Custom Rubber Washer

Custom Molded Rubber Washers Manufacturer

When standard washers fail because they leak, wear out, or don’t fit, Flexiparts steps in. We are a custom rubber washer factory and handle everything in-house, making washers to your exact size, hardness, and material requirements for reliable, fully customized sealing, protection, and vibration control.

Getting a custom rubber washer solution is simple — send us your drawing or sample, and we’ll handle mold/die design, quoting, and production. Contact us anytime via our website, email, or phone to start your project.

Rubber Washer Solutions Built to Your Needs

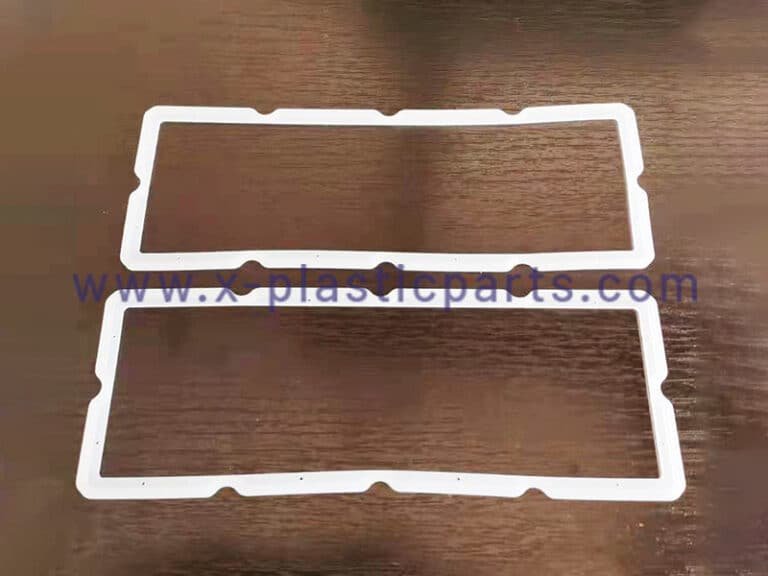

*Please note: The molded rubber parts shown below are not in stock — these parts were Flexiparts Plastics customized for other customers.

LET’S START A NEW CUSTOM RUBBER PARTS

Rubber Washers Design Suggestions

When customizing rubber washers, pay attention to sealing performance and compression set by selecting the right material and thickness. Consider the inner diameter (ID), outer diameter (OD), and thickness (T) to ensure a perfect fit. Choose materials that resist the media (oils, chemicals, water) and the operating environment (UV, temperature extremes), and ensure tight tolerances for reliable, long-term sealing.

Rubber Washer Manufacturing Methods

- Compression Molding

- Injection Molding

- Overmolding

These processes are suitable for producing high-precision molded washers, thick rubber spacers, and custom rubber washers with consistent quality.

Material

Our custom rubber washers are available in a variety of high-performance elastomers:

- Ethylene Propylene Diene Monomer (EPDM)

- Nitrile (NBR)

- Neoprene (CR)

- Silicone (MVQ)

- Fluoroelastomer (FKM)

- Natural Rubber (NR)

Benefit

- Create tight seals against fluid, gas, and dust leaks.

- Act as effective spacers or cushions to prevent metal-to-metal contact.

- Dampen vibrations and reduce noise in assemblies.

- Durable and resistant to wear, chemicals, and temperature extremes.

- Flexible sizes and thicknesses for any sealing or spacing requirement.

- Custom colors or specific hardness (durometer) available.

Application

- Plumbing and Piping Systems: For sealing joints and connections.

- Automotive: In engines, fluid systems, and electrical assemblies.

- Electrical Enclosures: Sealing against moisture and dust.

- HVAC Equipment: Reducing vibration and sealing air ducts.

- Appliances and Consumer Goods: For sealing and cushioning.

Related FAQs of Rubber Washers and Gasket

A rubber washer provides spacing or cushioning, while a gasket seals between surfaces. Custom solutions can combine both functions.

Silicone (MVQ) and FKM resist high temperatures and maintain flexibility. We can supply washers in these materials.

EPDM or UV-stabilized NBR offer excellent weather and UV resistance. Custom hardness and materials ensure long-term durability.

Yes, we produce fully custom rubber washers to any size, thickness, or shape required.

Typically 3–5 years if kept cool, dry, and away from sunlight and ozone. Material choice can extend shelf life.

What Our Customers Say