Custom Plastic Cap

Product Categories

Custom Plastic Parts

Custom Rubber Parts

Custom PU Parts

Custom Molded Plastic Cap

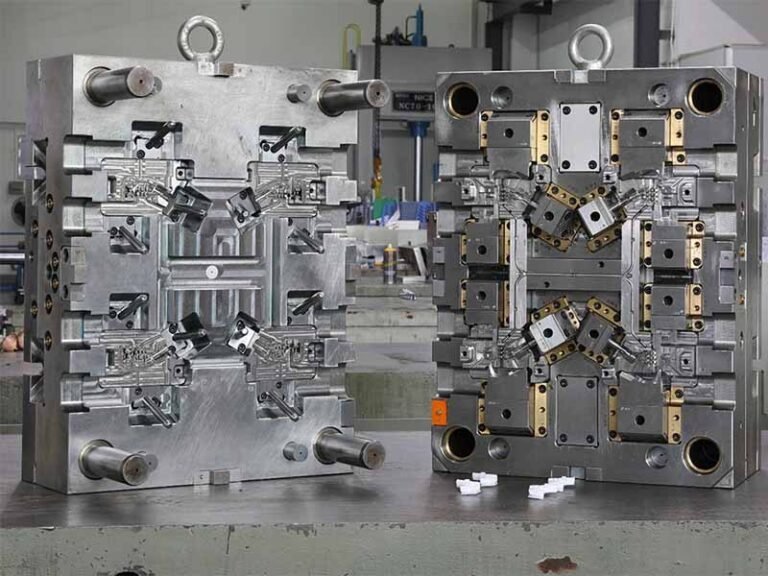

Flexiparts specializes in custom plastic caps and mold-making, offering solutions that meet your exact size, shape, and functional requirements. Lightweight, corrosion-resistant, and crafted through high-precision molding or CNC machining, our caps deliver secure sealing, impact protection, and long-lasting performance for packaging, industrial equipment, automotive parts, and consumer products.

Getting a custom plastic cap solution is easy — send us your drawing or physical sample, and we’ll handle mold design, quoting, and production. Contact us anytime via our website, email, or phone to get started.

Custom Plastic Caps to Fit Your Application

Design Plastic Cap Suggestion

When planning a custom plastic cap, consider the sealing strength, fit precision, and environmental conditions it must withstand. Select materials that align with your chemical exposure, temperature range, and mechanical needs.

Define dimensions carefully—thread profile, wall thickness, opening size, and locking mechanism must match the mating part. Think about grip style, insertion force, aesthetics, and durability. Also account for production volume, assembly method, and long-term wear to ensure a cap that performs reliably throughout its service life.

