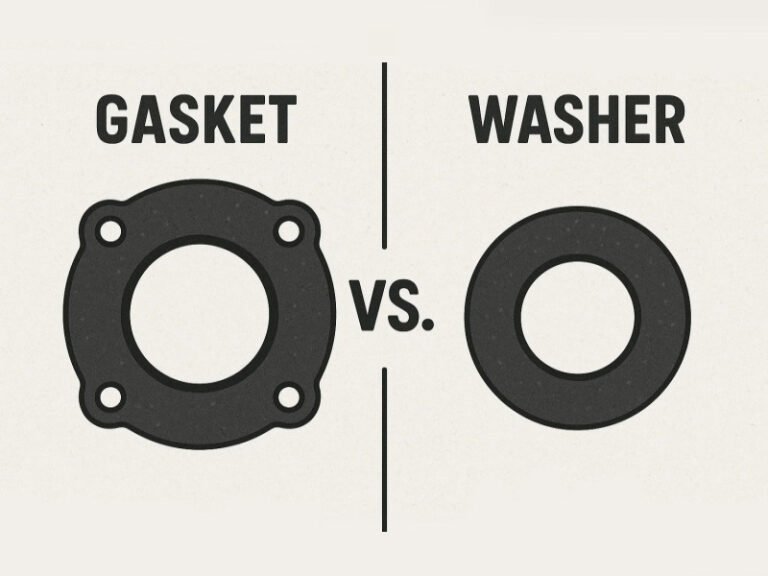

At first glance, washers and gaskets might seem like interchangeable components in mechanical assemblies. Both are often flat, disc-shaped, and feature a central hole, leading many to assume they serve similar purposes. However, the difference between gasket and washer lies at the heart of their functionality, and mistaking one for the other can result in costly mechanical failures, from loosened fasteners to catastrophic leaks. Now, let’s clarifying the gasket vs washer debate to ensure proper application in any project.

What is a Washer?

A washer is a thin, typically circular component with a central hole, designed to work in tandem with fasteners such as bolts, screws, or nuts. Its primary role is to distribute the load of the fastener across a wider surface area, preventing damage to the underlying material. Beyond load distribution, washers serve multiple purposes: they reduce vibration, act as spacers, prevent galvanic corrosion between dissimilar metals, and, in some cases, provide limited sealing capabilities.

For specific needs, many industries rely on plastic washer manufacturers to provide durable, lightweight washers that can withstand environmental stresses while offering the right combination of flexibility and resistance.

Common Types of Washers

Washers come in various types, each tailored to specific applications:

Flat Washers: The most common type, these evenly distribute load to protect surfaces, especially soft materials like wood or plastic.

Lock Washers: Featuring split or toothed designs, lock washers grip the fastener to prevent loosening in high-vibration environments, such as automotive assemblies.

Spring Washers: Conical in shape to absorb shock and maintain tension, ideal for machinery subject to thermal expansion or contraction.

Fender Washers:With a larger outer diameter, fender washers spread load over a broader area, often used in automotive or sheet metal applications.

Sealing Washers: Equipped with rubber or silicone inserts, these provide minimal sealing for specific low-pressure applications.

Insulating Washers: Made from non-conductive materials like nylon, these prevent electrical current transfer in sensitive assemblies.

Materials of Washers

Washers are predominantly crafted from rigid materials to withstand compressive forces. Metals like stainless steel, carbon steel, brass, and aluminum are common due to their strength and corrosion resistance. For specialized applications, non-metallic materials such as nylon, plastic, or rubber are used, particularly for insulation or light sealing purposes.

What is a Gasket?

A gasket is a mechanical seal designed to fill the space between two mating surfaces, preventing leaks of fluids or gases under pressure. Unlike washers, which focus on fastener stability, gaskets are all about creating a tight, reliable seal. They are critical in static applications, such as pipe flanges, engine blocks, or pump housings. Gaskets conform to surface irregularities, ensuring a pressure-tight barrier in demanding environments.

