In conveyor systems, different idler roller types play an important role in maintaining smooth and efficient material transport. This article explores what idler rollers are, the common conveyor idler roller types, and how to choose the optimal idler roller for different applications.

What is an Idler Roller?

An idler roller is a cylindrical component fitted beneath or alongside a conveyor belt, designed to support and guide the belt as it carries bulk materials. These rollers are engineered for smooth rotation with integrated bearings to minimize friction and ensure efficient belt movement. Unlike drive rollers, idler rollers do not provide propulsion; instead, they support the belt load, maintain alignment, and help extend the system’s lifespan.

Idler rollers come in various materials, including plastic rollers and rubber rollers, each offering unique benefits depending on the application. Plastic rollers are lightweight, corrosion-resistant, and ideal for handling lighter materials or environments with high humidity. On the other hand, rubber rollers provide superior grip, making them well-suited for applications where traction and noise reduction are important. Choosing the right material for your idler roller ensures optimal belt tracking, reduces maintenance needs, and prevents costly downtime, making them essential for reliable conveyor system performance in demanding applications.

Common Types of Idler Rollers

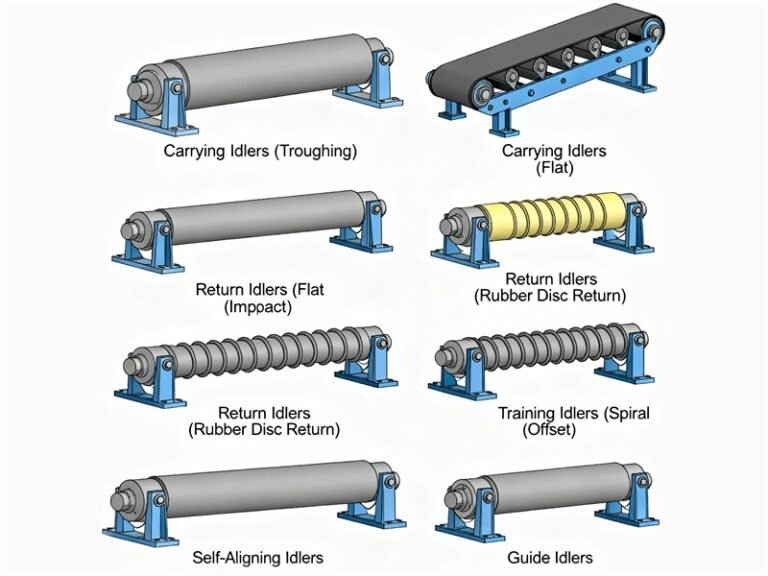

Idler roller types vary based on their specific functions in conveyor systems. Below are the primary types of idler rollers used in conveyor operations:

Carrying Idler Rollers

Carrying idler rollers support the loaded conveyor belt, distributing weight to prevent sagging and material spillage. They ensure the stable transport of heavy or voluminous materials. Typically arranged in configurations that maximize load capacity, they are built with durable materials to withstand constant pressure. Their design minimizes belt wear and maintains alignment, but regular cleaning is required to prevent material buildup.

- Troughing Idlers: Three rollers angled at 20–45° to form a U-shaped trough; used for bulk materials like coal or gravel to increase load capacity by up to 50%.

- Flat Carrying Idlers: Single flat roller for lighter loads, such as packaged goods in logistics, ensuring smooth transport with minimal friction.

- Garland Idlers: Linked rollers offering flexibility for uneven surfaces, ideal for rugged terrains in mining or quarrying applications.

Return Idler Rollers

Return idler rollers support the empty belt on the return side of the conveyor as it travels back for another load cycle. Typically, these are flat rollers designed to prevent belt sagging and stretching, which could otherwise lead to premature belt failure.

- V-Return Idlers: Two rollers in a V configuration; stabilize the empty belt and often include spiral rollers to remove debris in recycling operations.

