In both traditional machinery and certain modern equipment, the cone pulley remains a widely used mechanical component for simple and reliable speed variation. Although many industries have shifted to electronic or hydraulic speed control, the cone pulley still offers an effective solution where mechanical simplicity, durability, and predictable performance are required.

Structure and Components of a Cone Pulley

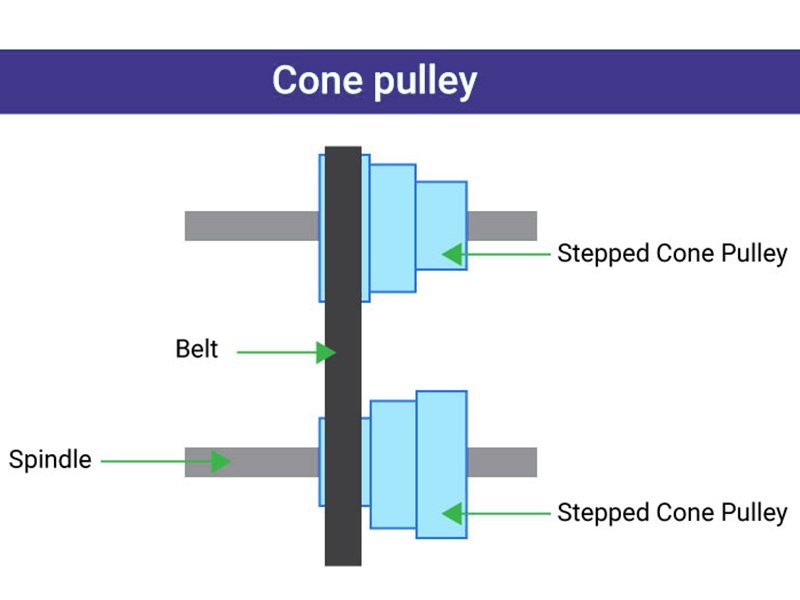

A cone pulley, sometimes referred to as a step cone pulley, consists of several pulleys of different diameters cast or machined together into a single, tapered assembly. A typical cone pulley system consists of two main parts: a driving step cone pulley and a driven step cone pulley mounted on parallel shafts. Each pulley has several steps of different diameters machined on the same hub, usually three to six steps.

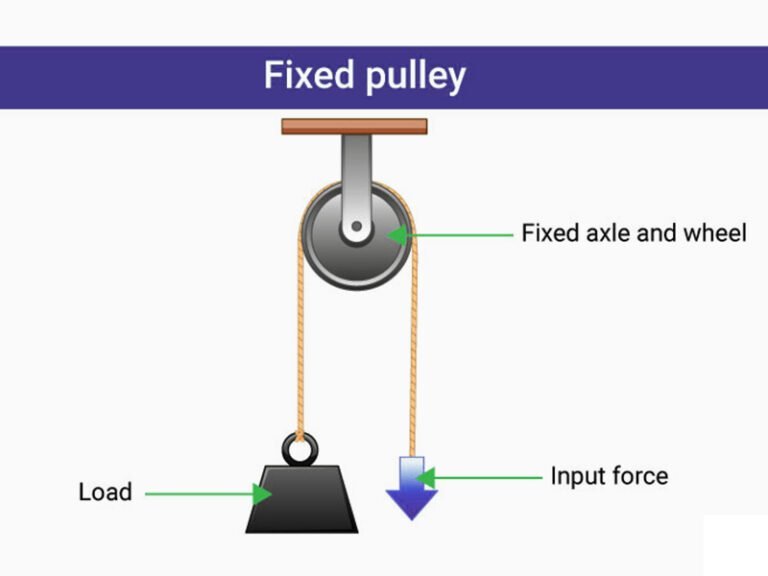

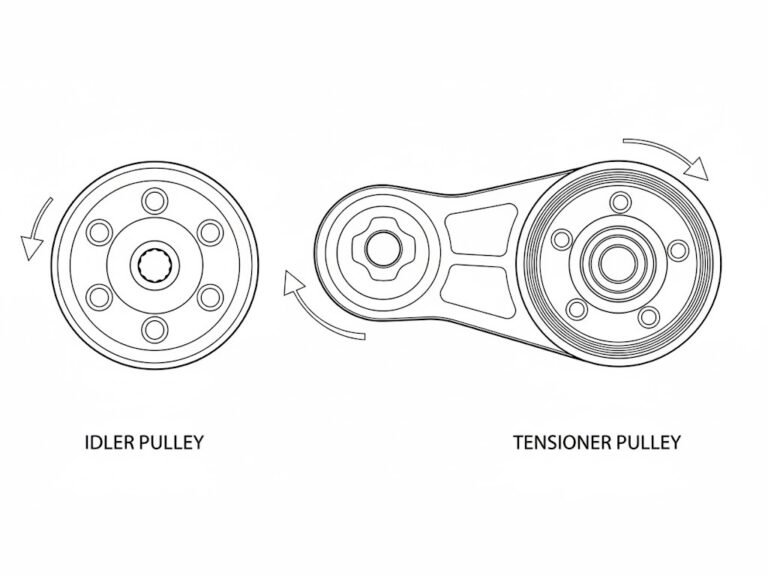

The two pulleys are arranged with steps in opposite directions. A single open flat belt (or sometimes a crossed belt) connects them. To change speed, the operator moves the belt to a different pair of steps using a belt shifter or striking fork. Belt tension is maintained by adjusting the distance between shafts or by an idler pulley.

