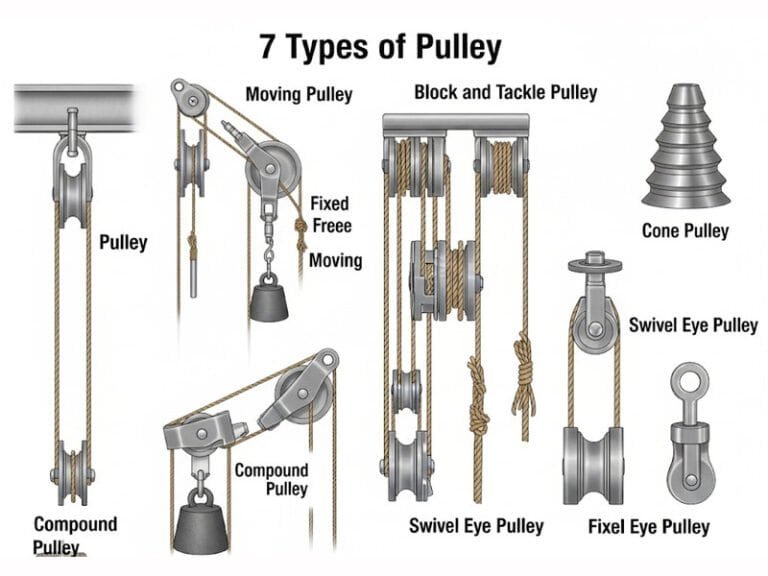

A pulley, a grooved wheel paired with a rope or belt, transforms hard tasks into easy ones by redirecting force or reducing effort. With various types of pulleys tailored to specific needs, these devices power industries from construction to marine operations. This article explores seven main types of pulleys, highlighting how understanding them can guide you in selecting or designing the ideal custom pulley for specific requirements.

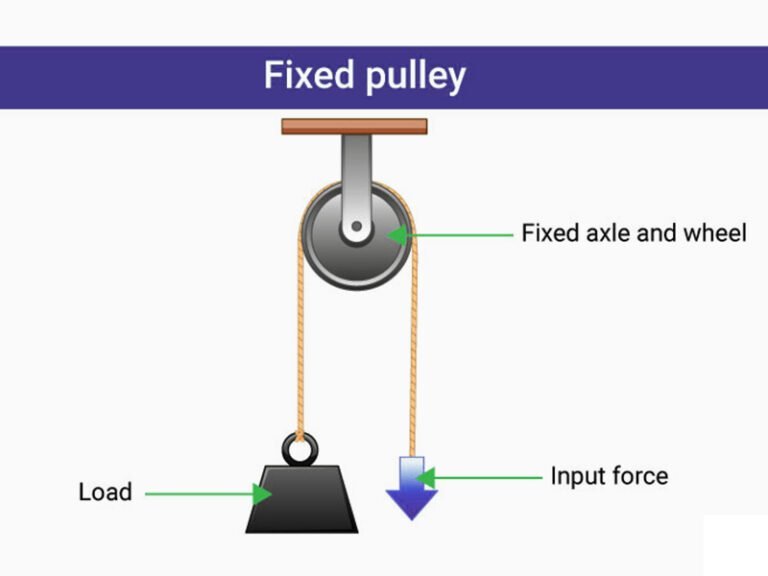

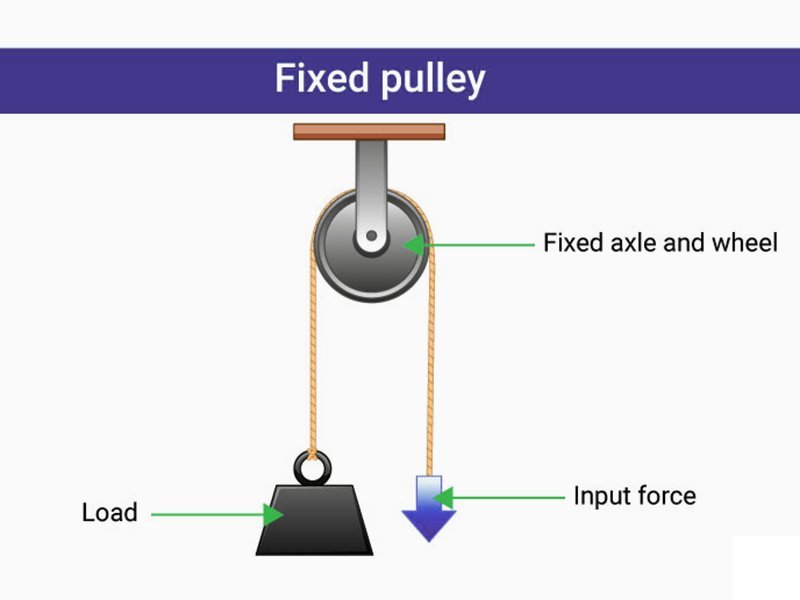

1. Fixed Pulley

A fixed pulley has its wheel mounted securely to a stationary support, such as a ceiling or frame. When the rope is pulled, the pulley simply changes the direction of the applied force without reducing the effort needed to lift the object. This type doesn’t provide a mechanical advantage in terms of force multiplication but is invaluable for redirecting force, allowing the user to pull down while the load moves up. Fixed pulleys are common in flagpoles, window blinds, and simple lifting setups.

