Rubber bellows are indispensable components in many industrial, automotive, and mechanical systems. Their unique accordion-like design allows them to protect moving parts, absorb vibrations, and accommodate mechanical movement while maintaining a tight seal against contaminants such as dust, moisture, and chemicals. This article delves into the various types of rubber bellows, explores the concept of custom rubber bellows, and highlights the benefits of flexible rubber bellows in diverse applications.

What Are Rubber Bellows?

Rubber bellows are flexible, hollow, and expandable components made primarily from elastomeric materials. Often resembling flexible tubes, they act as seals, expansion joints, or protective covers, safeguarding equipment from dust, moisture, and chemical exposure. Their characteristic corrugated or convoluted structure enables them to stretch, compress, and bend without compromising their sealing capabilities.

Custom rubber bellows provide tailored solutions for specific system requirements. They ensure compatibility with unique designs and perform reliably in harsh environments, including extreme temperatures and aggressive chemicals.

Materials Used in Rubber Bellows

The performance of rubber bellows depends heavily on the materials chosen, which must align with the application’s environmental and operational demands. Common materials include:

- Natural Rubber: Offers excellent flexibility, tear resistance, and abrasion resistance, but limited heat and chemical resistance. Ideal for general industrial and automotive uses.

- Neoprene: Good weathering and moderate oil resistance, often used in HVAC ducting.

- Nitrile Rubber: Known for outstanding oil and fuel resistance, commonly used in automotive fuel systems and hydraulic applications.

- EPDM: Excellent resistance to weathering, ozone, UV, and chemicals, making it suitable for outdoor HVAC and chemical processing environments.

- Silicone: Provides high flexibility and heat resistance, used in aerospace and medical devices.

- Viton: Withstands aggressive chemicals and high temperatures, ideal for oil and gas applications.

