Silicone gaskets are widely used for leak-proof sealing in high-temperature, food-grade, and outdoor applications. In this guide, we’ll cover silicone gasket properties, common types (solid, sponge, foam, molded), key applications, and how to choose the right hardness, thickness, and manufacturing method for your project.

What is a Silicone Gasket?

A silicone gasket is a sealing component made from silicone, a synthetic siloxane-based polymer (mSiO₂·nH₂O), prized for its flexibility, durability, and resistance to extreme temperatures (-60°C to +250°C), chemicals, and aging. These non-toxic, often food-grade gaskets create airtight or watertight seals, preventing leaks, vibrations, or environmental ingress in applications from heavy machinery to household appliances. For instance, in a coffee maker, a gasket silicone rubber ensures your morning brew stays drip-free, while its safety makes it ideal for medical or food processing settings.

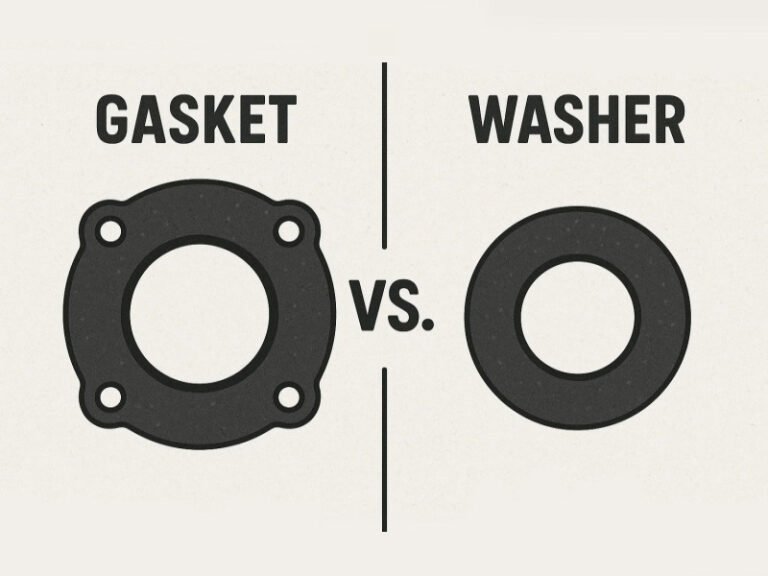

Silicone vs. Rubber: What’s the Difference?

Choosing between a silicone gasket and a rubber gasket silicone alternative can be pivotal for your project’s success. To make an informed decision, it’s essential to understand how these materials stack up in terms of composition, performance, and cost. The table below provides a clear comparison to highlight their differences, helping you select the right material for your sealing needs.

| Property | Silicone Gasket | Rubber Gasket |

|---|---|---|

| Composition | Synthetic siloxane-based polymer (mSiO₂·nH₂O) | Natural (latex) or synthetic (e.g., nitrile, neoprene) |

| Temperature Range | -60°C to +250°C, excels in extreme conditions | -20°C to +100°C, limited in high/low extremes |

| Chemical Resistance | Broad resistance to acids, alkalis, oils, solvents | Vulnerable to oils, strong acids/alkalis; may swell |

| Elasticity | Stable under prolonged stress, 10A–70A durometer | Better initial elasticity, less stable long-term |

| Cost | Higher due to complex manufacturing | More affordable, simpler production |

| Durability | Superior resistance to aging, ozone, weathering | Prone to degradation over time |

Benefits of Silicone Gaskets

Silicone gaskets offer numerous benefits that make them highly suitable for a wide range of applications across industries:

- Extreme Environment Sealing: Their ability to withstand scorching heat or cold ensures leak-free performance in automotive or aerospace applications.

- Non-Toxic and Safe: Food-grade silicone gaskets are perfect for sealing food processing equipment or medical devices, ensuring no contamination.

- Long Lifespan: Resistance to UV, ozone, and aging means fewer replacements, saving costs over time.

- Versatility: From electronics to construction, gasket silicone rubber adapts to diverse industries with ease.

- Low Maintenance: Non-stick and easy to clean, these gaskets simplify upkeep in demanding settings.

- Flame Retardant: Many silicone gaskets are flame-resistant, suitable for applications where exposure to high temperatures or fire risk exists.

