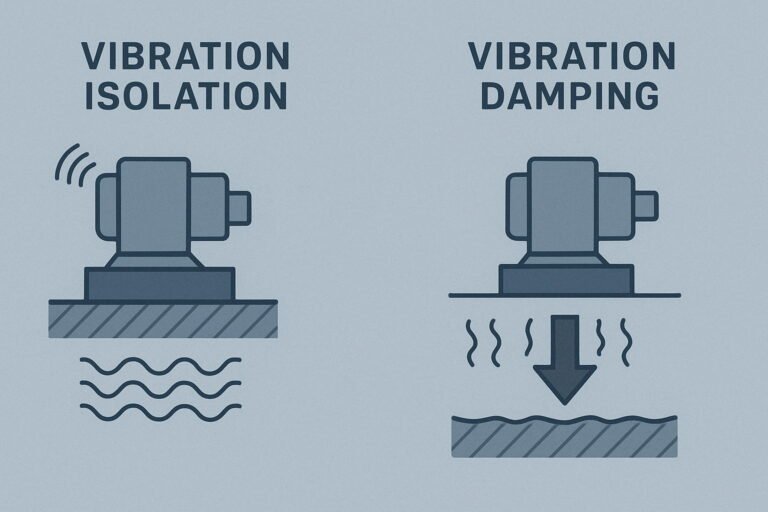

Vibration is an inevitable physical phenomenon that, if left uncontrolled, can reduce efficiency, safety, and product lifespan. At the physical level, vibration control relies on two main approaches: vibration isolation reduces the transmissibility of vibrational energy, preventing it from propagating into sensitive components rather than absorbing it. vibration damping, which absorbs and dissipates energy within a system to reduce vibration amplitude and duration.Understanding the differences between these methods is the first step toward choosing the right solution for your application.

Differences between Vibration Isolation and Damping

While vibration isolation focuses on reducing the transmission of vibration, vibration damping works by absorbing and dissipating energy within the structure to decrease vibration amplitude and decay time.

Passive Vibration Isolation

Passive vibration isolation relies on mechanical components, including mass, springs, and dampers, without requiring external power. The mass (e.g., the equipment itself) defines the payload, the spring determines the system’s natural frequency, and the damper mitigates resonance. These systems are bidirectional, meaning they protect both the equipment from external vibrations and the environment from the equipment’s oscillations. Passive systems shine in simplicity and reliability. They’re cost-effective, easy to install, and ideal for high-frequency vibrations.

Active Vibration Isolation

Active vibration isolation is a sophisticated solution for low-frequency challenges. These systems use sensors to detect vibrations, actuators to generate counteracting forces, and control algorithms (feedback or feed-forward) to neutralize oscillations in real-time. Active systems excel in low-frequency vibration isolation, often handling oscillations below 1 Hz, where passive systems falter. However, they are typically more complex, costly, and require continuous power and calibration.

Factors to Consider When Choosing a Vibration Isolator

Selecting the appropriate vibration isolator involves several critical factors, ensuring the isolation system efficiently addresses the vibrational issues present.

- Vibration Frequency and Amplitude: Understanding the frequency content of the vibration source is paramount. Isolators must be designed to minimize transmissibility around the system’s natural frequency and effectively handle the dominant excitation frequencies.

- Mass and Dynamic Characteristics of Equipment: The weight and inertia of the equipment influence the natural frequency of the isolation system. Isolators must be matched to the load to maintain optimal vibration isolation performance without overstress.

- Transmissibility and Natural Frequency: The goal is to have the isolator’s natural frequency significantly lower than the operational excitation frequencies. This frequency ratio (also called the frequency ratio) dictates how well the system isolates vibration. Effective vibration isolation and damping systems reduce the transmissibility, the measure of vibrational force transmitted through the system.

- Damping Properties: While high damping usually means better energy absorption and less transmitted vibration, too much damping can inadvertently transfer more vibration, especially near resonance conditions. The isolator’s damping characteristics should achieve a balance for stability and isolation efficiency.

- Environmental Conditions: Factors such as temperature fluctuations, exposure to moisture, chemical agents, and UV exposure can affect isolator materials. Durability and material selection must align with these environmental demands.

- Installation Constraints: Space limitations, load distribution, and ease of maintenance are practical considerations that influence isolator type and configuration.

Conclusion

For industries facing challenging vibration control demands, selecting the right solution can make a world of difference in operational efficiency and product longevity. FlexiParts provides advanced vibration isolation and damping solutions tailored to your equipment and operating environment. Contact us today to discuss a custom solution for your vibration control needs.