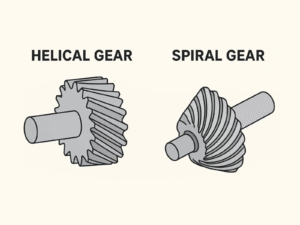

In mechanical engineering, the term spiral gear often refers to helical gears, which feature teeth angled relative to the gear axis. This design differs from spiral bevel gear systems, which handle intersecting axes. The two should not be confused. Advances in plastic materials have enabled plastic spiral gears to replace metal versions in select applications. This article examines spiral gear characteristics, operating principles, and applications, with emphasis on plastic versions and their potential.

What is a Spiral Gear?

A spiral gear consists of a cylindrical body with teeth cut at an angle to the axis. This helix angle typically ranges from 8° to 45°. The angled teeth allow gradual engagement during rotation, resulting in quieter operation, higher load-carrying capacity, and improved efficiency compared to straight bevel gears.

The spiral angle determines the direction of the thrust load. Spiral bevel gears can be designed with either a right-hand or left-hand spiral angle. Right-hand helix means the teeth slope clockwise when viewed from one end. Left-hand helix slopes counterclockwise. Gears can operate in single or double helix configurations. Double helix designs, or herringbone gears, cancel axial thrust forces.

Differences Between Spiral Gear and Helical Gear

| Aspect | Spiral Gear | Helical gear |

|---|---|---|

| Tooth surface shape | curved spiral tooth profile | Conical, curved teeth on tapered body |

| Meshing Method | Gradual line contact, axial thrust | Point contact progressing to line, side thrust |

| Application | Parallel shafts, speed variation | Intersecting shafts (usually 90°), torque direction change |

How Does a Spiral Bevel Gear Work?

The curved teeth on a gear spiral gradually engage from one end to the other as the gears rotate. This progressive engagement minimizes sudden impact and reduces vibration. The spiral angle, the degree of curvature on each tooth, determines how gradually the contact begins. A larger spiral angle allows for smoother motion but increases axial thrust, which must be managed with proper bearing design. Tooth orientation (right-hand or left-hand spiral) also defines the direction of the thrust force and the rotation pattern of the meshing gears.

Plastic Materials in Spiral Gear Applications

In recent years, plastic spiral gears have gained attention for their performance benefits in lightweight and low-noise machinery. Engineering plastics such as polyoxymethylene (POM), nylon (PA), polyetheretherketone (PEEK), and reinforced composites’ self-lubricating nature reduces friction and wear, while their resistance to corrosion and chemicals makes them suitable for environments where metal gears might degrade. Plastic materials also offer excellent moldability, allowing spiral gear manufacturers to produce complex geometries through injection molding. This significantly reduces production costs for large-scale manufacturing.

Advantages and Disadvantages of Plastic Spiral Gears

Advantages of Plastic Spiral Gears

Lightweight Structure: Plastic material reduces the overall mass and inertia of a mechanical system. This contributes to faster response and higher efficiency.

Quiet Operation: The combination of spiral tooth geometry and the inherent damping properties of engineering plastics results in smoother and quieter motion.

Corrosion resistance: Plastic spiral gears also offer excellent corrosion and chemical resistance, making them suitable for use in humid, wet, or chemically exposed environments where metal gears would corrode over time.

Cost Saving: Plastics are cost-effective and easy to mold, allowing for high-volume manufacturing and complex geometries that would be expensive to machine from metal.

Disadvantages of Plastic Spiral Gears

- Lower Load Bearing: Under high torque or continuous high-speed conditions, plastics can deform or wear faster than metals.

- Thermal Sensitivity: Elevated temperatures can cause expansion, softening, or warping of the material, leading to dimensional instability and changes in backlash.

- Dimensional Instability: Plastic materials also tend to have lower stiffness and strength, which may result in deflection under load. In addition, some polymers are prone to moisture absorption, which can alter mechanical properties over time.

Design Considerations for Plastic Spiral Gears

Material Selection

Select polymers with adequate mechanical properties. Nylon 66 (PA66) provides wear resistance and toughness. Polyoxymethylene (POM) offers low friction and dimensional stability. Add 15-30% glass or carbon fiber to increase modulus by 2-3 times. Avoid unreinforced plastics for loads above 5 Nm.

Helix Angle Optimization

Limit helix angle to 15°-25° in plastic spiral gears. Higher angles increase axial thrust, which plastics handle poorly due to low stiffness. Lower angles simplify mold flow and reduce warpage.

Tooth Geometry Adjustments

Use standard 20° pressure angle. Apply profile modifications:

- Root fillet radius: 0.3-0.5 module to reduce stress concentration.

- Tip relief: 0.01-0.03 mm to accommodate deflection under load.

- Crown thickness is slightly increased to compensate for thermal expansion.

Backlash and Tolerance

Set operating backlash at 0.15-0.30 mm, higher than metal (0.05-0.10 mm). Account for:

- Molding shrinkage: 0.5-2.0% depending on material.

- Thermal expansion: 80-120 × 10⁻⁶/°C.

- Test at maximum service temperature.

Manufacturing Process

Injection molding remains primary for spiral gear manufacturer production. Gate location at gear center minimizes weld lines. Post-mold annealing at 80-100°C for 2 hours reduces residual stress. CNC machining of metal hubs ensures shaft alignment.

Spiral Gear Applications

Automotive Industry: Differential systems, steering mechanisms, power seats, and mirror adjustment systems.

Industrial Machinery: Actuators, gearboxes, conveyors, and automation equipment.

Aerospace and Defense: Control actuators, gear-driven assemblies, and navigation systems.

Robotics and Automation: Robotic arms, grippers, and servo systems.

Consumer Electronics: Printers, cameras, small motors, and smart devices.

Medical Devices: Diagnostic equipment, imaging systems, and precision pumps.

Marine and Energy Equipment: Propulsion systems, pumps, and gear-driven generators.

Conclusion

Spiral gears, particularly plastic spiral gears, expand options for efficient transmission. They differ from spiral bevel gears in geometry and use. Common processing methods for plastics include injection molding, with CNC finishing for precision. Spiral gear manufacturers and spiral bevel gear manufacturers continue to refine these components. Contact Flexiparts to explore custom solutions.