sheaves.

What is a Pulley?

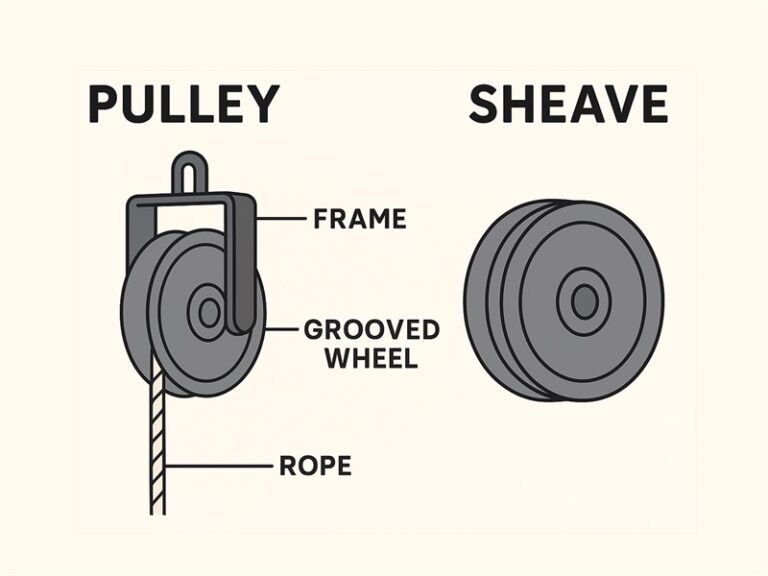

A pulley is a simple machine designed to redirect force or transmit power. It typically consists of a wheel with a grooved rim, mounted on an axle or frame, through which a rope, cable, or belt passes. The materials used can vary widely, but a plastic pulley is often chosen for tasks that don’t require high strength, such as in toys, fitness equipment, or light-duty lifting.

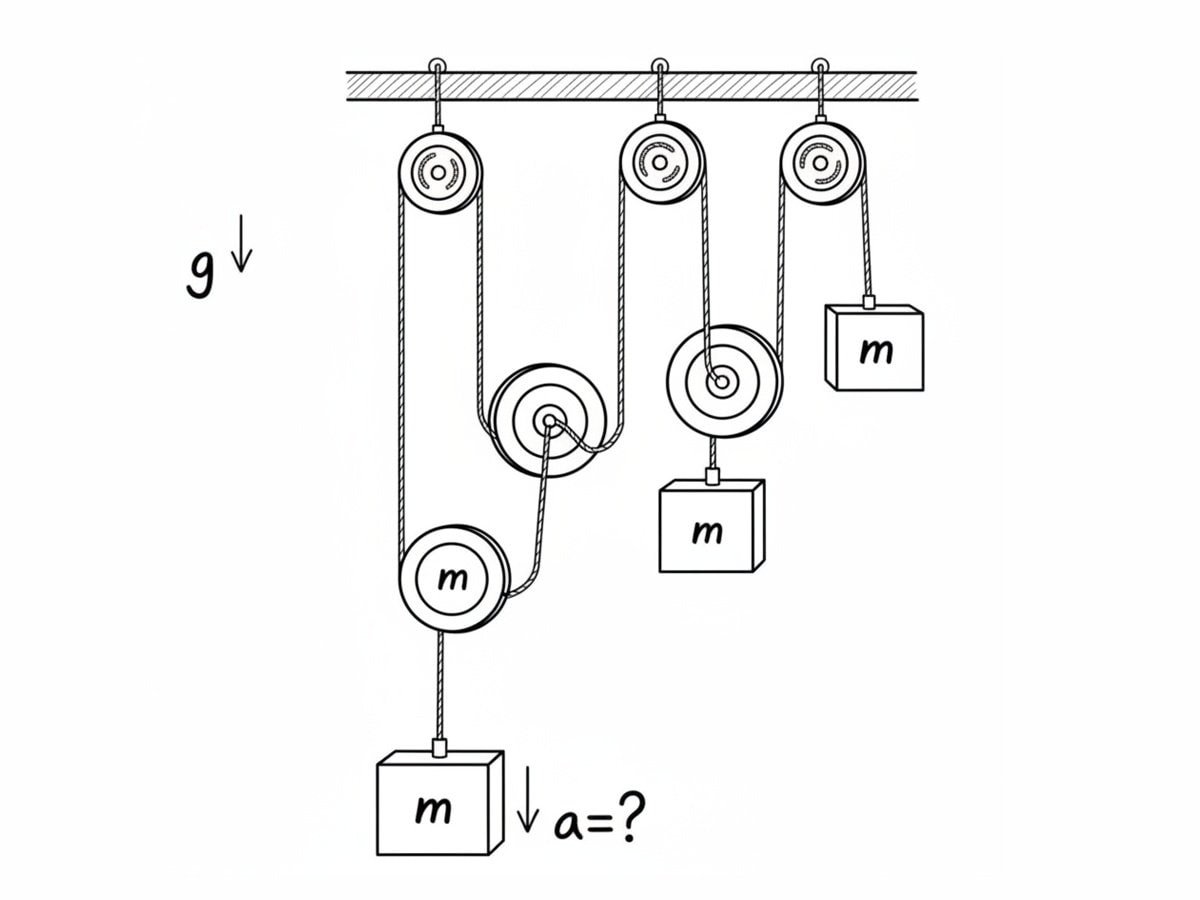

Pulleys can function as standalone units or as part of a system, such as a block and tackle, which combines multiple pulleys to amplify mechanical advantage. The design allows pulleys to reduce the effort required for tasks like lifting heavy loads or transferring motion in machinery.

