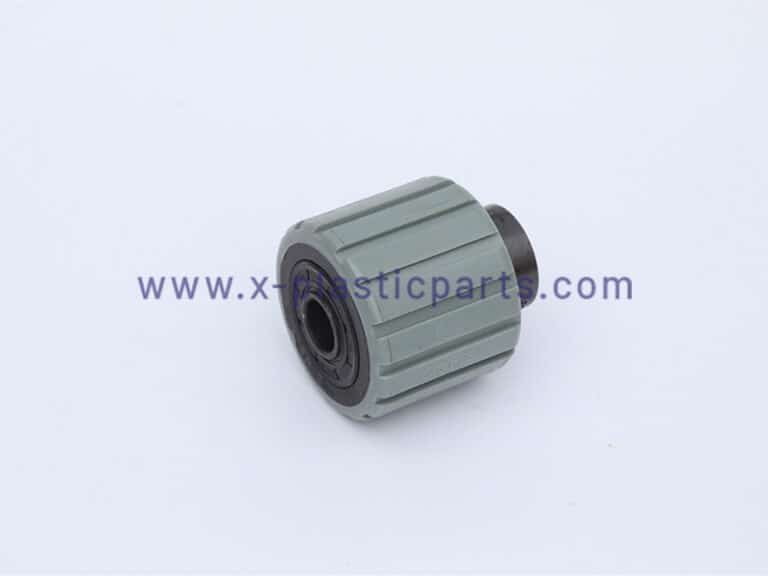

Plastic bushings are components used in mechanical systems to support and guide moving parts. They reduce friction, wear, and provide smooth, efficient operation of machinery and equipment. These simple and highly effective parts are widely used across industries such as automotive, aerospace, medical devices, and more.

What are Plastic Bushings?

A plastic bushing is a type of bearing that is made from durable plastic materials. These bushings are typically used in machinery to reduce friction between moving parts, providing smoother and quieter operation.

Common Plastic Bushing Materials

Plastic bushing materials include several types of polymers, each selected based on specific performance needs.

- Nylon: One of the most common materials, nylon bushings are durable, wear-resistant, and have a high melting point. They are often used in applications where strength and longevity are important.

- PEEK: PEEK provides high temperature resistance up to 482°F and chemical stability. It is ideal for demanding environments.

- PTFE: Known for its excellent chemical resistance and low friction properties, PTFE is used in applications requiring resistance to harsh chemicals or extreme temperatures.

- POM: Acetal plastic is another material often used for bushings due to its high stiffness and strength, along with excellent dimensional stability. It is commonly used in high-precision mechanical systems.

- UHMW: UHMW bushings are highly resistant to wear and impact, making them ideal for applications that require extreme durability.

Applications of Plastic Bushings

- Automotive industry: In automotive systems, plastic bushings are used in suspension components, steering systems, and various engine parts to ensure smooth motion and reduce wear.

- Aerospace: Plastic bushings are used in aircraft landing gear, control systems, and engine parts due to the lightweight materials and reliable performance.

- Industrial machinery: In industrial machinery, plastic bushings are widely used in moving parts to decrease friction, such as in conveyor belts, pumps, pulleys, couplings, and mixers.

- Household: Plastic bushings are used in printers, fans, and motors to ensure quiet and efficient performance.

- Food Processing: FDA-compliant materials, plastic bushings are used in food processing conveyor belts and mixers.

Main Advantages of Plastic Bushings

Plastic bushings offer several benefits when compared to metal counterparts.

Reduced Weight

Plastic bushings are much lighter than their metal counterparts. That decreases overall equipment mass and improves energy efficiency in applications.

Corrosion Resistance

Unlike metal bushings, plastic bushings are resistant to corrosion. In moist or chemical environments, plastic materials remain unaffected by water, salts, and many acids. This eliminates the need for protective coatings.

Lower Cost

Plastic bushings are often more cost-effective compared to metal bushings. The raw materials used for plastic bushings tend to be less expensive, and the manufacturing process is more straightforward and efficient. This makes plastic bushings a more economical option, especially for high-volume production.

Reduced Noise and Vibration

Plastic bushings tend to dampen noise and vibration more effectively than metal bushings. This makes them suitable for applications that require quiet operation.

Enhanced Durability

Durability under specific conditions also favors plastics; they maintain consistent friction coefficients and resist galling, where metal surfaces might score or weld together under high pressure.

Self-lubrication

Many plastic bushing materials incorporate properties that reduce friction without added oils or greases, contrasting with metal bushings that often require regular lubrication to prevent seizing.

How to Choose the Right Plastic Bushing?

Selecting the appropriate plastic bushing involves evaluating several factors tailored to industry needs. Key considerations include:

- Load Capacity: Plastic bushings should be chosen based on the load they will support. Some materials, like acetal, offer better strength for heavy-duty applications, while others, like nylon, are more suitable for lighter loads.

- Temperature Resistance: Certain plastic materials, such as PEEK, PTFE, can withstand higher temperatures, making them suitable for applications like automotive engines or high-performance machinery. Standard manufacturing can use UHMWPE for ambient conditions.

- Chemical Exposure: For environments where chemicals are prevalent, plastic bushings made from PTFE or nylon offer superior resistance to chemical degradation.

- Friction and Wear Resistance: If an application involves high friction, materials like UHMW or PTFE are ideal due to their low coefficient of friction and wear resistance.

Flexiparts Custom Bushing Manufacturing Services

As your custom bushing supplier, Flexiparts provides:

- Material Selection: Expert guidance to choose the best plastic or polyurethane for durability, temperature resistance, or chemical compatibility.

- Design for Manufacturability (DFM): Optimize your bushing designs for cost-effective production without sacrificing quality.

- Custom Production: Manufacture bushings exactly to your drawings or specifications.

- Flexible Processing Methods: Use injection molding or other methods to meet unique project requirements.

- Experience & Expertise: Years of bushing design and manufacturing experience to ensure reliable, high-performance parts.

- Scalable Production: Handle any volume, from small prototypes to large OEM runs.

With these capabilities, Flexiparts ensures every bushing is tailored for your application, from material and geometry to performance and volume.