- Flat Return Idlers: Single roller for simpler systems; supports the empty belt in low-debris environments like food processing.

- Rubber-Disc Return Idlers: Feature rubber discs to enhance debris shedding; used in sticky material handling to minimize buildup.

Training Idler Rollers

Training idler rollers correct belt misalignment, ensuring the belt remains on track during operation. These conveyor idler types are vital for long or high-speed conveyors, such as those in warehouses, where even slight deviations can cause significant downtime or damage. Equipped with pivoting mechanisms, they automatically adjust belt positioning, reducing manual maintenance but requiring a higher initial investment.

- Self-Aligning Trough Idlers: Pivoting trough design for bulk material conveyors; corrects misalignment in heavy-duty systems like mining.

- Self-Aligning Flat Idlers: Flat pivoting roller for lighter systems; maintains alignment in warehouse or packaging lines.

- Guide Roller Idlers: Side-mounted rollers; guide the belt edges in narrow conveyors to prevent lateral drift.

Impact Idler Rollers

Impact idler rollers absorb shocks at loading points, protecting the belt from damage caused by falling materials. Featuring cushioned surfaces, they extend belt life but require regular maintenance to ensure cushioning effectiveness.

- Rubber-Disc Impact Idlers: Equipped with rubber discs; absorb shocks in quarries, protecting belts from heavy rock impacts.

- Cushioned Impact Idlers: Full rubber coating; used in aggregate handling to minimize belt tears at transfer points.

- Reinforced Impact Idlers: Heavy-duty frames with cushioning; designed for extreme impacts in mining or steel production.

Custom Idler Rollers

In many conveyor applications, especially demanding or specialized ones, custom idler rollers provide vital solutions tailored to unique operational needs. Customizable features can include dimensions, materials, surface coatings, and special functions.

- Tapered Idlers: Designed for curved conveyors, they guide belts around bends and reduce edge wear in systems like airport baggage handling.

- Rubber-Coated Idlers: Equipped with rubber layers to reduce belt wear, noise, and vibration, also providing some material cushion.

- Heavy-Duty Idlers: Built with reinforced frames, oversized shafts, and durable bearings to handle heavy loads, harsh environments, or continuous operations.

How to Choose the Right Idler Roller?

Selecting the appropriate idler roller types requires evaluating several factors. Here are key parameters to guide the choice:

Material Type: Bulk materials vary widely in abrasiveness, size, weight, and moisture content. Steel idlers are suitable for abrasive materials like ore, while HDPE idlers resist corrosion in chemical handling. Incorrect material choices can lead to rapid deterioration.

Load and Speed: The weight of the conveyed load, combined with the conveyor belt speed, influences idler strength and durability requirements. High-speed conveyors may need low-friction, precision rollers to reduce heat build-up and energy consumption.

Belt Width and Conveyor Length: Wider belts and longer conveyors often need more idlers spaced at specific intervals to support weight and maintain belt shape. Larger belts may also require idlers with greater load ratings.

Operating Environment: Temperature extremes, moisture, dust, chemicals, or corrosive atmospheres affect material choice for idler frames, shaft coatings, and seals. For example, stainless steel idlers may be needed in wet or corrosive environments.

Maintenance and Lifecycle Costs: Ease of maintenance, bearing quality, seal protection, and availability of replacement parts impact the total cost of ownership. High-quality idlers with effective sealing reduce downtime and extend service intervals.

Conclusion

By carefully considering factors like material characteristics, load, speed, environmental conditions, and maintenance needs, one can select the ideal conveyor idler types to optimize system performance and longevity. Additionally, the idler roller forming process, such as overmolding, plays a key role in enhancing the durability and performance of the rollers. At Flexiparts, we utilize overmolding and other advanced manufacturing techniques to ensure that our idler rollers are robust, efficient, and well-suited for various operating environments. For tailored conveyor roller and belt solutions, contact us today.