Insert molding injection is a versatile manufacturing process that combines plastic with metal or other materials to create durable, high-performance components. Whether in the automotive, medical, or electronics industries, insert molding injection is crucial for producing parts that require additional functionality or durability. This article explores the benefits, applications, and considerations of insert molding injection, providing insights into how it can elevate the performance and reliability of various products.

What is Insert Molding Injection?

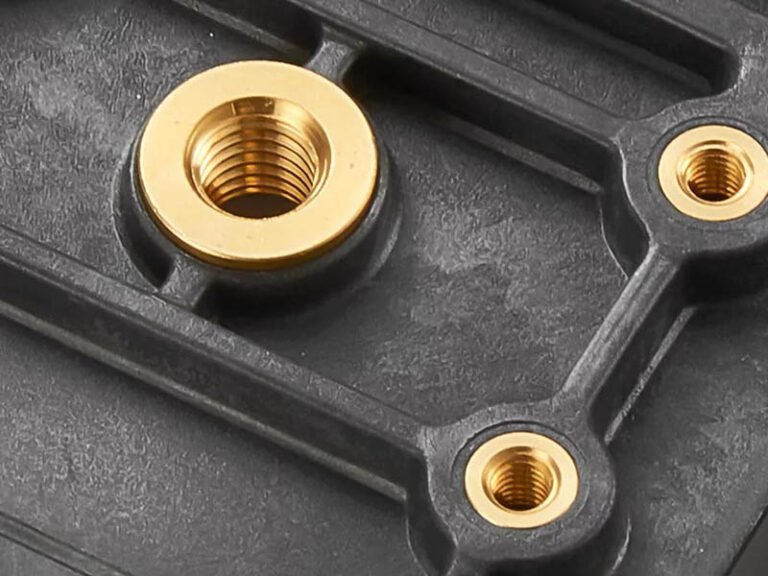

Insert molding injection is a specialized process that combines traditional injection molding with pre-formed inserts, such as metal, ceramic, or plastic components. These inserts are placed into the mold cavity before the plastic is injected, creating a multi-material part in a single molding step. This eliminates additional assembly, reduces production costs, and improves the final structural integrity.

Inserts can be made from metals (brass, steel, aluminum) for strength and wear resistance, ceramics for high-temperature applications, and plastics (polycarbonate, nylon, polypropylene) for insulation and flexibility. The selected plastic must bond well with the insert, considering factors such as mechanical strength, thermal properties, and electrical conductivity to ensure optimal performance and cost-effectiveness.

Insert Molding Injection Advantages and Disadvantages

- Advantages of Insert Molding: Insert moulding bonds metal parts or threaded inserts directly into the plastic during molding, creating a stronger, more reliable structure. It reduces secondary assembly steps, improves durability, and can lower overall production costs in volume.

- Disadvantages of Insert Molding: The process requires precise mold design and accurate insert placement, which increases complexity. Cycle time may be slower, and misalignment or poor material compatibility can lead to higher defect rates and more demanding quality control.

The Process of Insert Molding Injection

Insert molding injection is a precise and efficient manufacturing process that combines injection molding with the insertion of pre-formed components, or inserts, into the mold before plastic is injected. This technique results in multi-material parts that are stronger, more durable, and often more cost-effective than parts made from a single material. The steps are outlined below:

1. Preparation of Inserts

Inserts (e.g., metal, plastic, or ceramic) are pre-shaped components like rods, fasteners, or connectors, chosen based on the part’s design and function.

2. Mold Setup

The mold is designed to hold the inserts securely and align them properly during injection.

3. Insertion of Components

Inserts are manually or robotically placed into the mold cavity, ensuring accurate positioning for a secure bond.

4. Injection of Plastic

Molten plastic is injected, encapsulating the inserts and forming a strong bond. Material selection is critical for adhesion and performance.

5. Cooling and Solidification

The plastic cools and hardens, fully integrating the insert into the part. Cooling time depends on plastic type, part thickness, and mold design.

6. Ejection of the Finished Part

The mold opens, and the part is ejected with the insert permanently bonded, enhancing mechanical or functional properties.

7. Post-Processing (if needed)

Steps like trimming, cleaning, or quality checks ensure the part meets specifications.

Design Considerations for Insert Injection Molding

Designing for insert injection molding requires careful planning to ensure the process is successful and the final product meets high-quality standards. Key factors like material compatibility, insert placement, mold design, and cooling efficiency must be taken into account, along with choosing a reliable insert molding company.

