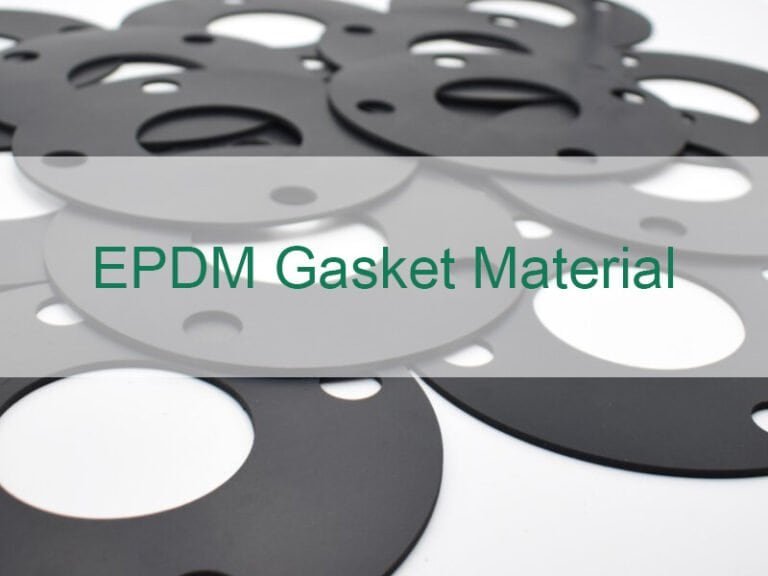

EPDM gasket material (Ethylene Propylene Diene Monomer) is one of the most widely used rubber materials for gaskets and seals. Known for its excellent weather resistance, elasticity, and chemical stability, EPDM performs reliably in outdoor environments, water and steam systems, and many industrial applications. In this guide, we’ll cover the key properties, types, grades, and typical uses of EPDM gasket material.

Key Properties of EPDM Gasket Material

EPDM gaskets are made from ethylene and propylene copolymers and are known for their outstanding elasticity. Their long molecular chains allow EPDM to remain flexible at low temperatures while also maintaining stability in higher-temperature conditions.

- Excellent elasticity and flexibility for reliable sealing performance

- Strong mechanical properties, with tensile strength typically around 7 to 21 MPa

- Resistance to abrasion and aging, supporting long service life

- Good resistance to acids and alkalis, making it suitable for many industrial environments

- Excellent resistance to oxidation, UV light, and ozone, ideal for outdoor use

- Suitable for steam and hot-water sealing in many applications

Types of EPDM Gasket Material

EPDM rubber gasket material is available in different structures to match sealing requirements such as pressure, compression recovery, and environmental exposure.

1. Solid EPDM

Solid EPDM is dense and compression-resistant. It is commonly used when a gasket must maintain sealing integrity under higher pressure or repeated compression.

2. Sponge / Foam EPDM

Sponge EPDM is lighter and provides better cushioning and conformability, which is useful for low-force sealing, vibration isolation, or gap filling.

Common foam structures include:

- Closed-cell EPDM: more water-resistant, suitable for better sealing against moisture

- Semi-closed or open-cell EPDM: highly flexible and compressible, often used for cushioning or vibration control

![]()