Uses of Pulleys

Pulleys serve several critical functions in mechanical systems:

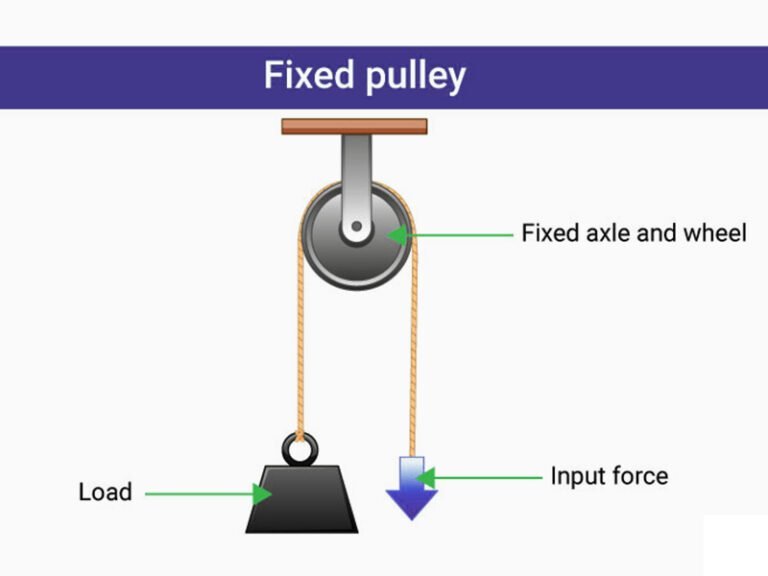

- Changing Force Direction: A pulley can redirect force, allowing a downward pull to lift an object upward, as seen in flagpoles or well systems.

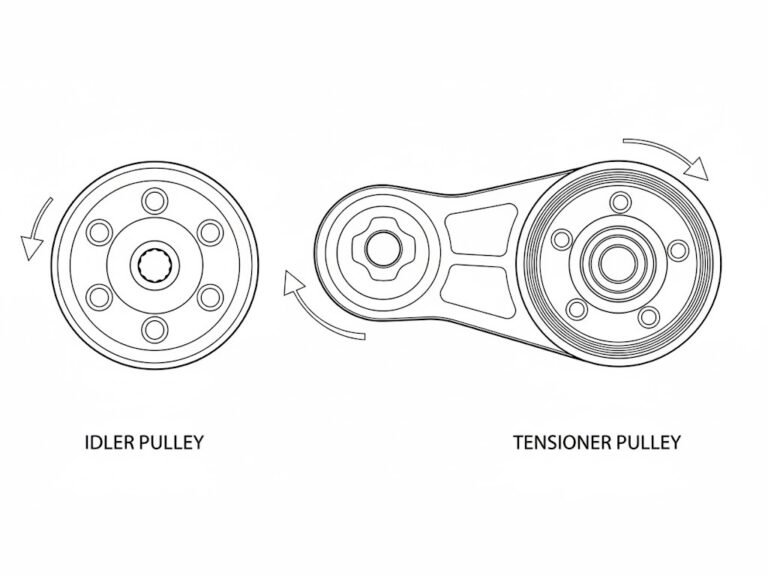

- Transmitting Power: In machinery like conveyor belts or vehicle engines, pulleys transfer rotational energy between components.

- Lifting Heavy Objects: In cranes and hoists, pulley systems multiply force, enabling the lifting of heavy materials with minimal effort.

What is a Sheave?

A sheave is a grooved wheel, typically made of metal or durable plastic, that forms a critical component of a pulley system. A sheave specifically denotes the wheel that holds and guides a rope, cable, or belt. Sheaves are designed to guide the rope or belt’s smooth movement along its groove, minimizing friction and wear. They are often replaceable components within a pulley, particularly in high-wear applications.

How Do Pulleys and Sheaves Work Together?

The sheave, as the grooved wheel, rotates within the pulley’s frame or housing, guiding the rope or belt along its path. The pulley’s axle and frame provide structural support, ensuring the sheave remains stable under load. This interaction is critical in applications like cranes, where the sheave’s smooth rotation reduces friction, while the pulley system distributes the weight of the load.

Sheaves and Pulleys: What’s the Difference?

To clarify the distinction between these commonly confused terms, the following table appropriately introduces the terms pulley vs sheave and highlights their fundamental differences.

| Aspect | Pulley | Sheave |

|---|---|---|

| Definition | A complete system with a wheel and axle | A grooved wheel within a pulley |

| Function | Redirects force, transmits power | Guides ropes or belts, reduces friction |

| Application | Used alone or in systems (e.g., block and tackle) to lift loads or transfer power | Found inside pulleys, crane blocks, and belt systems |

| Scope | Entire mechanism | Single component of the pulley |

| Mechanical Advantage | Achieved through pulley systems with multiple sheaves | Contributes to smooth operation and load distribution |

Choosing the Right Components

Selecting the appropriate pulley or sheave depends on the application’s requirements. Factors like load capacity, rope or belt type, and environmental conditions (e.g., exposure to moisture or extreme temperatures) influence material and design choices.

Conclusion

A pulley is the complete mechanism that redirects force or transmits power, while a sheave is the grooved wheel that guides the rope or belt within pulley. Flexiparts custom injection molded lightweight and durable pulleys. Contact Flexiparts and get a tailored pulley injection molding solution.