How a Cone Pulley Works?

The operating principle of a cone pulley is based on the change in speed ratio that occurs when the working belt is shifted between steps of different diameters. When the belt moves to a larger diameter on the driver pulley and a smaller diameter on the driven pulley, the output speed increases. Reversing this relationship produces a lower output speed.

A step cone pulley typically has matching, inverted steps on both the motor side and the spindle side. When the belt is moved from one step to another, the speed changes in a predictable manner because the ratio between the steps remains constant. The process does not require intricate mechanisms or continuous adjustment. The speed remains stable as long as the belt tension is maintained.

Advantages of Using a Cone Pulley

The cone pulley continues to be used because it provides several practical benefits that meet the needs of many types of machinery:

1. Simple Structure

The system contains only essential components, making it easy to install, operate, and maintain. It does not depend on electronics or fluid systems, reducing the likelihood of unexpected failures. The predictable mechanical design also allows users to diagnose issues quickly.

2. Multiple Speed Options

Because each step represents a different diameter, a single-step cone pulley can provide several fixed speed levels. A 4-step cone pulley, for example, delivers four distinct spindle speeds, which is particularly beneficial for machine tools that require slow and fast operations based on material type.

3. Low Maintenance Requirements

The pulley itself requires very little maintenance aside from occasional cleaning and inspection. The belt may need periodic replacement, but overall, the system has fewer parts that can wear out compared to gearboxes or variable frequency drives.

4. High Durability

The pulley is commonly made from cast iron, steel, or aluminum alloys, offering long service life even in demanding environments. Machines equipped with cone pulleys often operate for decades with minimal changes to the pulley system.

Limitations of the Cone Pulley System

Despite its usefulness, the cone pulley also has several limitations that should be considered:

1. Manual Speed Changes

The operator must typically shut down the machine before adjusting the belt. This requirement may reduce productivity in operations that need frequent speed changes.

2. Limited Number of Speed Levels

The number of speeds is determined by the number of pulley steps. A4-stepp cone pulley provides four fixed speeds, which might not be sufficient for applications that need continuous or highly precise adjustments.

3. Potential Belt Slippage

Belt-driven systems can slip if tension is not maintained. Slippage can reduce efficiency, cause heat buildup, and lower torque transmission.

4. Unsuitable for High-Torque or High-Precision Control

Cone pulleys perform well for medium-duty mechanical operations but may not be ideal for heavy industrial loads or applications requiring extremely accurate speed regulation.

Design and Selection Guide

Design and choosing the right custom cone pulley involve considering several design factors that influence performance, durability, and efficiency. The following elements should be evaluated:

Diameter and Speed Ratio

The speed ratio between the driver and driven pulleys determines the machine’s output speed range. A wider diameter difference enables larger speed variation. When selecting a step cone pulley, consider the lowest and highest speeds required and the number of intermediate levels needed.

Materials Selection

The material of a cone pulley affects its weight, strength, and resistance to wear and corrosion.

- Cast iron is stable and absorbs vibration well, making it suitable for medium-to-heavy machine workloads.

- Steel provides higher strength for applications that require greater torque.

- Aluminum is lighter and corrosion-resistant, which helps when lower inertia or easier handling is needed.

- Non-metal options such as nylon and reinforced plastics reduce weight, run quietly, and work well in light-duty environments.

- Polyurethane can reduce belt wear but is generally limited to lower loads.

- Composite materials with glass or carbon fiber offer a strong, lightweight, and corrosion-resistant alternative.

The final choice depends on load requirements, working conditions, and maintenance expectations.

Belt Type and Size

The belt influences power transmission efficiency and overall system performance.

- V-belts offer better grip and reduced slippage under moderate to high loads.

- Flat belts run smoothly and are commonly used in lighter mechanical systems.

- The belt width and thickness must match the pulley groove dimensions.

- Correct belt tension ensures efficiency and reduces wear.

Distance Between Shafts

The shaft center distance affects belt tension, alignment, and the ease of switching between steps. If the shafts are too close, the belt may slacken during operation. If too far apart, excessive tension may shorten the eifespan. Center distance must allow proper belt tension at both extreme positions.

Common Application Scenarios

Cone pulleys remain in daily use in:

- Classic machine tools: drilling machines, sensitive drilling heads, small lathes

- Material handling: conveyor speed adjustment, packaging equipment

- Textile machinery: spinning and weaving drives

- Woodworking machines: band saws, planers

- Agricultural equipment and light industrial drives where 4–6 speed steps are sufficient

Conclusion

The cone pulley remains a practical and dependable speed-control mechanism in a wide range of machines. Its mechanical simplicity, low cost, and proven reliability make it a valuable component in both older and modern equipment. Although it has some limitations, it continues to serve reliably in applications that do not require complex or continuous speed adjustment. Flexiparts custom-manufactures a full range of metal and non-metal cone pulleys. Welcome to contact us and get a custom solution.