1. Material Compatibility and Selection

Selecting the right materials is crucial. Metal inserts must bond securely with the plastic material, ensuring a strong, durable bond. Compatibility between the materials is essential to ensure the insert stays in place throughout the molding process.

2. Insert Placement and Orientation

Proper placement and orientation of the insert within the mold cavity are vital for optimal bonding between the plastic and insert. The insert must remain stable during injection to avoid misalignment and defects, ensuring uniform plastic flow around the insert.

3. Mold Design and Engineering

The mold design should accommodate both the insert and the plastic material. This includes careful consideration of cavity design, gate placement, and cooling systems to optimize material flow and prevent defects such as short shots or misfitting parts. Prevent defects such as short shots or misfitting parts.

4. Cooling and Cycle Time Optimization

The cooling system must ensure uniform cooling of both the plastic and insert, preventing defects like warping. Efficient cooling not only improves part quality but also optimizes the cycle time, increasing production efficiency.

5. Tolerances and Dimensional Accuracy

Precise mold design is necessary to ensure the insert stays in place and that the final part meets the required dimensional specifications. Tolerances should be controlled to ensure consistent part quality.

6. Cost Considerations

Insert moulding can be more expensive due to the cost of materials and mold design. Howeveroptimizing the design for efficiency can help reduce overall production costs. It’s important to consider material costs, maintenance, and labor costs during the design phase to maximize cost-effectiveness.

Applications of Insert Molding Injection

- Automotive Industry: Insert moulding is used to create durable automotive parts like connectors, brackets, and fasteners, combining metal inserts with plastic for added strength and resistance to heat and vibration.

- Electronics and Electrical Components: In electronics, insert moulding integrates metal inserts in components like connectors and housings, ensuring secure and high-performance parts, often essential for devices like circuit boards and sensors.

- Medical Devices: Used for surgical instruments and connectors, insert molding offers strength and corrosion resistance, making it ideal for medical device components that require cleanliness and durability.

- Consumer Goods: Insert moulding is employed in producing everyday items such as kitchen tools and personal care products, where plastic inserts combine with metal or ceramic for functional, cost-effective designs.

- Industrial Applications: Insert molding is ideal for industrial components like gears and mechanical housings, enhancing their strength and wear resistance with embedded metal inserts for long-term reliability.

- Aerospace and Defense: Critical parts for aerospace and defense, such as connectors and fasteners, benefit from insert molding’s ability to combine materials for high strength and resistance to extreme conditions.

- Plumbing and HVAC Systems: Insert molding is used to create leak-proof pipe fittings and connectors, often incorporating metal inserts for durability under pressure and temperature fluctuations.

Comparison Between Insert Molding Vs Overmolding

Insert molding and overmolding (what is the overmolding?) are both methods used to combine different materials into a single molded part, but they differ in their approach and use cases. Here’s a quick comparison of the two methods:

| Feature | Insert Molding | Overmolding |

|---|---|---|

| Process | A pre-formed insert is placed in the mold before plastic is injected around it. | A base part is molded first, then a second layer of plastic or elastomer is molded over it. |

| Material Integration | Uses rigid materials like metal inserts (steel, brass) for added strength and functionality. | Uses softer materials like rubber, TPE, or other elastomers for a protective or ergonomic layer. |

| Key Applications | Automotive, electrical components, medical devices, and industrial parts requiring strength or conductivity. | Power tool grips, toothbrush handles, consumer electronics, and products needing insulation or a soft-touch layer. |

| Design and Manufacturing Complexity | Requires precise placement of inserts, making the process more complex and tooling costs higher. | Generally simpler design but requires good adhesion between layers to avoid defects. |

| Cost Efficiency | More expensive due to pre-formed inserts and complex tooling, cost-effective for high-volume runs. | Can be cost-effective for adding soft-touch layers or protective coatings but may increase costs with multiple materials or complex designs. |

| Best For | Parts needing added strength, electrical conductivity, or threading, such as connectors and fasteners. | Parts requiring a soft-touch or protective coating, such as grips or outer layers. |

Conclusion

Insert molding injection offers a variety of benefits, including enhanced strength, durability, and functionality by embedding inserts such as metal or ceramic within plastic parts. Insert moulding is an ideal solution when parts need added durability or specific material properties that cannot be achieved with plastic alone. Common industries that leverage insert molding include automotive, medical, electronics, and industrial sectors. Flexiparts is a rapid manufacturer with reliable insert molding injection service.So if you need an expert to handle your insert molding or overmolding projects, Flexiparts is your best cooperator.