Custom plastic strips are widely used components in industrial, commercial, and engineering applications. Their simple geometry, stable performance, and material versatility make them suitable for sealing, protection, spacing, and wear resistance. From standard profiles to custom-designed solutions, plastic strips support many functional requirements across different industries.

What Are Plastic Strips?

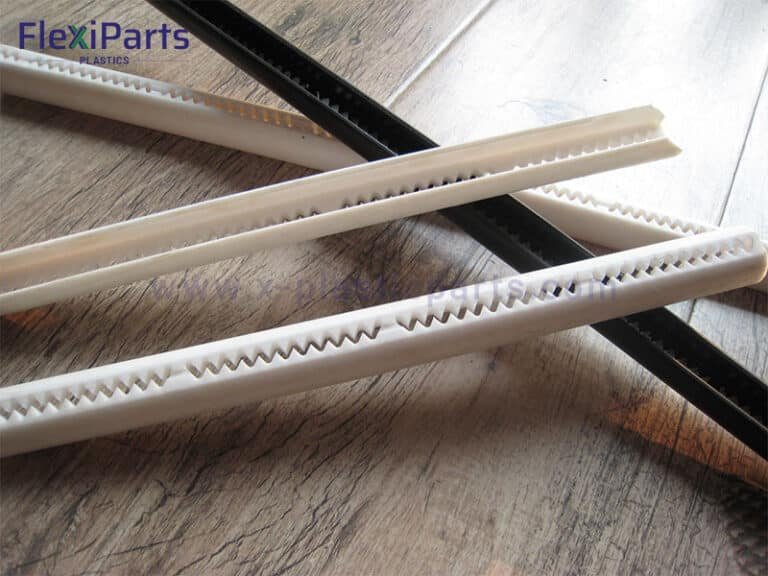

Plastic strips consist of thermoplastic materials formed into linear profiles. These profiles can be flat, rounded, or shaped with channels. Common dimensions range from a few millimeters in width to several centimeters, with lengths cut to order.

Advantages of Plastic Strips

Plastic strips offer several practical advantages in industrial environments. They are lightweight, corrosion-resistant, and generally unaffected by moisture. Many plastic materials provide good chemical resistance and electrical insulation, making them suitable for diverse operating conditions.

In addition, plastic strips can be produced with tight dimensional consistency and customized cross-sections, which simplifies integration into existing assemblies. Compared to metal alternatives, plastic strips often reduce noise, friction, and maintenance requirements.

Common Materials Used for Plastic Strips

Material selection is critical to the performance of plastic strips. Different polymers offer distinct mechanical, thermal, and chemical properties.

ABS

ABS strips are flat plastic profiles made from Acrylonitrile Butadiene Styrene (ABS), known for their strength, impact resistance, and dimensional stability. They are commonly used in structural support, edging, spacers, guides, and protective applications across industrial and commercial equipment.

PVC

PVC appears in both rigid and flexible forms. Flexible PVC works well for seals due to its compression recovery. Rigid PVC provides good dimensional stability and impact resistance for edging. This material resists weather and many chemicals.

HDPE and LDPE

High-density polyethylene (HDPE) and low-density polyethylene (LDPE) are known for their moisture resistance and chemical stability. These materials have low-friction surfaces and good impact resistance. Plastic strips made from HDPE or LDPE are often used in protective liners, guides, and light-duty wear applications.

UHMW-PE

Ultra-high-molecular-weight polyethylene is widely used for plastic wear strips. It offers an extremely low coefficient of friction and excellent abrasion resistance. UHMW plastic wear strips are commonly installed in conveyor systems, sliding rails, and material handling equipment where continuous contact and movement occur.

Nylon

Nylon plastic strips provide higher mechanical strength and stiffness. They perform well under moderate loads and exhibit good wear resistance. Nylon strips are often used in applications requiring structural support, alignment, or repeated mechanical contact.

PTFE

PTFE plastic strips are selected for applications involving high temperatures, chemical exposure, or low-friction requirements. PTFE offers excellent thermal stability and chemical inertness, making it suitable for sealing and sliding applications in demanding environments.

PP

PP handles chemical environments and repeated bending without fatigue failure. It maintains strength at elevated temperatures compared to some other plastics.

Elastomer-Based Plastics

Thermoplastic elastomers such as TPU and TPE are used when flexibility and elasticity are required. These plastic strips are commonly applied for vibration isolation, impact absorption, and sealing. Their ability to deform and recover makes them suitable for uneven surfaces or dynamic assemblies.

Types of Plastic Strips by Function

Plastic strips fall into categories based on their primary role.

Sealing Plastic Strips

Sealing plastic strips are designed to prevent the ingress of dust, moisture, air, or fluids. They are often produced from flexible PVC, TPE, or rubber-based materials. These strips are commonly used in enclosures, doors, panels, and equipment housings.

Protective Plastic Strips

Protective plastic strips are used to shield edges, surfaces, and components from impact or abrasion. They help reduce damage during operation, handling, or transportation. Edge trims and surface protection strips are typical examples.

Wear Plastic Strips

Plastic wear strips are specifically designed to reduce friction and resist abrasion between moving parts. Materials such as UHMW-PE and nylon are commonly selected for these applications. Plastic wear strips are widely used in conveyor systems, guide rails, and sliding interfaces to extend equipment service life.

Insulating Plastic Strips

Some plastic strips serve as electrical or thermal insulation components. Their non-conductive properties make them suitable for electrical panels, cable management systems, and industrial enclosures.

Decorative and Finishing Plastic Strips

In addition to functional roles, plastic strips are also used for finishing and visual consistency. These strips are often applied to cover joints, edges, or transitions in consumer products and architectural elements.

Industrial Applications of Plastic Strips

Plastic strips are used across a wide range of industries due to their adaptability and consistent performance.

Manufacturing and Material Handling: Conveyor guides, plastic wear strips, chain guides, belt supports.

Automotive and Construction: Weather seals, door trims, window channels, protective edging strips.

Agriculture, Mining, and Heavy Machinery: Scraper blades, chute liners, dock bumpers, abrasion-resistant strips.

Food/Beverage and Packaging: Hygienic guides, seals, conveyor wear strips (FDA-compliant materials).

Other Applications: Strip curtains (warehouse temperature control), marine fenders, wastewater liners, retail display trims.

Custom Plastic Strip Manufacturing Options

As a direct manufacturer, we produce custom plastic strips based on your drawings, samples, or technical specifications, supporting both small and large volume projects.

Extrusion Production

Extrusion is the most efficient method for plastic strips with consistent cross-sections and long production runs. We design custom dies according to your required dimensions and control thickness and width to ensure stable quality. Strips can be supplied in continuous lengths or cut to your specified size for easy integration into your assembly.

CNC Machining

For low-volume orders, prototypes, or more complex geometries, CNC machining provides greater flexibility without mold investment. We machine engineering plastics such as Nylon, UHMW, and POM, achieving tight tolerances suitable for precision applications.

Material & Design Support

Material selection is based on your operating temperature, load conditions, friction requirements, and chemical exposure. We also review your design to ensure manufacturability and proper fit within your final assembly.

Secondary Processing

Additional services such as drilling, slotting, adhesive backing, surface treatment, and color customization are available. Parts can be delivered ready for installation, reducing extra processing on your side.

Conclusion

Custom plastic strips provide functional solutions in sealing, protection, and abrasion resistance. Their range of materials and manufacturing options supports diverse industrial needs. Working with experienced manufacturers ensures that custom plastic strips or rubber strips are designed and produced to deliver consistent performance, reliability, and long-term value.