In electrical conduit systems, small components often make a big difference. While conduits protect cables along their route, the points where wires enter or exit a conduit are especially vulnerable. Sharp edges, vibration, and long-term movement can all damage conductor insulation if not properly managed.

Conduit bushings are designed to solve this exact problem. Installed at conduit terminations, they protect wires, support code compliance, and improve long-term system reliability across residential, commercial, and industrial applications.

What is a Conduit Bushing?

A conduit bushing fits over the end of electrical conduits such as EMT, PVC, or rigid metal types. Its primary function prevents wire insulation damage from burrs or rough edges on conduit openings. This protection maintains wire integrity and supports safe current flow in electrical installations.

Difference from Other Conduit Fittings

Conduit bushings differ from couplings, which join two conduit sections end-to-end. Unlike connectors that secure conduits to boxes or enclosures, bushings focus solely on edge protection without providing structural attachment. They require no threading or locking mechanisms, distinguishing them from locknuts or set screws used in other fittings. This design allows quick snap-on or push-fit installation.

Why Conduit Bushings Are Important?

Conduit bushings play a critical role in protecting electrical conductors at conduit entry and exit points. By covering sharp edges and threads, they prevent insulation damage during wire pulling, operation, or movement. This protection helps reduce electrical faults, extends cable service life, and improves overall system reliability. In addition, conduit bushings support compliance with electrical codes and inspection requirements, especially in installations exposed to vibration, thermal expansion, or long-term wear.

Types of Conduit Bushings

Conduit bushings come in several types based on function and material.

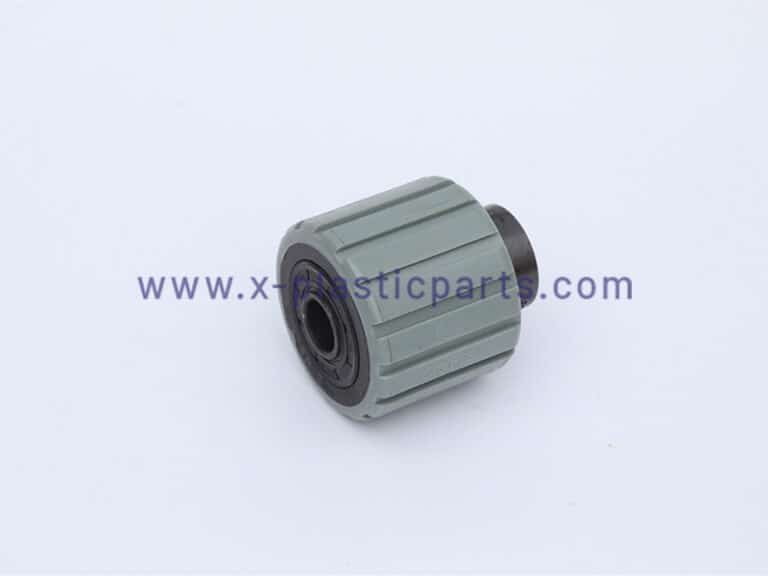

Plastic Conduit Bushings

Plastic conduit bushings use nylon or PVC materials. They offer non-conductive properties and corrosion resistance. These suit residential wiring and light commercial applications where weight and cost matter. Plastic bushings for electrical use snap onto conduit ends easily for quick installs.

Metal Conduit Bushings

Metal conduit bushings consist of steel or zinc construction. They handle high mechanical stress and vibration in industrial settings. These provide robust edge protection for heavy-duty conduits in machinery or outdoor equipment. Threaded designs secure firmly to metal conduits.

Insulated Conduit Bushings

Insulated conduit bushings feature a metal body with a plastic liner. The liner adds electrical isolation to prevent shorts in high-voltage systems. UL-listed versions meet NEC requirements for wet locations or high-load circuits. They combine durability with enhanced safety.

Grounding Bushings

Grounding bushings include a grounding screw or lug. These connect the conduit to a grounding conductor. They are used with metal conduits for safety.

Sealing Bushings

Sealing bushings feature seals like O-rings or compounds. These prevent moisture, dust, or gases from entering. They suit outdoor or wet locations.

Common Applications of Conduit Bushings

Conduit bushings are used in various electrical installations to protect conductors at conduit terminations. Here are some typical applications:

- Entry into electrical panels and cabinets

- Junction boxes and pull boxes

- Residential wiring with PVC conduits

- Industrial facilities requiring grounding

- Lighting or utility connections.

- Utility and underground projects

Standard vs. Custom Conduit Bushings

Standard conduit bushings fit common trade sizes and meet UL and NEC specifications for most projects. They match off-the-shelf EMT, PVC, or rigid conduits. Availability in bulk keeps costs low for standard installations.

Custom conduit bushings address specialized requirements. Manufacturers produce them for non-standard diameters, exotic materials like high-temperature polymers, or integrated sealing features. These suits harsh environments, such as chemical plants needing corrosion-resistant variants or OEM assemblies for unique equipment.

Conclusion

While standard conduit bushings meet most general requirements, many projects demand custom solutions due to non-standard conduit sizes, special materials, or challenging environments.

Flexiparts is a professional manufacturer of custom conduit bushings, offering made-to-spec solutions in materials, dimensions, and design optimization. Whether for standard installations or specialized OEM applications, Flexiparts supports reliable, application-driven conduit bushing solutions. Contact us to discuss your project requirements.