In pulley systems, there are different types of pulleys to meet specific needs. Among them, the fixed pulley is one of the most frequently chosen options because of its straightforward design and reliable performance.

What is a Fixed Pulley?

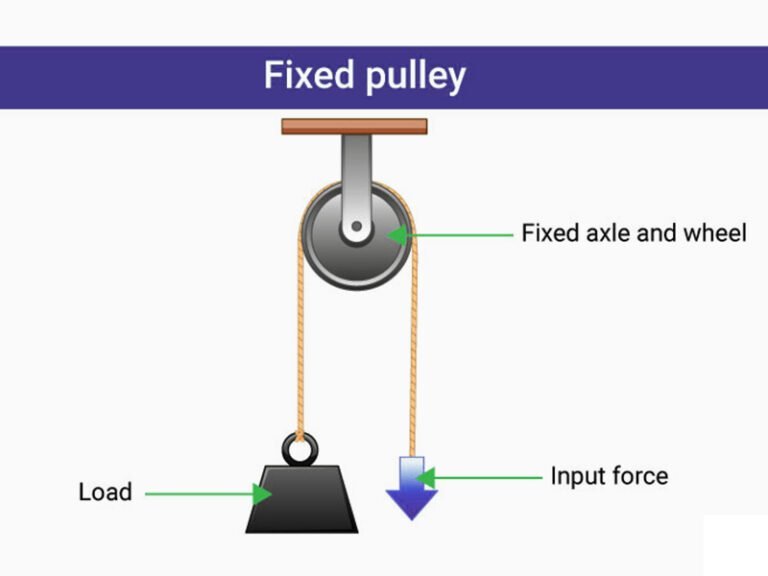

A fixed pulley is a simple machine consisting of a wheel with a grooved rim and an axle. The wheel is mounted on a stationary support, usually a beam, ceiling, or frame, so the pulley itself does not move up or down with the load. A rope, cable, or belt runs in the groove around the wheel. When force is applied to one end of the rope, the load attached to the other end moves in the opposite direction. The primary function of a fixed pulley is to change the direction of the applied force, not to reduce the amount of force required.

Common Materials Used for Fixed Pulleys

Fixed pulleys are made from a variety of materials to suit different applications. Common options include steel for high strength and heavy loads, stainless steel for corrosion resistance, aluminum alloy for lightweight designs, and engineering plastics like nylon or POM for smooth, low-friction operation. Some pulleys also use composite materials to combine durability with reduced noise and weight.

How Does a Fixed Pulley Work?

The operating principle of a fixed pulley is based on tension equilibrium in the rope. When you pull down on the free end of the rope, the tension created is transmitted equally throughout the rope length (assuming negligible friction). This tension acts upward on the load side of the rope. Because the pulley is fixed in place, the wheel simply rotates on its axle while the support structure absorbs the total force.

The mechanical advantage of a single fixed pulley is 1:1. This means the output force equals the input force. The fixed pulley only changes direction. Bearings or bushings in the axle reduce friction and allow smooth rotation even under substantial loads.

Advantages of Fixed Pulleys

Fixed pulleys offer several practical benefits that explain their widespread use:

- Simple Design: Fixed pulleys have a straightforward structure with minimal moving parts, making them easy to manufacture and install.

- Minimal Maintenance: Due to their simple construction, fixed pulleys require less maintenance and are less prone to mechanical failure.

- Cost-Effective: Compared to more complex pulley systems, fixed pulleys are generally more affordable while still providing functional utility.

- Ease of Operation: By changing the direction of applied force, fixed pulleys make lifting operations more practical and user-friendly.

- Versatility: Fixed pulleys can be adapted for various settings, from industrial lifting tasks to residential or small-scale mechanical setups.

Common Applications of Fixed Pulleys

Fixed pulleys are used across a wide range of industries and applications due to their simple yet effective function.

- Construction and Material Handling: Cranes, hoists, and lifting systems.

- Residential and Commercial Settings: Flagpoles, window blinds, and curtain systems.

- Water Wells and Bucket Lifting Systems: Fixed pulleys help lift water buckets in wells or small-scale fluid handling setups.

- Fitness Equipment: Gym machines use fixed pulleys to guide cables and adjust the direction of applied force in resistance training.

- Industrial Machinery: Fixed pulleys serve as guiding components for belts or cables in conveyor systems, assembly lines, and other equipment requiring controlled motion.

Customized Fixed Pulley Solutions from Flexiparts

Although the market offers numerous standard fixed pulleys in common sizes and load ratings, real-world equipment, varying load requirements, and specific installation environments often demand more precise specifications. Standard products may not fully match unique shaft diameters, groove profiles, material requirements, or extreme operating conditions.

Flexiparts provides professional pulley customization services. We can manufacture pulleys with exact dimensions, selected materials, specialized surface treatments, and integrated high-performance bearings.