Injection moulding large parts service is a sophisticated process that plays a crucial role in the production of large, high-precision plastic components. As industries demand more complex, durable, and cost-efficient solutions, the capabilities of large part injection molding have expanded significantly. This article delves into the intricacies of injection moulding for large parts, exploring the techniques, materials, advantages, and key factors like injection pressure and clamping tonnage. Whether for automotive, industrial, or consumer products, understanding these elements can significantly impact the success of your large part manufacturing projects.

What is Injection Moulding Large Parts?

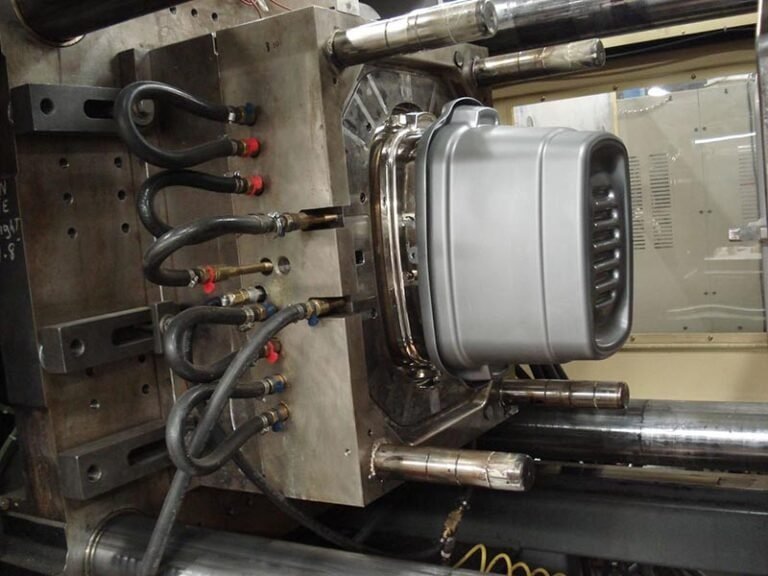

Injection moulding large parts refers to the process of producing substantial plastic components by injecting molten plastic into a mold under high pressure. This technique is commonly used in manufacturing large-scale, high-performance large molded plastic parts that require precision and durability. From automotive bumpers to industrial machinery components, the use of injection moulding for large parts is prevalent in a variety of industries. Unlike traditional moulding methods, this approach is specifically designed to accommodate larger geometries while maintaining the quality and consistency of smaller parts. It offers significant advantages when it comes to high-volume production, complex designs, and achieving a high degree of dimensional accuracy. The process requires careful consideration of factors such as injection pressure, clamping tonnage, material selection, and mold design to ensure the successful production of these larger components without defects. With the right techniques and equipment, large part injection molding offers a highly efficient and scalable solution for manufacturing high-quality large plastic parts components for large molds.

Critical Factors: Injection Pressure and Clamping Tonnage

The relationship between injection pressure and clamping tonnage is paramount for successful large part injection moulding.- Injection Pressure: This refers to the force with which the molten material is injected into the mold cavity. For injection moulding large parts, the pressure must be high enough to ensure the molten plastic fully fills the mold cavity, especially with intricate designs. This ensures the large part will have a consistent structure, free of air pockets or voids.

- Clamping Tonnage: This is the force applied by the machine’s clamping unit to keep the mold halves securely closed. Without sufficient injection moulding tonnage, the mold could open under the immense pressure, causing defects like flash or incomplete filling. As injection pressure increases, the required clamping tonnage also rises significantly to prevent the mold from opening.

Common Materials for Injection Moulding Large Parts

When selecting materials for injection moulding large parts, it is essential to choose substances that offer the necessary balance of strength, flexibility, and durability. Common materials include thermoplastics, such as ABS, polycarbonate (PC), polypropylene (PP), and high-density polyethylene (HDPE), as well as reinforced plastics like glass-filled nylon and carbon-fibre composites. These materials are selected based on their suitability for the intended application, taking into consideration factors such as temperature resistance, impact strength, chemical resistance, and ease of processing. For parts that require added strength and rigidity, materials like polyphenylene sulfide (PPS) or acrylonitrile butadiene styrene (ABS) are often preferred.

The Advantages of Injection Moulding Large Parts

The Advantages of Injection Moulding Large Parts lie in the unique capabilities of the process when applied to larger, more complex components.Ability to Produce Complex Geometries

Large part injection molding allows for the creation of intricate designs and complex shapes that are difficult or impossible to achieve with other manufacturing methods. For example, large automotive body panels, appliance housings, and intricate machinery components can be molded in one piece without the need for multiple assembly operations. This not only simplifies the design but also improves the overall strength and functionality of the part.Enhanced Structural Integrity

When producing large plastic parts, the injection molding process ensures uniform material distribution and minimizes stress points. The high-pressure injection process is particularly advantageous in ensuring that the part’s structural integrity is maintained. This reduces the likelihood of weak spots, warping, or material inconsistencies that can occur with other molding methods.Reduced Material Waste and High Production Efficiency

Compared to alternative manufacturing methods like CNC machining or casting, large part injection molding is highly material-efficient. The process allows for precise control over the amount of material used, significantly reducing scrap and waste. This is especially important when working with expensive polymers, as it makes large part production more cost-effective, particularly in high-volume manufacturing.Superior Surface Finish and Aesthetic Consistency

Large part injection molding is capable of producing components with an excellent surface finish and fine details directly from the mold. This often eliminates the need for extensive post-processing, such as sanding or painting, and ensures that every part in a production run maintains a high degree of aesthetic consistency, which is crucial for consumer-facing products like appliance housings and vehicle body panels.Flexibility in Material and Function Integration

The process supports a wide range of thermoplastic materials, allowing for the selection of specific properties like impact resistance, flame retardance, or chemical resistance. Furthermore, it allows for the integration of inserts (e.g., metal threads, connectors) directly into the part during the molding process. This capability reduces secondary operations and assembly costs, creating a more robust and functionally complete component in a single step.The Applications of Injection Moulding Large Parts

Injection moulding large parts is widely used across various industries due to its versatility and ability to produce high-quality, durable components. In the automotive sector, large parts like bumpers, dashboards, and exterior panels are commonly made using this technique. The examples of injeciton molding large parts as bellow:- Body panels (e.g., bumpers, door interior panels)

- Dashboard panels

- Door panels

- Wheel covers and trim pieces

- Machine housings (e.g., enclosures for motors, pumps, compressors)

- TV and monitor casings

- Refrigerator and washing machine panels

- Air conditioner housings and components

- Plastic chairs and tables

- Cabinets and plastic storage units

- Plastic sheds (outdoor storage units)