Vacuum cups are components used in industrial applications for handling materials. They provide a method for lifting and moving objects without direct mechanical contact.

What is a Vacuum Cup?

A vacuum cup, often referred to as a vacuum suction cup, is a device used in various industrial applications for holding and moving objects without the need for mechanical fasteners or manual labor. These cups use the principle of vacuum suction to create a stable grip on an object, enabling it to be lifted, transported, or positioned with precision. The versatility and simplicity of vacuum cups have made them indispensable in many sectors, particularly in automation and material handling.

Vacuum Cup Work Principle

A vacuum cup works by generating a vacuum, or negative pressure, between the cup and the surface of an object. When the vacuum is created, atmospheric pressure pushes the cup against the object, creating an effective seal. The force holding the object is calculated using the formula F = P × A, where F is the holding force, P is the pressure difference, and A is the effective area of the cup. This force holds the object securely in place, allowing it to be moved without direct contact or the use of additional fixtures.

The primary function of a vacuum cup is to lift and move objects without the need for direct physical contact, which can be especially useful for delicate or irregularly shaped items that may be damaged by traditional handling methods. The suction created by the vacuum cup provides a reliable means of lifting, even for heavy or complex-shaped objects, as long as there is a good seal.

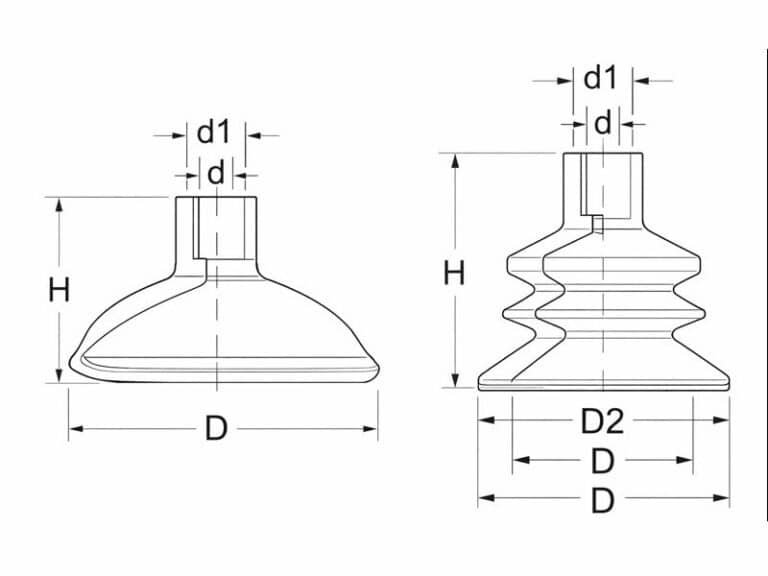

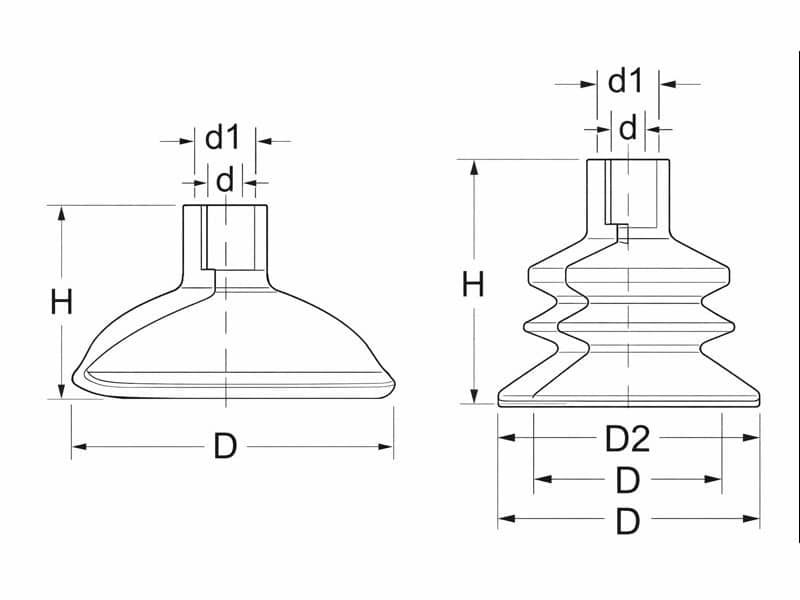

Components of a Vacuum Cup

The construction of a vacuum cup is fairly straightforward. The main components include the cup itself, a sealing element, and a connection to a vacuum source.

