How pulley works? Why can the movement of the heavy loads be done with reduced effort? Pulleys play a crucial role in various industrial settings. Understanding how pulleys work provides insight into their practical value. This article explores how pulley systems work, focusing on their mechanics and applications in industrial settings.

What is a Pulley?

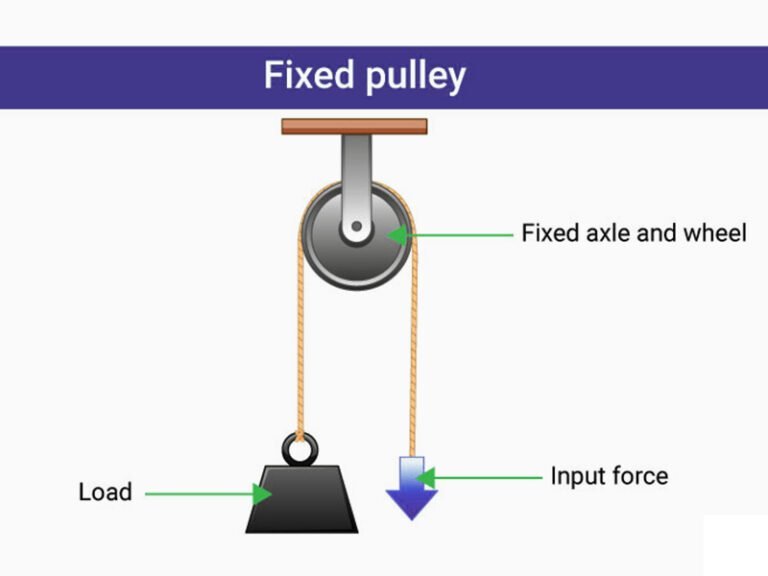

At its core, a pulley is a simple machine composed of a wheel with a groove around its edge, through which a rope, cable, or belt runs. The wheel rotates on an axle or shaft, and the rope transmits force along the system. Pulleys can be constructed from various materials depending on their use. Common materials include durable metals like steel or aluminum for heavy-duty industrial pulleys, and plastic pulleys for lighter loads or specialized purposes, which are often made from materials like nylon or acetal. The choice of material impacts the pulley’s strength, wear resistance, and suitability for different applications.

How Pulley Works?

A pulley changes the direction of an applied force, making lifting tasks easier. This redirection is a fundamental way pulleys work to assist physical effort. The rope runs through the pulley’s groove, aligning the force to suit the task.