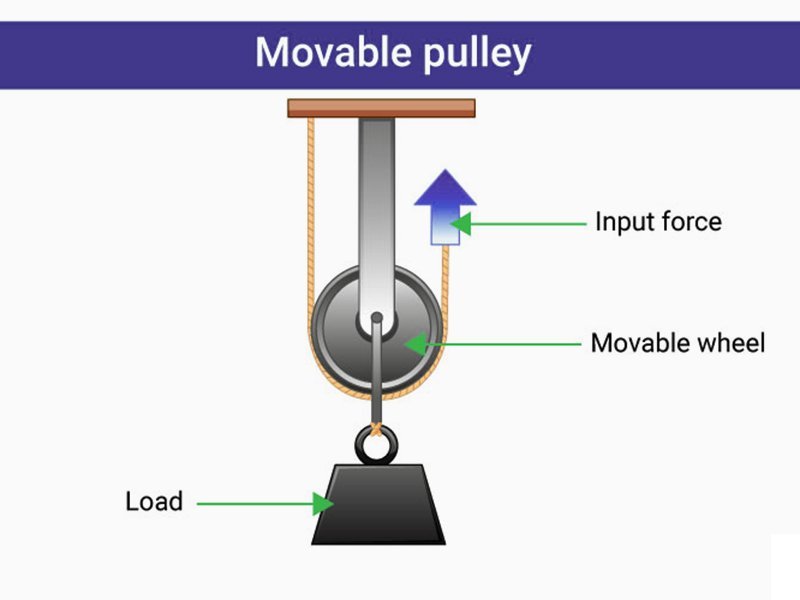

2. Moving Pulley

Unlike fixed pulleys, a moving pulley attaches directly to the load. The rope runs through the pulley, and one end is anchored while the other is pulled. This arrangement reduces the effort required to lift the load by effectively sharing the load between the rope and the pulley support. The force needed to lift the load is halved, providing a mechanical advantage of two. Moving pulleys are widely used in construction cranes and elevators for heavier lifting tasks. However, the disadvantages are increased rope length and slower lifting speed.

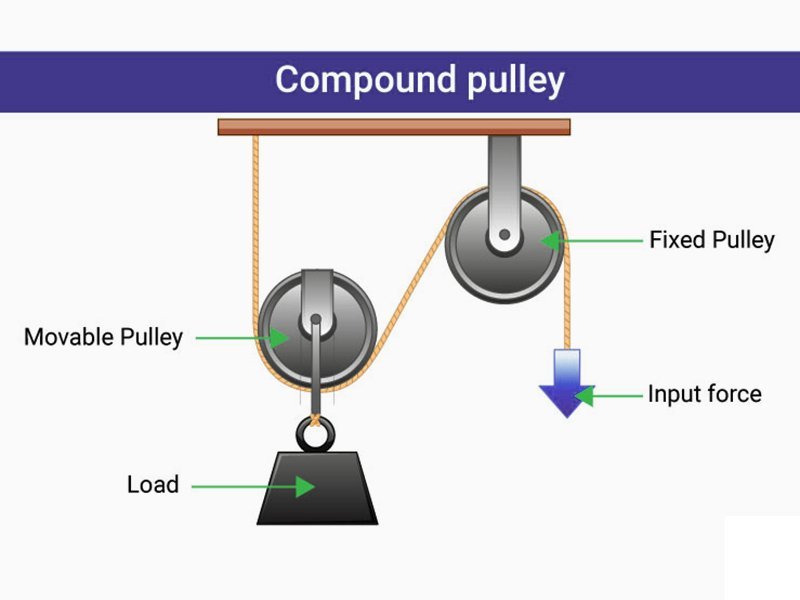

3. Compound Pulley

A compound pulley system combines fixed and moving pulleys to amplify the mechanical advantage while also changing the direction of force. By arranging multiple pulleys, the compound system allows lifting heavy loads with much less effort. The ropes run through several pulleys, distributing the weight and reducing the required input force dramatically. Compound pulleys are fundamental in applications that demand both ease of use and efficiency, such as theater rigging and heavy machinery.