Types of Rubber Bellows

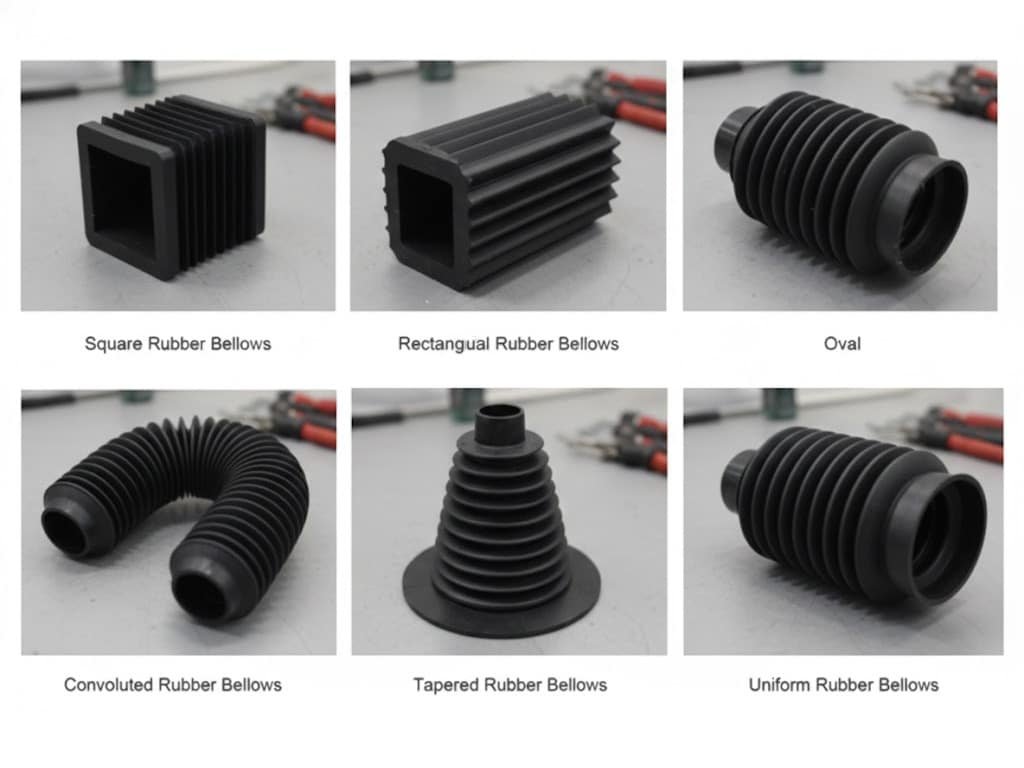

Rubber bellows can be custom-designed in various shapes, materials, and functional styles to meet specific application requirements. This section presents classifications of rubber bellows by shape and function, illustrating the diverse possibilities for tailored solutions.

Classification by Shape and Construction

Cylindrical Bellows

These have a straight, uniform diameter throughout their length. Cylindrical bellows are widely used to protect shafts, spindles, or rods from dust, moisture, and mechanical damage.

Conical Bellows

Featuring a tapered profile, conical bellows allow for a reduction in diameter on one end. This design is ideal when space constraints require a compact form or when components of different sizes must be connected.

Rolling (Cuff) Bellows

These ultra-flexible bellows have thin walls that roll or fold over themselves during movement. They provide low-friction extension and retraction, making them suitable for precision applications.

Accordion Bellows

Designed with deep convolutions, accordion bellows can compress and expand significantly. They are commonly used as protective covers or as flexible connections in equipment that requires frequent motion.

Classification by Function

Protective Bellows

These bellows are primarily used to shield sensitive components from dust, dirt, moisture, and other contaminants. They help maintain clean operating conditions and prolong the service life of machinery.

Expansion Joints

Designed to absorb thermal expansion, contraction, and vibration, expansion joints prevent damage caused by movement or misalignment in piping systems and ductwork.

Flexible Connectors

These bellows serve as vibration isolators and compensate for slight misalignments between connected equipment. They help reduce noise and mechanical stress.

Sealing Bellows

Sealing bellows create airtight or watertight barriers around moving parts. They are commonly used in valves, actuators, and automotive assemblies to prevent fluid or gas leakage.