Vacuum Cup Body: Typically made from materials like rubber, silicone, or plastic, the cup body is designed to create the surface contact that forms the vacuum. It is usually flexible, allowing it to conform to the shape of the object being lifted.

Sealing Element: The sealing element, often a rubber or soft material, is crucial for ensuring that no air can escape when the vacuum is applied. The seal prevents leakage, which could otherwise reduce the lifting capacity of the vacuum cup.

Vacuum Connection: The vacuum cup is connected to a vacuum system, usually through a hose or tube. This system creates the necessary suction by removing air from within the cup. The vacuum pressure is maintained while the object is being held, enabling secure transportation.

Key Parameters of the Vacuum Cup

- Diameter, which ranges from 4 mm to over 900 mm, affects the area and thus the force.

- Hardness is measured in Shore A, typically 40 to 70, influencing flexibility and durability.

- Volume or internal capacity impacts evacuation time; smaller volumes allow faster cycle times.

- Other parameters are the operating temperature range and chemical resistance, which vary by material.

Main Applications of Vacuum Cups

Vacuum cups are used in a wide range of industries, particularly those that rely on automation and precise material handling.

Industrial Automation: Vacuum cups are commonly used in robotic arms and automated production lines for handling parts and products.

Packaging and Assembly: In the packaging and assembly industries, vacuum cups are used for picking and placing items such as bottles, boxes, and components.

Glass and Electronics Manufacturing: Vacuum cups are often used in the handling of delicate items such as glass panels and electronic components.

Material Handling: In warehouses and logistics centers, vacuum cups are used to move heavy or awkwardly shaped items, such as metal sheets or machinery parts.

Metalworking: Vacuum cups handle sheets in stamping or laser cutting processes. They manage oily or textured surfaces effectively with appropriate lip designs.

Material Selection and Design Suggestions

Materials for vacuum cups are chosen based on environmental conditions and object properties.

- Nitrile rubber (NBR) is common, offering oil resistance and durability in temperatures from -10°C to +80°C. It suits metal handling.

- Silicone (VMQ) provides a wider temperature range, -40°C to +200°C, and is food-grade compliant. It is used in high-heat or sanitary applications like baking or pharmaceuticals.

- Polyurethane(PU) offers high wear resistance for abrasive surfaces, operating from -20°C to +80°C. It is ideal for rough materials like wood or recycled items.

- Fluorocarbon (FKM) resists chemicals and high temperatures up to +200°C, applied in harsh environments.

Design Considerations and Tips

When designing a vacuum cup for a particular application, several factors should be considered:

Size and Shape: The size of the vacuum cup should match the size of the object being lifted. Larger cups may be necessary for heavier or bulkier items, while smaller cups may be suitable for delicate components.

Sealing and Vacuum Strength: The strength of the vacuum is critical in determining how well the cup can hold the object. It’s important to select a vacuum cup with a vacuum system that can provide enough suction for the task.

Material Compatibility: Consider the material of the object being lifted and choose a vacuum cup material that will provide a strong seal without damaging the surface.

Environmental Factors: The operating environment, such as temperature, humidity, and exposure to chemicals, should also be taken into account when choosing the material and design of the vacuum cup.

Conclusion

Vacuum cups serve as essential tools in industrial handling. They operate on pressure differences to provide secure attachment. Proper selection ensures operational efficiency and safety. Advances in materials and designs continue to expand their use in automation.