Material handling suction cups are an efficient tool in industrial processes where items need to be lifted, moved, or positioned without direct contact. These components are used in automation systems, assembly lines, and packaging operations across sectors such as manufacturing, logistics, and food processing. The effectiveness of material handling suction cups depends on their ability to create a secure vacuum seal with various surfaces, which ensures safe and efficient transport of goods. Without proper selection, issues like slippage or damage to materials can occur.

Key Factors Affecting Suction Cup Performance

The performance of material handling suction cups depends on several factors. Understanding these factors will help you select the best suction cup material and design for your application.

Surface Characteristics

The surface texture of the material can vary from smooth and flat to rough or uneven, and each type requires a different approach to ensure an effective grip. For instance, flat suction cups work best on smooth, non-porous surfaces, such as metal or plastic. However, when dealing with irregular or curved surfaces, a bellows-style suction cup, which offers more flexibility, may be necessary to compensate for the surface’s unevenness. Rough or porous surfaces, such as wood or cardboard, need cups with flexible edges to adapt and prevent air leaks.

Weight and Size of Load

The weight and size of the load affect the choice. Heavier items demand larger diameter material handling suction cups or multiple units arranged in arrays to distribute the force evenly. A safety factor, often set at 4:1 or higher, is applied to account for dynamic movements and potential vacuum loss.

Environmental Conditions

Environmental factors, such as temperature, exposure to chemicals, and the presence of oils or grease, can also affect suction cup performance. For example, suction cups used in high-temperature environments need to be made from materials that can withstand heat without degrading, such as silicone or Viton. Similarly, exposure to chemicals or oils may require specialized materials like nitrile or polyurethane, which are resistant to such substances.

Speed and Type of Movement

The speed and type of movement in the handling process matter. High-speed robotic arms generate shear forces that can dislodge cups, so material handling suction cups with reinforced structures are necessary for such applications.

Vacuum System Compatibility

Vacuum system compatibility is essential. The pump’s flow rate and pressure level must match the cup’s design to achieve quick attachment and release cycles.

How to Choose the Right Suction Cup Materials?

Material handling suction cups are available in a variety of materials, each offering specific advantages depending on the application. Understanding the properties of each material can help you choose the best option for your needs.

Nitrile Rubber (NBR)

Nitrile rubber is a durable and cost-effective material often used for applications where oil resistance and abrasion resistance are essential. NBR suction cups are commonly used in industrial environments, where they perform well on rougher surfaces and offer good wear resistance. NBR typically has a hardness range of 50-65 Shore A and operates effectively between -20°C and 100°C. They are a solid choice for applications involving metal or plastic parts that are heavy and subject to frequent handling.

Silicone

Silicone is another widely used suction cup material for material handling suction cups. It offers flexibility and a broad temperature tolerance from -60°C to 220°C, which is ideal for applications involving heated glass or frozen products. Silicone’s non-marking property makes it appropriate for delicate surfaces like electronics or painted items. Food-grade versions comply with FDA standards, supporting use in packaging lines for consumables.

Polyurethane (PU)

Polyurethane (PU) serves as a durable suction cup material in high-wear environments. It excels in resistance to tearing and abrasion, fitting material handling suction cups for automated systems or for lifting materials with rougher surfaces. PU can handle temperatures up to 90°C and is often chosen for longevity in repetitive cycles, though it comes at a higher cost than NBR.

Fluorocarbon Rubber

Fluorocarbon rubber, such as Viton or FKM, is selected as a suction cup material for challenging conditions. It resists chemicals and high temperatures up to 250°C, making it suitable for material handling suction cups in chemical processing or heat-treated metal transport. This material is less flexible but provides long-term stability in aggressive settings.

Polyvinyl Chloride (PVC)

Polyvinyl Chloride (PVC) acts as an economical suction cup material alternative. It offers moderate durability and is used in material handling suction cups for general-purpose tasks with low demands, such as handling cardboard boxes. PVC performs in ambient temperatures but lacks the specialized resistance of other options.

Suction Cup Types for Material Handling Applications

Material handling suction cups come in various types, each designed to accommodate specific material surfaces and characteristics. Proper matching improves grip and prevents failures.