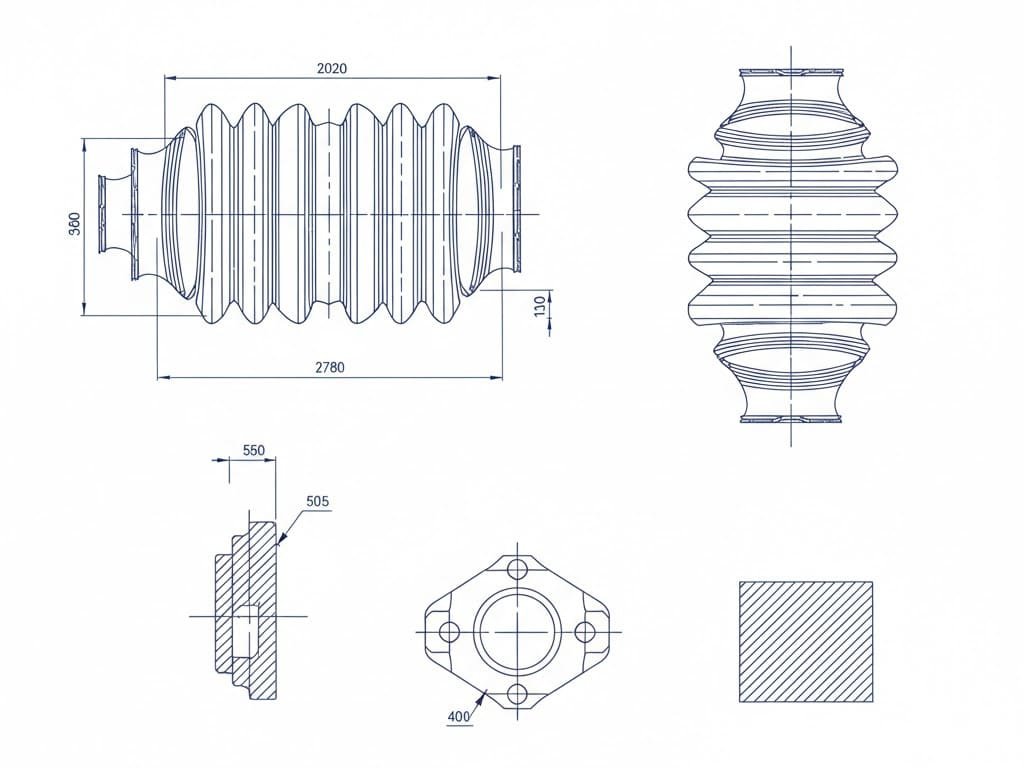

Custom Rubber Moulded Bellows

Custom rubber moulded bellows are tailored to your exact specifications, ensuring a perfect fit and reliable protection. With customizable materials and properties, they withstand heat, chemicals, and harsh environments effectively.

Advantages of Rubber Bellows

Flexible rubber bellows stand out for their ability to accommodate complex movements and harsh environments. Their key advantages include:

Flexibility: Flexible rubber bellows accommodate axial, lateral, and angular movements, reducing stress on connected components.

Noise and Vibration Reduction: By absorbing mechanical vibrations, they help reduce noise and wear in machinery and vehicles.

Excellent Sealing: Their design prevents ingress of dust, moisture, and contaminants, protecting sensitive mechanical parts.

Ease of Installation and Maintenance: Flexible bellows simplify assembly and reduce maintenance costs by protecting joints and seals.

Durability: Resistant to abrasion, chemicals, heat, and ozone, depending on material choice, ensuring long service life.

Versatility: Available in various types of rubber bellows, they suit a wide range of industries and applications.

Applications of Rubber Bellows

Rubber bellows find applications across a broad spectrum of industries:

Automotive:

Protect steering racks, CV joints, ball joints, and exhaust systems from dirt, moisture, and mechanical stress.

HVAC Systems:

Provide weather-resistant seals in ducting and expansion joints.

Industrial Machinery:

Seal and protect moving parts in hydraulic and pneumatic cylinders, pumps, and valves.

Aerospace:

Silicone and Viton bellows withstand extreme temperatures and chemical exposure in aircraft systems.

Chemical Processing:

Seal pumps and pipelines, preventing leaks of corrosive fluids.

Pharmaceuticals:

Ensure sterile environments by protecting equipment from contaminants.

Oil & Gas:

Custom rubber bellows made of Viton withstand harsh chemicals and high temperatures in refineries.

Design Considerations for Rubber Bellows

Designing effective rubber bellows requires careful consideration of several factors to ensure performance and durability:

Environment: Consider the operating environment, including temperature, chemicals, and exposure to UV radiation. If the bellows will come into contact with chemicals, it’s essential to ensure that the chosen material is chemically compatible and won’t degrade or react adversely.

Size and Shape: Consider the size and shape of the bellow to ensure it fits within your system without interference.

Convolution Shape and Number: The number and depth of convolutions impact flexibility and pressure resistance. More convolutions enhance flexibility but may reduce strength.

Movement: Determine the range and frequency of movement the bellow will experience; speed can also be a factor to consider.

Sealing Material: Rubber is a preferred material for sealing applications thanks to its superior flexibility, resilience, and leak-proof performance.

Wall Thickness: Thicker walls improve durability but reduce flexibility, requiring a balance based on application needs.

Pressure and Temperature Ratings: Ensure bellows can withstand operational conditions, such as high-pressure hydraulic systems.

Conclusion About Rubber Moulded Bellows

Rubber bellows are versatile components essential for protecting and enhancing the performance of numerous mechanical and industrial systems. Understanding the types of rubber bellows, materials selection enables to selection or creation of the ideal solution for their specific needs. Flexiparts supplies various types and materials for rubber molding customization services. Welcome to contact us and get a rubber bellows solution.