In the world of automotive performance, many modifications are designed to enhance the efficiency and power of an engine. One such modification is the underdrive pulley. By altering the way engine accessories operate, the underdrive pulley aims to reduce parasitic power losses and improve engine output.

What Are Underdrive Pulleys?

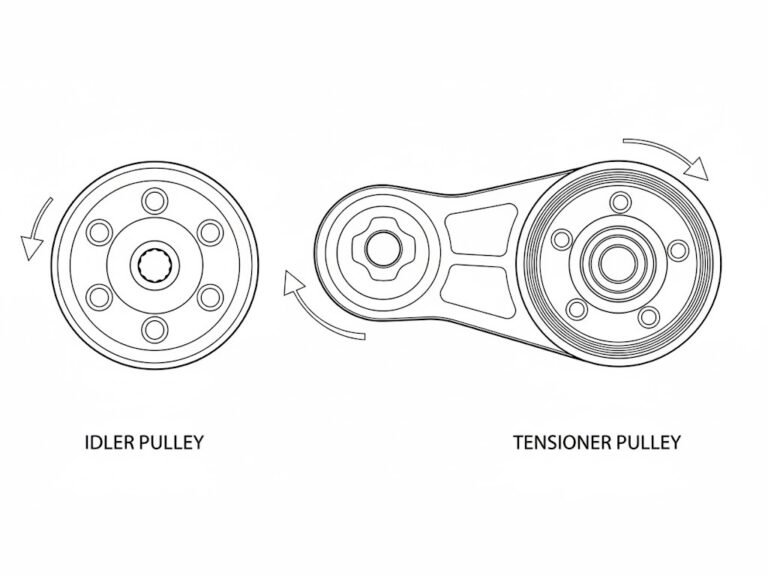

An underdrive pulley is a smaller, lightweight pulley used to replace the stock pulleys on an engine’s accessories, such as the alternator, water pump, and power steering pump. The purpose of this component is to reduce the speed at which these accessories operate by using a pulley that is smaller than the original. By slowing down the rotation of non-essential components, more power is diverted to the drivetrain, which can lead to increased performance and better overall engine efficiency.

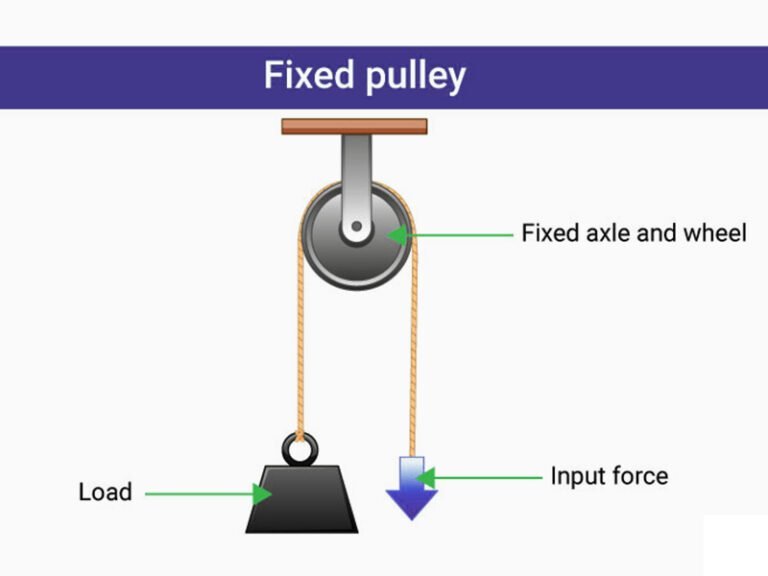

The underdrive pulley works by altering the rotational speed of the accessories driven by the engine belt. Because the pulley is smaller in diameter, the engine’s accessories rotate more slowly, requiring less power from the engine to maintain their function. This reduction in load on the engine translates into more power being available for acceleration, and often results in slight improvements in fuel efficiency as well.

Key Differences Between Underdrive and Standard Pulleys

A standard pulley drives engine accessories at full engine RPM, while an underdrive pulley reduces their speed. This lowers engine load, decreases power consumption, and can improve overall performance, especially in high-performance or modified vehicles.

How Do Underdrive Pulleys Work?

An underdrive pulley is slightly smaller than the standard pulley, which slows down engine accessories like the alternator and water pump. This means the engine doesn’t have to work as hard to drive them, freeing up more power for the wheels. The result is better acceleration, quicker throttle response, and improved overall performance, though some accessories, like the alternator, may produce slightly less output at idle.

The Pros and Cons of Custom Underdrive Pulleys

Advantages of Underdrive Pulleys

- Increased Engine Performance: The underdrive pulley reduces engine load, allowing more power to reach the drivetrain and improving acceleration and responsiveness.

- Improved Fuel Efficiency: With less power needed for accessories, the engine becomes more efficient, which can lead to small improvements in fuel economy.

- Better Overall Engine Efficiency: By reducing unnecessary energy consumption, the underdrive pulley improves engine efficiency, especially in performance applications.

Disadvantages of Underdrive Pulleys

- Slower Accessory Functioning: Slowing down the alternator and other accessories can affect their performance, especially at lower engine speeds.

- Potential for Overheating: With a slower water pump, cooling may be less effective, especially under high-performance conditions.

- Compatibility Issues: Not all vehicles are suited for underdrive pulleys, and some may experience issues with charging or cooling, making it important to ensure compatibility with your engine.

Industries and Applications Using Custom Underdrive Pulleys

Custom underdrive pulleys are commonly used in industries that require high performance and engine optimization. Motorsports, for example, often rely on these components to increase engine efficiency and reduce unnecessary power consumption. Racing vehicles, where every small performance enhancement counts, can benefit greatly from the installation of an underdrive pulley.

Additionally, enthusiasts involved in custom car builds, tuning, and engine modifications often seek out underdrive pulleys to enhance their vehicles’ performance. These custom pulleys can be made to fit specific engine configurations and offer tailored solutions for performance tuning.

Partnering with a Professional Custom Pulley Manufacturer

Underdrive pulleys can boost engine performance, improve fuel efficiency, and optimize overall engine operation. However, achieving these benefits requires precision manufacturing to ensure critical engine components are not compromised. That’s where Flexiparts comes in: as a professional custom pulley manufacturer, we produce underdrive pulleys according to your designs, guaranteeing high-quality, precise fabrication and a perfect fit. Working with us lets you bring your pulley designs to life safely and reliably.