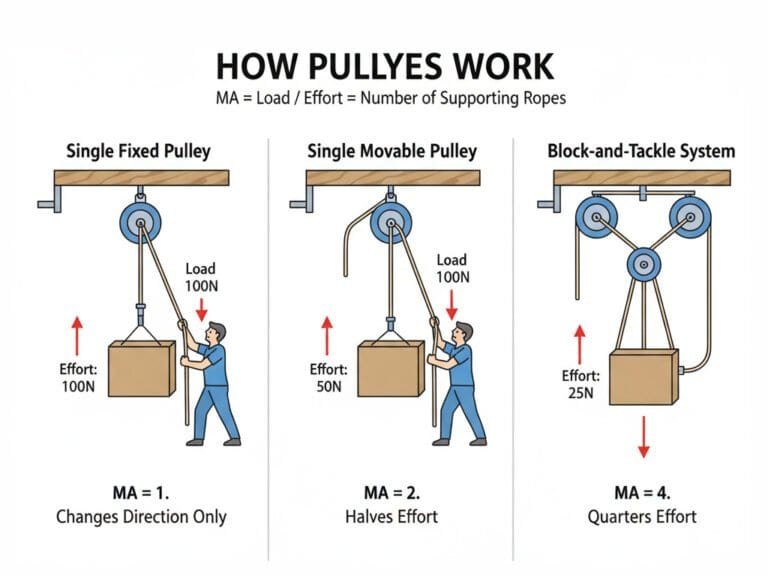

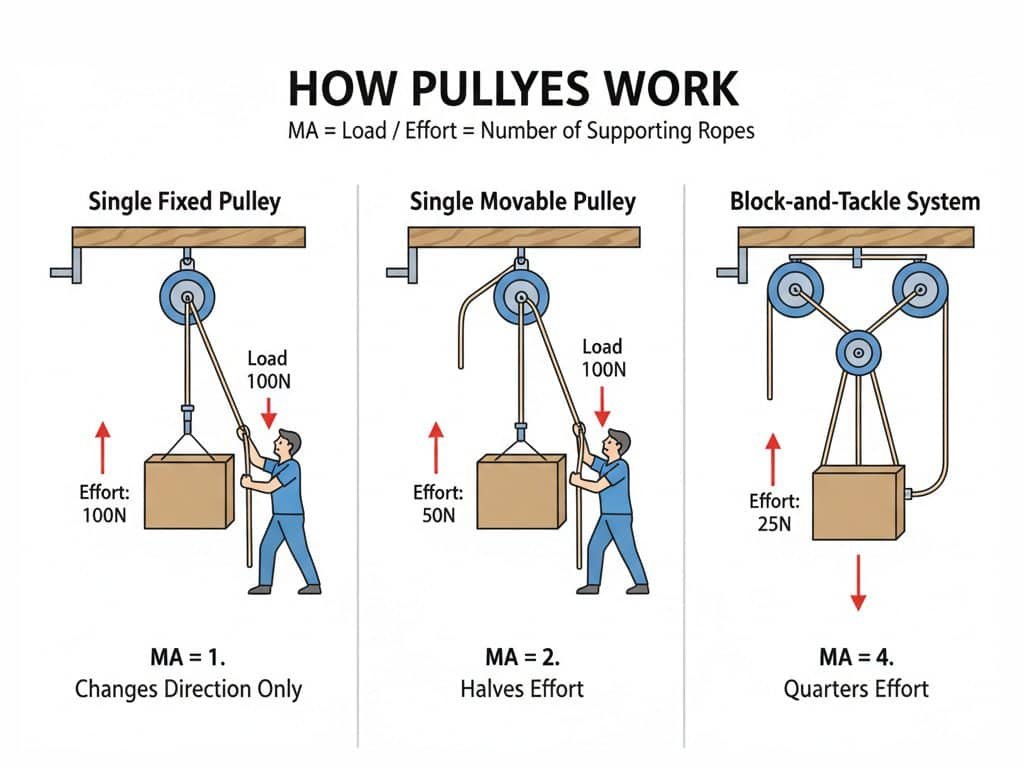

Pulleys can also reduce the force needed to move heavy loads. A movable pulley, unlike a fixed one, moves with the load, distributing weight across multiple rope segments. This creates a mechanical advantage (MA), defined as the ratio of the load (output force) to the effort (input force). For a single fixed pulley, MA equals 1, meaning it changes direction without reducing effort. A movable pulley, however, might have an MA of 2, halving the required force. This trade-off between force and distance is central to how pulleys work.

Compound pulley systems, often called block-and-tackle, combine multiple pulleys to increase mechanical advantage. The load is shared among many rope sections, so the force you apply is divided. If four rope segments support a load, the MA is 4, meaning the effort is one-fourth the load’s weight. The formula is simple: MA = Load / Effort or, in compound systems, MA equals the number of supporting ropes. More pulleys mean correspondingly higher mechanical advantage, reducing effort further, though practical limits like friction and rope stretch apply.

Applications in Industry

Pulleys are widely used across various industries to facilitate the lifting and moving of heavy objects with greater ease and efficiency.

- In manufacturing, they drive conveyor belts that transport materials and products.

- Construction sites use pulley systems in cranes and hoists to lift heavy loads safely.

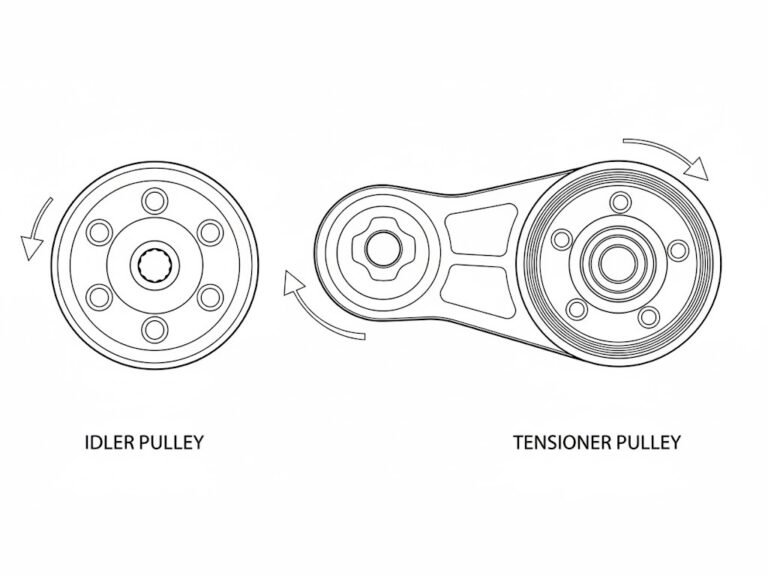

- Automotive engines depend on pulleys for timing belts and accessory drives.

- In agriculture and mining, pulleys help operate machinery under tough conditions.

- Food processing and packaging machines use pulleys to maintain smooth, continuous operation.

Conclusion

Pulleys are straightforward yet effective tools. A single pulley redirects force. By combining multiple pulleys into pulley systems like the block and tackle, the mechanical advantage increases significantly, offering excellent force reduction at the cost of pulling extra rope length. Flexiparts offers customized plastic pulleys based on the customer’s requirements. Contact and get a tailored custom solution.