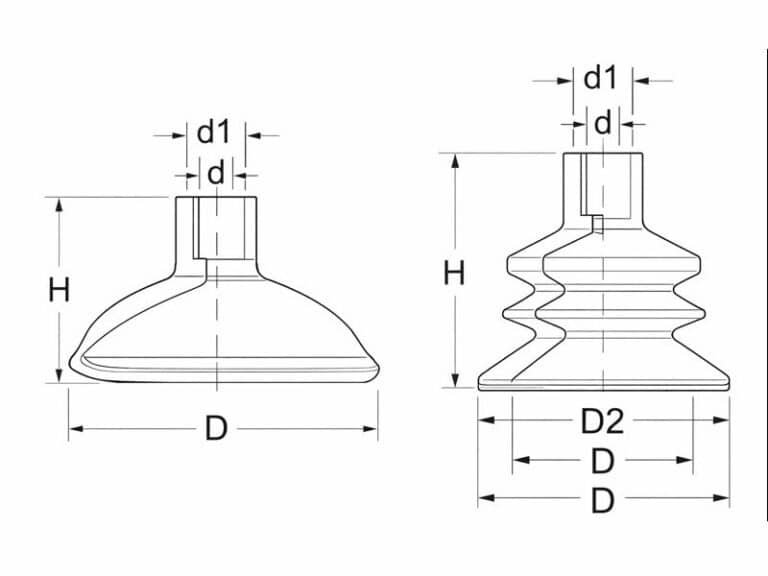

Flat Suction Cups

Flat suction cups are the most common type and are best suited for smooth, non-porous surfaces. These cups provide a strong grip on materials such as glass, metal, and plastic. They are ideal for applications where the surface is consistent and the material is stable.

Bellows Suction Cups

Bellows-style suction cups are designed with flexible, accordion-like segments that allow them to adjust to uneven or curved surfaces. These cups are ideal for handling materials that are not flat or have irregular shapes. They are often used in applications where flexibility and adaptability are necessary, such as in the packaging or automotive industries.

Special Lip Design Suction Cups

Suction cups with special lip designs are used for specific applications where extra suction power is needed. The lip helps create a better seal, improving the grip on materials that might otherwise be difficult to lift, such as irregularly shaped or porous items.

Oval or Rectangular Suction Cups

Oval or rectangular suction cups are designed to accommodate elongated or narrow materials. These shapes provide better coverage for items like bars or profiles, distributing the vacuum force along the length. Material handling suction cups of this type often use NBR for metal handling or PU for abrasive conditions.

Dual-durometer Suction Cups

Dual-durometer suction cups feature a combination of hard and soft layers. The outer soft lip grips delicate surfaces without damage, and the inner rigid body provides stability. These material handling suction cups match well with electronics or coated metals, using Silicone for the lip and PU for the base.

Common Problems in Material Handling and How to Avoid Them

Material handling suction cups can encounter issues that disrupt operations. Identifying and addressing these problems early maintains efficiency.

Leakage

Leaks can occur if the suction cup is not matched properly to the surface material or if the edges are worn. To prevent leakage, ensure that the suction cup material is compatible with the surface and that the correct size is chosen. Regular inspections should also be carried out to ensure that the suction cups are free from cracks or wear.

Surface Marking or Residue

Another problem is surface marking or residue left on handled materials. Hard or incompatible suction cup materials cause this, especially on polished surfaces. Prevention involves using soft Silicone or specialized non-marking compounds in material handling suction cups, along with cleaning protocols.

Dropping Items

Items may fall if the suction cup does not create a strong enough grip. This can be caused by selecting the wrong material or suction cup size. To avoid this, choose a suction cup with the correct lifting capacity and ensure that it is well-maintained.

Conclusion

Choosing the right material handling suction cups requires careful consideration of factors such as surface characteristics, material properties, and environmental conditions. While standard suction cups may work for many applications, specialized materials and designs are available for more demanding environments. Flexiparts provides a tailored solution for custom suction cups. Welcome to contact Flexiparts and get a custom solution.