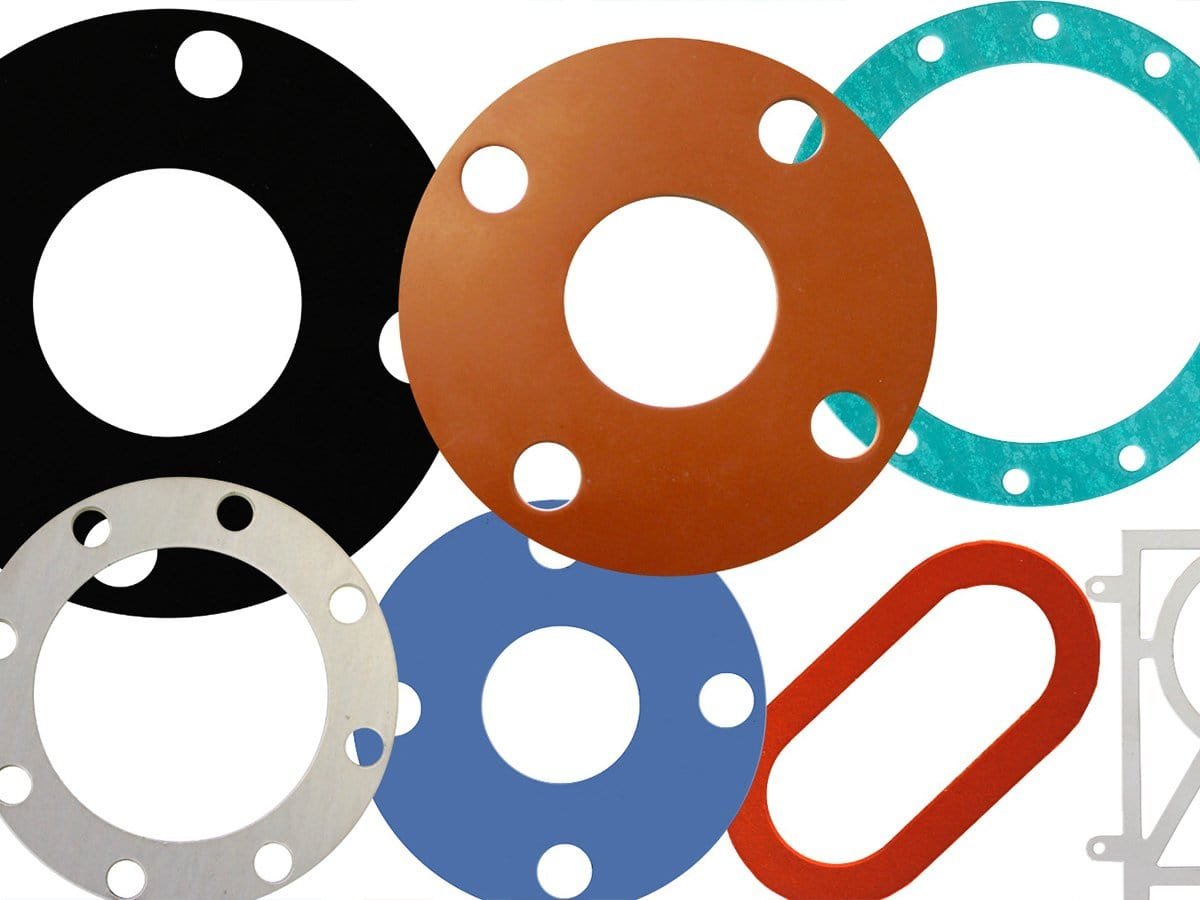

Grades of EPDM Gasket Material

Different EPDM grades offer different performance levels. Selecting the right grade helps ensure the gasket works reliably under the required temperature, chemical exposure, and compliance standards.

- Commercial Grade EPDM: Cost-effective and suitable for general sealing in low-pressure applications.

- Peroxide-Cured EPDM: Offers improved heat resistance and better chemical stability for more demanding conditions.

- Sulfur-Cured EPDM: A standard option for general-purpose sealing requirements.

- FDA-Approved EPDM: Non-toxic EPDM designed for food-contact and pharmaceutical applications (often available in white).

- UL 94 Flame-Retardant EPDM: Designed to meet fire safety requirements for applications where flame resistance is needed.

Common Applications of EPDM Gaskets

EPDM gasket material is widely used because it maintains flexibility and sealing integrity even in harsh environments. EPDM is especially popular in applications where outdoor exposure, ozone/UV resistance, and long-term durability are key requirements.

- Automotive: door and window seals, weatherstripping, hoses, O-rings

- Construction: roofing membranes, window/door sealing, HVAC systems

- Industrial: water and steam pipelines, chemical processing equipment, vibration isolation systems

- Electrical: enclosure seals, cable protection, sealing components

- Marine: boat sealing, deck fittings, hoses exposed to weather and water

Gasket EPDM Material in Other Sealing Components

EPDM rubber gasket material can also be used to manufacture various sealing and protection parts, especially where long-term weather resistance and flexible sealing are required, such as:

- EPDM O-rings

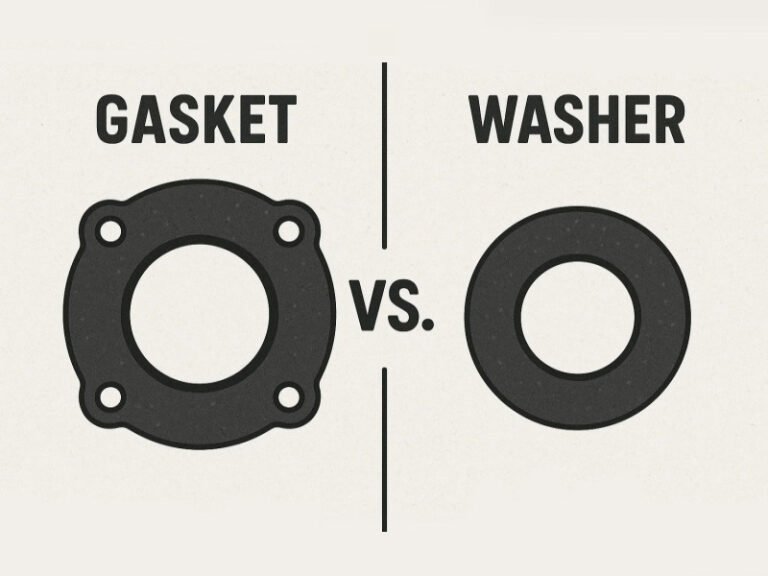

- EPDM washers and spacers

- Custom molded EPDM rubber parts

- EPDM seals and pads for cushioning and vibration absorption

These components allow designers to apply EPDM’s sealing performance across different mechanical and industrial assemblies.

Conclusion

Gasket EPDM material is a reliable solution for sealing applications that require excellent weather resistance, flexibility, and chemical stability. By choosing the right EPDM type (solid or sponge) and selecting the appropriate grade (commercial, peroxide-cured, FDA, flame-retardant, etc.), manufacturers can achieve long-lasting sealing performance across a wide range of industries.

If you need EPDM gasket made to your drawing or application requirements, custom EPDM gaskets can be produced in different shapes, thicknesses, hardness levels, and structures to match your sealing needs.