Custom Plastic Pulley

Product Categories

Custom Plastic Parts

Custom Rubber Parts

Custom PU Parts

Custom Molded Plastic Pulleys

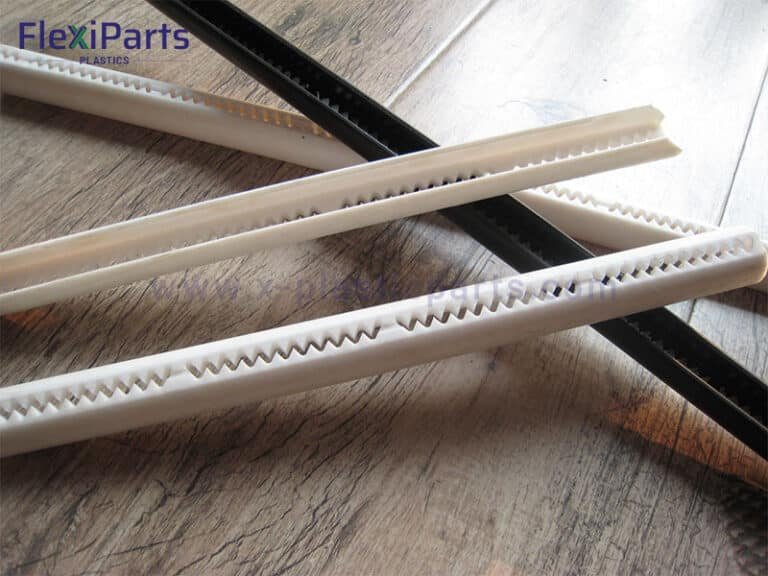

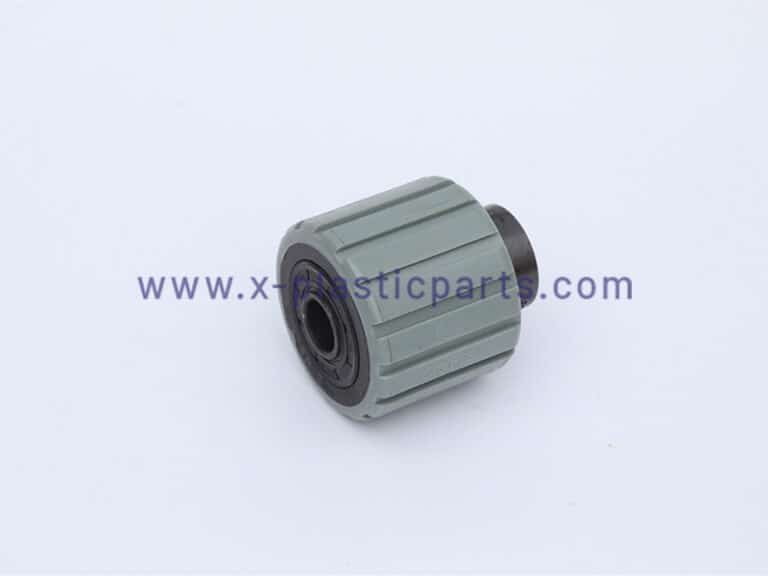

Flexiparts Plastic offers custom plastic pulleys and mold-making services designed for reliable, quiet, and efficient operation. Ideal for conveyors, automation systems, and other demanding machinery, they are lightweight, durable, corrosion-resistant, and precisely molded or CNC-machined to meet your exact specifications.

Getting a custom Plastic pulley solution is easy — send us your drawing or sample, and we’ll take care of mold design, quoting, and manufacturing. Reach out anytime via our website, email, or phone to get started.

Custom Plastic Pulley to Fit Your Application

Plastic Pulley Design Suggestion from Flexiparts Engineer

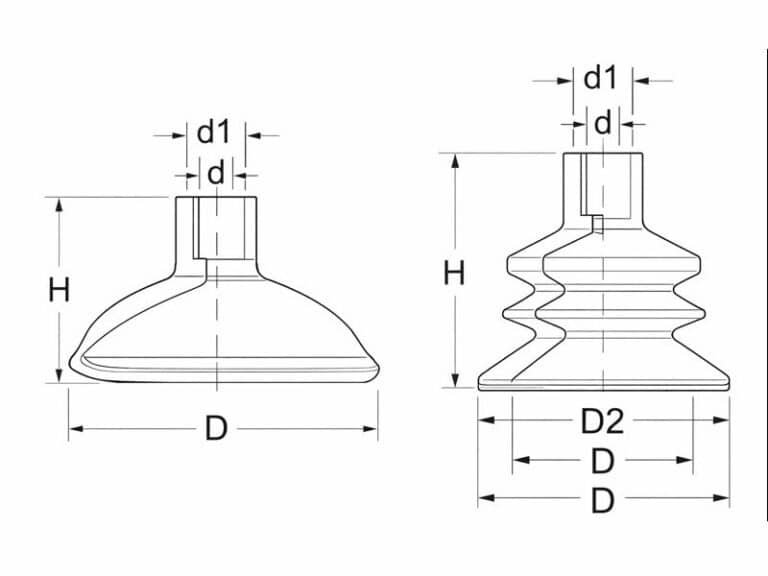

When planning a custom plastic pulley, think ahead about smooth motion, proper load support, and long-term durability. Choose materials that suit your load, speed, and environmental conditions. Make sure the diameter, width, groove profile, and bore size match your belt, cable, or shaft. Consider friction, wear, and exposure to heat, chemicals, or moisture. Also, plan for mounting style, rotation direction, and the forces the pulley will experience to ensure reliable performance and a pulley that truly meets your system’s needs.

Manufacturing Process

- Injection Molding

- Overmolding

- Insert Molding

- CNC Machining

Available Material

- Acrylonitrile Butadiene Styrene (ABS)

- High-Density Polyethylene (HDPE)

- Polyamide (Nylon PA6, PA66)

- Acetal (POM/Delrin)

- Polycarbonate (PC)

- Polypropylene (PP)

- Teflon (PTFE)

- UHMW-PE

Benefits of Custom Plastic Pulleys

- Lightweight yet durable construction

- Smooth and quiet operation

- Excellent wear and corrosion resistance

- Low maintenance and cost-effective

- Non-conductive and vibration-damping

- Customizable geometry and insert options

Applications of Plastic Pulleys

- Automation and conveyor systems

- HVAC and ventilation equipment

- Electric motors and drives

- Office and printing machinery

- Medical and laboratory devices

- Fitness and consumer equipment

- Automotive interior and control systems

FAQs of Plastic Pulleys

What Our Customers Say