Common Types of Gaskets

Gaskets vary widely in shape and design to suit specific applications:

Sheet Gaskets: Cut from flat materials like rubber or cork, these are versatile and customizable for various shapes and sizes.

Spiral-Wound Gaskets: Combining metal and filler materials, these excel in high-pressure, high-temperature applications.

O-Rings: Circular seals used in both static and dynamic applications, such as hydraulic systems or plumbing.

Ring Type Joints (RTJ) Gaskets: Made from metals like stainless steel, these are designed for extreme conditions, such as high-pressure oilfield equipment.

Custom-Molded Gaskets: Tailored for unique machinery or components, these ensure precise sealing in specialized applications.

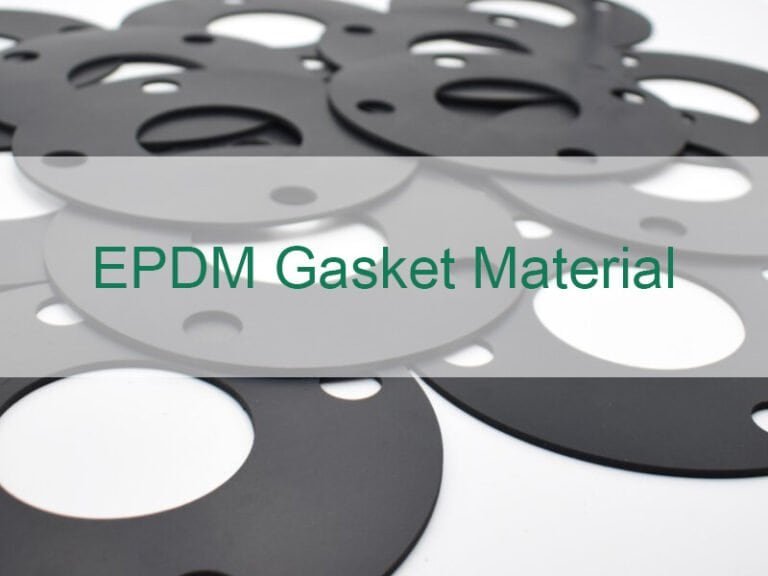

Materials of Gaskets

- Rubber (Nitrile, Neoprene, Silicone)

- Cork

- Felt

- Asbestos-free compressed fiber sheets

- PTFE (Polytetrafluoroethylene)

- Metal alloys (stainless steel, copper)

- Composite materials combining metal and elastomeric fillers

Key Differences Between Washers and Gaskets

The gasket vs washer distinction boils down to their core functions, materials, and applications. The following table summarizes the key differences:

| Aspect | Washer | Gasket |

|---|---|---|

| Purpose | Distributes load, stabilizes fasteners | Distributes load, stabilizes fasteners |

| Material | Rigid (metal, plastic, nylon) | Pliable (rubber, silicone, cork, metal) |

| Shape | Typically circular, uniform | Varies widely (circular, rectangular, custom) |

| Application | Used with fasteners (bolts, screws) | Used between mating surfaces (flanges, pipes) |

| Sealing Capability | Limited (only in sealing washers) | Designed for fluid/gas sealing |

How to Choose the Correct Washer or Gasket?

To choose the correct washer or gasket, first understand their roles: washers support fasteners, while gaskets prevent leaks between surfaces. If you’re looking for plastic washers, you might consider a plastic washer manufacturer for a tailored solution. For gaskets, consult with a rubber gasket supplier to ensure the material matches your application’s pressure, temperature, and chemical resistance needs. Whether you’re dealing with gaskets vs seals in a high-pressure system or a low-stress application, selecting the right component is essential for ensuring longevity and safety.

Conclusion

In sum, while washers and gaskets may look similar, their function, design, and materials differ fundamentally. Recognizing these differences is a key step in sound mechanical design and maintenance. You also can consult with Flexiparts engineers and get a professional custom solutions.