Oval suction cups are specialized components in vacuum handling systems. These cups feature an elongated shape that differs from traditional round designs, allowing them to address specific challenges in material handling. In industrial settings, where workpieces vary in form and surface characteristics, selecting the appropriate suction cup type is essential for maintaining efficiency and reliability.

What Are Oval Suction Cups?

Oval suction cups are vacuum-gripping components with an elliptical contact surface rather than a circular one. They are designed specifically for handling long, narrow workpieces. Compared with standard round designs, oval vacuum suction cups provide a longer sealing line in one direction. This allows the suction force to be distributed more evenly along the length of the part. As a result, they are commonly used in applications involving profiles, strips, frames, stamped metal parts, and automotive components with elongated geometries.

Why Use Oval Suction Cups?

Oval suction cups offer several functional advantages for handling long, narrow workpieces.

Increase The Effective Contact Surface

The extended shape increases the effective contact surface along the length of the object, which results in higher holding forces under the same vacuum level. This configuration reduces the risk of slippage or detachment during movement, particularly in horizontal transfers or rotations.

Longer Sealing Lip

Compared to round suction cups, oval designs provide better stability on elongated items, as the longer sealing lip distributes force more evenly and minimizes deformation of thin or flexible materials.

Improve Friction

They also improve friction between the cup and workpiece, enhancing grip on smooth, oiled, or slightly textured surfaces. In automated processes, this leads to fewer handling errors, reduced cycle interruptions, and lower potential for workpiece damage.

How Oval Suction Cups Work?

The operating principle of oval suction cups is based on standard vacuum technology, but the force distribution differs significantly from round designs. When a vacuum is applied, the sealing lip conforms to the workpiece surface, creating a pressure differential that generates a holding force.

Because of the oval geometry, this force is spread along the long axis of the cup. This reduces localized stress and minimizes the risk of deformation or air leakage at the edges. In dynamic applications, such as robotic pick-and-place systems, this distribution helps maintain grip stability even when lateral or shear forces are present.

In practice, oval suction cups are often oriented so that their long axis aligns with the dominant load direction. This orientation further enhances resistance to slipping and improves control during handling.

Common Types of Oval Suction Cups

Oval suction cups are available in several structural variants, each suited to different operating conditions.

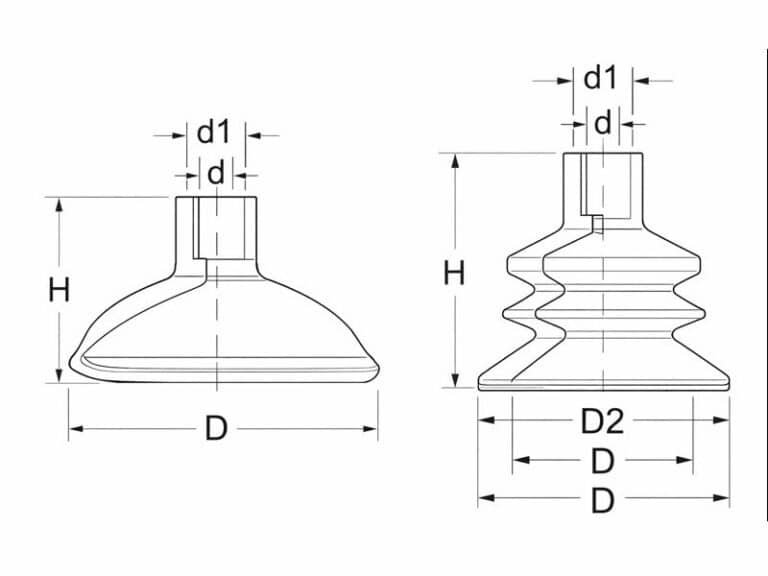

Oval Flat Suction Cups

These have a flat sealing lip and no folds. The flat design gives a large contact area along the long axis and a small internal volume, allowing fast air evacuation and quick gripping. They work best on even or slightly curved surfaces, such as flat metal sheets, glass panels, wooden boards, or profiles. They provide excellent positioning accuracy, good resistance to side forces, and very little bending during use.

Oval Bellows Suction Cups

These include one or more bellows folds. The bellows add flexibility, vertical movement, and height compensation, so the cup can adjust to uneven heights, tilted surfaces, or slight curves. They handle higher side forces well and perform reliably on curved, angled, or irregular long items like formed sheet metal, thin parts, or packaging.

Oval Concave Suction Cups

These have a curved (concave) inner shape that fits convex or outwardly rounded surfaces. The concave design improves sealing on domed, rounded, or contoured long objects, such as car body panels, fuel tanks, or shaped metal parts. It increases contact quality, boosts holding force on non-flat shapes, and reduces air leaks on curved surfaces with small radii. They are commonly used in automotive processes like de-stacking, framing, or assembly, where parts have clear curves.

Materials and Customization Options for Oval Suction Cups

Material selection for oval suction cups depends on environmental conditions, workpiece properties, and operational demands. Common elastomers include:

- NBR (Nitrile Rubber) is commonly used for oval suction cups in general industrial environments. It offers a good balance of wear resistance, oil resistance, elasticity, and cost efficiency.

- Silicone provides wide temperature tolerance (from low to over 200°C in some grades) and is often chosen for food, pharmaceutical, or high-heat applications.

- Polyurethane (PU) is chosen for high-cycle applications where abrasion resistance and long service life are critical.

Oval Suction Cups Customization

In addition to material selection, oval suction cups can be customized in several ways.

Additional options include hardness variations (e.g., 45–60 Shore), anti-static formulations, PWIS-free (paint-wetting impairment-substances-free) versions, or FDA-compliant grades. Customization extends to dimensions, lip profiles (e.g., special slots for oiled sheets), reinforced bases, or integrated supports.

How to Choose the Right Oval Suction Cups?

Selecting the appropriate oval suction cup material requires a systematic evaluation of operating conditions rather than reliance on size alone.

- Analyzing the Workpiece Geometry: Analyzing the workpiece geometry, including length, width, and available gripping zones. The suction cup should cover as much usable surface as possible without interfering with edges or holes.

- Consider the Surface Condition: Smooth, flat surfaces allow for firmer sealing, while textured or oily surfaces may require softer materials or reinforced lips.

- Handling Direction and Motion: Applications with high acceleration, vertical lifting, or lateral movement benefit from oval suction cups oriented along the main load direction.

- Consider Environmental: The factors such as temperature, contamination, and cycle frequency should also influence material choice.

- Compatible: Ensure that the selected oval vacuum suction cups are compatible with the available vacuum level and airflow capacity of the system.

Applications of Oval Suction Cups

Oval suction cups are used across multiple industries where elongated parts must be handled reliably.

- Automotive manufacturing: handling body panels, structural reinforcements, trim components, and stamped metal parts

- Metal processing: transferring profiles, bars, and cut-to-length sheets

- Automation and assembly: positioning frames, rails, and narrow housings

- Packaging and logistics: gripping long cartons, trays, or packaged products

Conclusion

Oval suction cups provide a targeted solution for gripping long and narrow workpieces, delivering consistent holding force, stability, and adaptability. Customized oval vacuum cups will help to match different shapes and size workpiece gripping. Flexiparts provides custom solutions for suction cups. Welcome to contact us and get a solution for your project.