Product Categories

Custom Plastic Parts

Custom Rubber Parts

Custom PU Parts

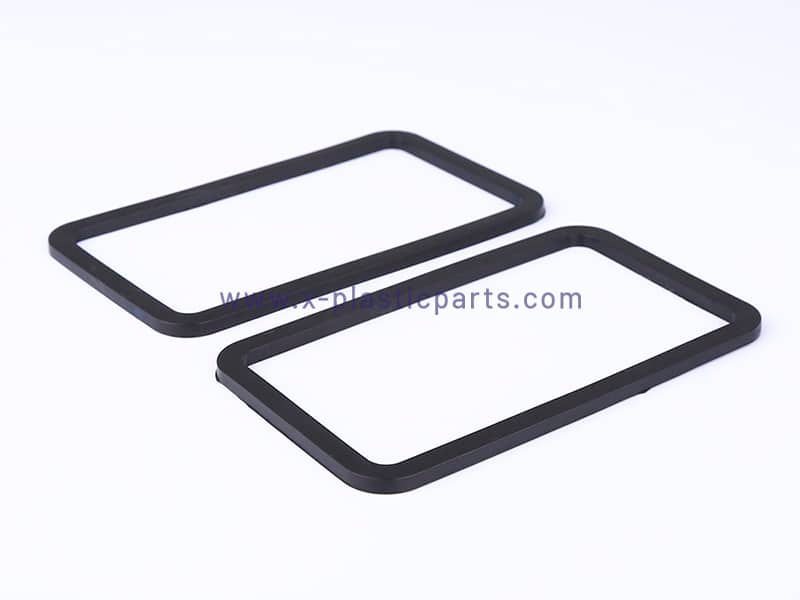

EPDM Rubber Grommets

Customized EPDM Grommet

EPDM rubber grommets offer excellent resistance to weather, ozone, and UV. They provide effective sealing, vibration dampening, and protection against environmental damage, ensuring long-lasting durability.

Flexiparts specializes in molded EPDM rubber grommets and custom injection molding, offering services from mold design to mass production. Specify size, hardness, shape, mounting style, and color to meet your needs. Please send us your 3D drawings or samples.

How To Work with Us

The key to great custom parts is collaboration. As a custom molding manufacturer, our enginnerss will stay connected with you throughout the process, and deliver products that meet your expectations.

- Send us your 2D/3D files or product concept, for an accurate quote, please send us materials, order quanity and surface requirement.

- We review your design,and send you a clear cost within 24 hours.

- Our tooling team builds the mold to your specifications, then send you T1 samples for confirmation.

- Once sample approved, we run full production under strict quality control

- Your finished parts are packaged securely and shipped to your location on time.

Related Products

Start Your Project!

Custom Plastic & Rubber Parts Manufacturer Solutions

01

Injection Molding

02

Overmolding

03

Insert Molding

04

CNC Machining

Need custom rubber, plastic, or polyurethane parts? FlexiParts offers prototyping and on-demand, low to high-volume production of high-quality, durable components. Whatever your needs, we deliver reliable custom parts on time and within budget. Start your project with us today!