Manufacturing Process

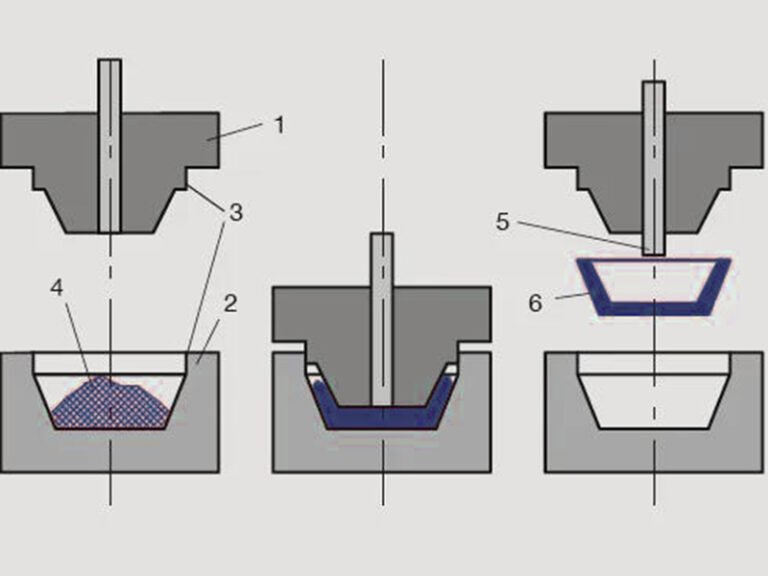

- Injection Molding

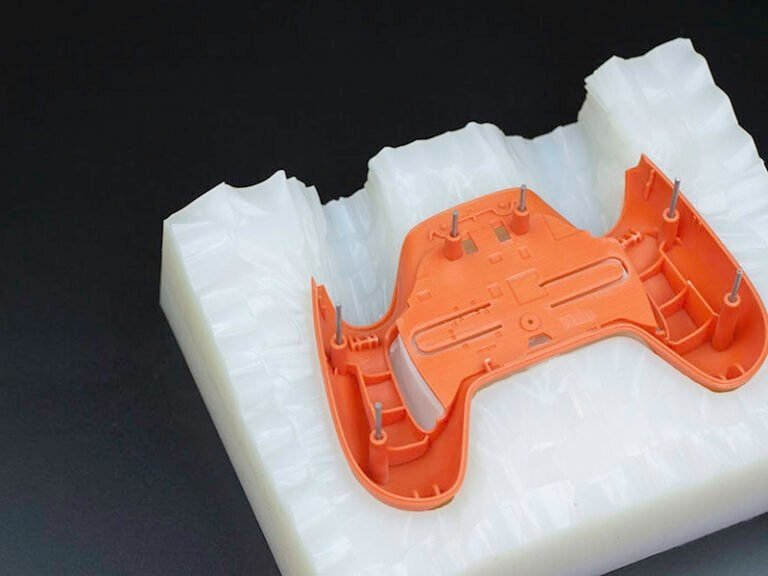

- Overmolding

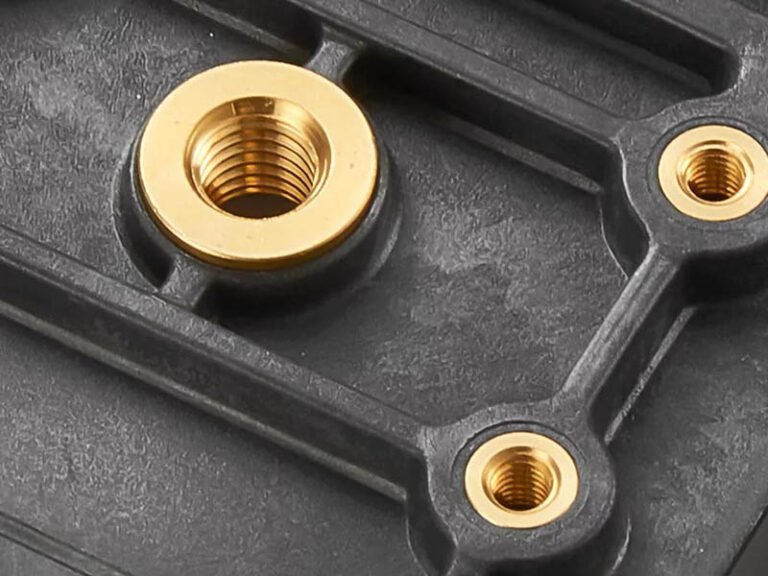

- Insert Molding

- CNC Machining

Available Material

- Polypropylene (PP)

- High-Density Polyethylene (HDPE)

- Low-Density Polyethylene (LDPE)

- Polyamide (Nylon)

- Polycarbonate (PC)

- Acrylonitrile Butadiene Styrene (ABS)

- Thermoplastic Elastomer (TPE/TPU)

- Acetal (POM)

Benefits of Custom Plastic Caps

- Strong sealing performance and precise fit

- Chemical and corrosion resistance

- Lightweight and cost-effective

- Durable and impact-resistant

- Smooth appearance and customizable colors

- Suitable for high-speed automated assembly

- Various closure mechanisms available (threaded, snap-fit, push-on)

Applications of Plastic Plug Caps

- Bottles, tubes, and packaging containers

- Automotive components and fluid systems

- Industrial pipes and fittings

- Medical and laboratory equipment

- Household and personal care products

- Electronics and machinery protection

- Outdoor and sports equipment

FAQs of Plastic Cap

What Our Customers Say