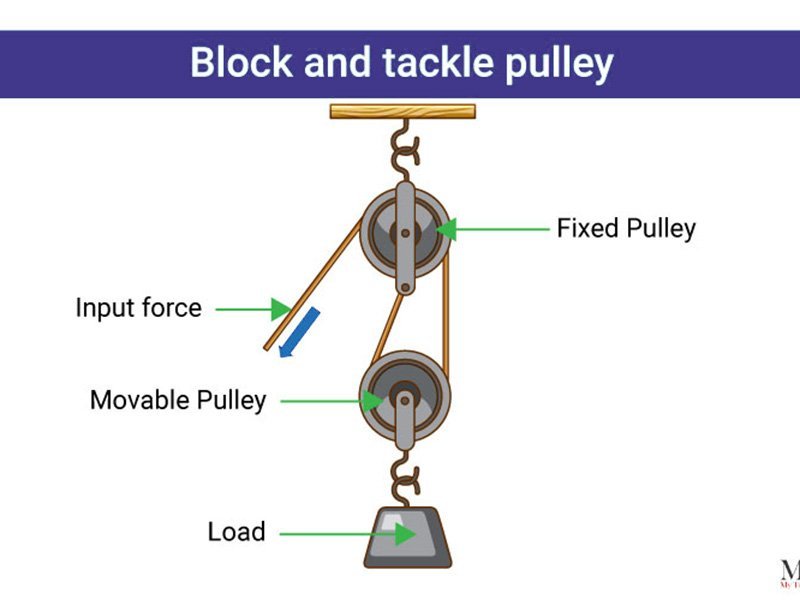

4. Block and Tackle Pulley

One of the most efficient systems, the block and tackle, consists of multiple fixed and moving pulleys mounted on two blocks. Each pulley in the system is connected by rope, drastically reducing the force needed to lift a heavy load. This arrangement also allows for smooth, controlled lifting of substantial weights and is common in maritime settings, large construction projects, and industrial hoisting equipment. The mechanical advantage depends on the number of pulleys used.

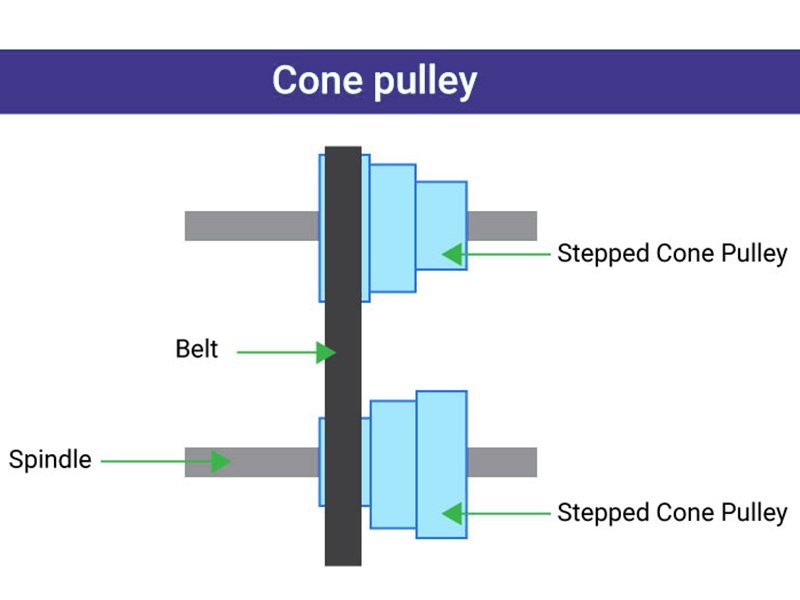

5. Cone Pulley

Cone pulleys are characterized by several pulley wheels of decreasing diameter stacked together in a conical shape. This design enables the user to change the speed and force ratio by moving the belt to different-sized wheels. The cone pulley is prevalent in machinery that requires variable speeds, such as lathes and bicycles with multiple gears. It allows seamless adjustment without changing gears manually.

6. Swivel Eye Pulley

A swivel eye pulley incorporates a mount that can rotate, providing flexibility when lifting loads that need to change direction or angle during operation. This dynamic rotation helps prevent twisting of the rope or cable and is especially useful in applications requiring frequent orientation changes. They are commonly used with fiber, nylon, or wire ropes in rigging, rescue operations, and theater equipment.

7. Fixed Eye Pulley

With a fixed eye pulley, the attachment point (eye) is stationary. Such pulleys are used in systems where stable attachment is critical, often configured with multiple pulleys to reduce effort effectively. Fixed eye pulleys are chosen for conveyor belts, lifting apparatus, and scenarios where rotation of the mount is unnecessary or unwanted.

How to Choose a Custom Pulley Manufacturer?

Pulleys come in many forms, each designed for specific force requirements and working environments. At Flexiparts, we offer an extensive selection of pulley systems, from simple fixed designs to advanced compound and block and tackle configurations. With our engineering expertise, every custom pulley we produce is tailored to match your exact mechanical and operational needs. Get in touch with us to discuss a professional custom solution for your project.