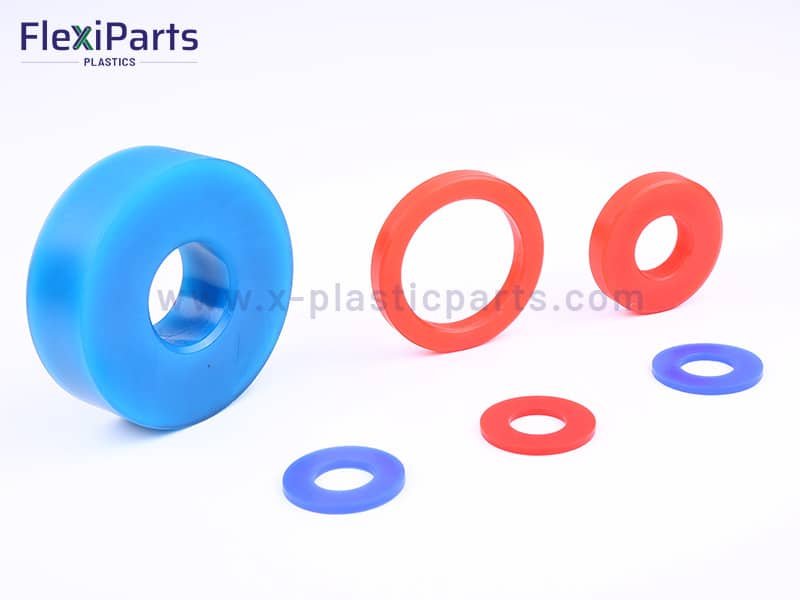

Custom Plastic Washer

Product Categories

Custom Plastic Parts

Custom Rubber Parts

Custom PU Parts

Customization Molded Plastic Washer

When standard washers don’t match your size, deform under load, or fail in harsh environments, Flexiparts provides reliable custom plastic washer solution. We manufacture plastic washers exactly to your required dimensions, thickness, and material specifications with full in-house mold making and precision machining to ensure a perfect fit, stable fastening, and long service life across electronics, machinery, automotive, and industrial applications.

Getting a custom molded plastic washer solution is easy — send us your drawing or sample, and we’ll take care of mold design, quoting, and manufacturing. Reach out anytime via our website, email, or phone to get started.

Plastic Washers for Your Personal Application

Design Plastic Washer Suggestions

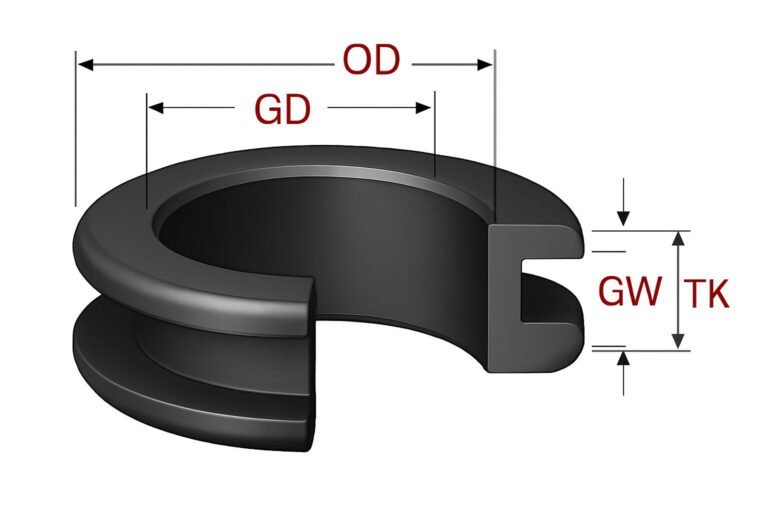

When planning a custom plastic washer, consider load distribution, fastening pressure, and environmental conditions. Choose materials based on chemical exposure, temperature range, dielectric requirements, and wear resistance. Ensure OD, ID, and thickness align with your bolt, screw, or shaft. Account for friction, compression set, and long-term dimensional stability. Plan for installation space, fastening force, and whether the washer needs to insulate, seal, or simply space components.

Manufacturing Process

- Injection Molding

- Overmolding

- Insert Molding

- CNC Machining

Available Material

- Nylon (PA6, PA66)

- Acetal (POM/Delrin)

- Polypropylene (PP)

- Polyethylene (HDPE/LDPE)

- Polycarbonate (PC)

- ABS(Acrylonitrile Butadiene Styrene)

- PTFE (Teflon)

- PVC(Polyvinyl Chloride)

- UHMW-PE

Benefits of Custom Plastic Washers

- Lightweight, corrosion-free performance

- Excellent electrical insulation and dielectric strength

- Smooth, low-friction surface

- Good chemical and moisture resistance

- Quiet operation with vibration-damping properties

- Cost-effective, consistent geometry

- Fully customizable size, thickness, and features

Applications of Plastic Washers

- Electronics and PCB assemblies

- Automotive interior and under-hood components

- Home appliances and consumer products

- Industrial machinery and fasteners

- Medical and laboratory equipment

- HVAC systems and pumps

- Marine and outdoor equipment

FAQs of Plastic Washer Manufacturer

What Our Customers Say