- Customizability: Silicone gaskets can be manufactured in various hardness levels, thicknesses, colors, and shapes to precisely fit application requirements, enhancing sealing effectiveness.

- Electrical Insulation and Conductivity Options: Silicone gaskets provide excellent electrical insulation, protecting electronic components, and some formulations offer EMI shielding capabilities.

Common Types and Forms of Silicone Gaskets

Silicone gaskets can be classified in multiple ways. To avoid confusion, the following sections organize gasket types by material structure first, followed by manufacturing methods and functional performance.

By Material Structure (Primary Classification)

Solid Silicone Gaskets

- Dense, non-porous silicone rubber

- Shore A hardness: typically 20–70

- Require ~15–25% compression

- Best for: water sealing, pressure sealing, long-term durability

Sponge Silicone Gaskets

- Cellular structure with air pockets

- Open-cell or closed-cell

- Require higher compression (30–50%)

- Best for: uneven surfaces, vibration damping, dust sealing

Silicone Foam Gaskets

- Microcellular structure with skin surface

- Lower closure force than the sponge

- Excellent rebound and weather resistance

- Best for: water spray sealing, enclosure sealing

By Manufacturing Process

Die-Cut Silicone Gaskets

- Cut from silicone sheets

- Cost-effective for flat designs and high volumes

Injection Molded Silicone Gaskets

- Complex 3D geometry

- Tight tolerances and integrated features

Compression Molded Silicone Gaskets

- Suitable for medium-volume custom shapes

- Lower tooling cost than injection molding

By Functional Performance

Conductive Silicone Gaskets

- EMI / RFI shielding

- Filled with silver, nickel, or carbon

FDA-Grade Silicone Gaskets

- Food-contact and medical compliant

- Odorless, tasteless, non-toxic

Fluorosilicone Gaskets

- Resistant to fuels, oils, and solvents

- Used in aerospace and automotive fuel systems

Fire-Retardant / UL-Rated Silicone Gaskets

- For electrical enclosures and safety systems

Applications of Silicone Gaskets

The versatility of silicone gaskets shines across industries, from automotive to electronics — and especially in demanding applications like the medical silicone gasket.

- Food and Medical: FDA-compliant gasket silicone rubber seals food processing equipment (e.g., blenders) and medical devices (e.g., ventilators), ensuring safety and sterility.

- Automotive: From engine seals to cooling systems, silicone gaskets withstand high temperatures and chemical exposure in vehicles.

- Electronics: Used for waterproofing, insulation, or EMI shielding, these gaskets protect smartphones, laptops, and solar panels.

- Construction: Silicone gaskets seal joints in high-temperature or humid environments, like HVAC systems or building facades.

- Household: Think of anti-slip mats, coasters, or meal pads—silicone gaskets enhance everyday products with durability and safety.

Silicone Gasket Selection Checklist

- Temperature range: -60°C to +250°C (typical)

- Hardness (Shore A): 20A / 40A / 60A

- Thickness: 0.5mm / 1mm / 2mm / 3mm+

- Sealing pressure: low compression vs high clamping force

- Food contact: FDA / LFGB

- Production volume: prototype vs mass production

- Process: die-cut vs compression molded vs injection molded

Custom Silicone Gasket Manufacturing Considerations

At FlexiParts, custom silicone gaskets are engineered with a manufacturing-first approach to ensure reliable sealing in real-world conditions.

Material Selection

We recommend the right silicone grade and durometer (typically 10A–70A) based on temperature, pressure, and application requirements, including FDA-compliant options for food and medical use.

Design & Tolerance Review

Compression ratio, thickness, and sealing surfaces are reviewed before production to prevent leakage and premature failure.

Manufacturing Process

Die cutting and waterjet cutting are used for flat or low-volume gaskets, while injection or compression molding supports complex shapes and stable mass production.

Application Matching

Gaskets are designed to withstand specific temperatures, chemicals, and environmental exposure in their intended operating conditions.

Compliance & Cost Control

We support FDA and RoHS requirements and help balance performance, durability, and cost from prototype to production.

If you have a drawing, sample, or sealing requirements, FlexiParts can help you select the best silicone gasket material and process for a stable, leak-free result.