In many vehicles, there are many issues about vibrations through the steering wheel or floor, higher levels of engine noise in the cabin, and faster wear on related components. These issues frequently originate from worn or mismatched engine mount bushings. Standard replacements can address basic needs, but they may not suit modified vehicles, performance applications, or specific requirements. This has led to growing interest in custom engine mount bushing solutions that address specific performance and durability requirements.

What Are Engine Mount Bushings?

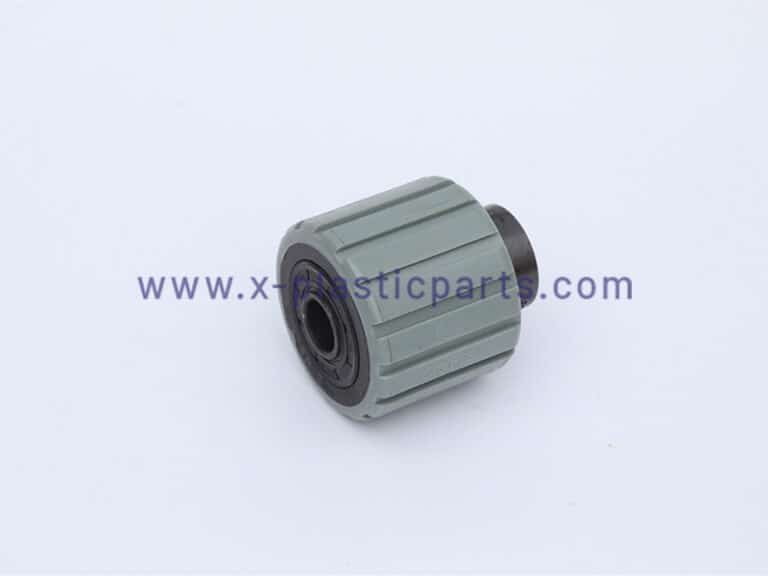

Engine mount bushings are elastomer-based components installed between the engine assembly and the vehicle frame or subframe. Their primary role is to support the engine while isolating vibration and limiting the transmission of noise to the chassis.

The most commonly used materials for engine mount bushings include natural rubber, synthetic rubber compounds, rubber, and polyurethane. Different rubber formulations can be tailored to meet specific hardness and environmental resistance requirements.

Properly designed engine mount bushings contribute directly to vehicle comfort and reliability. They help reduce vibration transmitted from the engine to the cabin, lower noise levels, and protect the engine and mounting hardware from excessive mechanical stress. Over time, well-matched bushings also reduce the likelihood of secondary failures in hoses, brackets, and adjacent assemblies.

Common Issues and Selection Guidelines

When engine mount bushings are not correctly selected, several issues may occur. Bushings that are too soft may allow excessive engine movement, leading to misalignment or contact with surrounding components. On the other hand, bushings that are too hard can transmit vibration directly into the vehicle body, increasing noise and reducing ride comfort.

Dimensional inaccuracies are another common problem. Even small deviations in diameter or length can result in uneven load distribution, accelerated wear, or installation difficulties. In rubber–metal bushings, poor bonding quality can cause early separation between the rubber and metal insert, significantly shortening service life.

How to Choose the Right Engine Mount Bushings for Your Vehicle

Selecting suitable engine mount bushings requires a clear understanding of the vehicle’s operating conditions. Vehicle type is an important factor. Daily commuting favors comfort-focused options, while performance or track use prioritizes control. Off-road or heavy-load applications need durable materials.

Engine weight, torque output, and mounting geometry must also be considered. Vehicles operating under heavy loads, frequent stop-and-go conditions, or elevated temperatures place higher demands on bushing materials and design.

Factors That Affect Bushing Performance

Several technical factors directly influence the performance of engine mount bushings.

Material hardness, typically measured by durometer, determines how much vibration is absorbed versus how much structural support is provided. Selecting an appropriate hardness range is critical to achieving stable performance.

Dimensions and tolerances affect both fit and durability. Tight dimensional control ensures proper installation and consistent load transfer. Shape and internal structure, such as solid versus voided designs, influence stiffness and vibration isolation characteristics.

Metal inserts or sleeves play a key role in rubber–metal bushings. They improve resistance to deformation, provide secure mounting points, and enhance overall durability. Finally, the quality of rubber-to-metal bonding is essential for long-term reliability, particularly in applications exposed to cyclic loads and environmental stress.

Standard vs. Custom Engine Mount Bushings

Standard engine mount bushings provide exact fitment, balanced NVH characteristics, and lower cost. They suit unmodified vehicles well but wear faster under increased stress and offer limited options for upgrades. Standard sizes may not fit perfectly in modified or rare vehicles, leading to installation issues or suboptimal performance.

Custom engine mount bushings are developed to match specific performance targets. By adjusting material composition, hardness, dimensions, and internal structure, custom bushings can better accommodate unique vibration frequencies, load conditions, and installation constraints.

Flexiparts in Fully Custom Engine Mount Bushing Solutions

Flexiparts produces engine mount bushings without inventory restrictions, enabling production to meet customer requirements.

Customizable aspects include material selection (rubber or polyurethane) with precise durometer ratings, full dimensional control (inner/outer diameters, height, offsets), shape variations (solid, voided, or complex geometries), and metal sleeve specifications.

Production supports submission of samples for replication, detailed engineering drawings, or reverse engineering from existing parts. This suits low-volume needs, prototypes, or one-off applications.

Conclusion

Engine mount bushings contribute to vehicle comfort, handling, and component longevity. When the standard bushings cannot meet the requirements, a custom engine mount bushing will be a good choice. Custom engine mount bushings offer a practical solution by combining material properties, geometry, and structure with actual application demands. Flexiparts supplies full custom bushing production. Welcome to provide samples or drawings and get a production solution.