In power transmission systems, gears and pulleys are both workhorses. They help move power, change speed, or redirect motion. But while they sometimes serve similar purposes, their design, performance, and ideal use cases are very different.

This article keeps things simple. By the end, you’ll know:

- What gears and pulleys are

- pulley vs gear pros and cons

- When to choose one over the other

What Is a Gear?

Gears are those familiar toothed wheels you see in car gearboxes, robots, or even clocks. When two gears mesh, they transfer power directly and precisely, without slipping or delay. They’re ideal when you need high torque to handle heavy loads, precise control over speed or direction, and a compact design that delivers a lot of power in a small space. Depending on the application, you can choose from common gear types like spur gears, helical gears, or bevel gears, each designed for specific performance needs. Plastic gears are also used in applications where lower torque, reduced weight, and quieter operation are desired, such as in small appliances, toys, or certain types of medical devices.Advantages of Gears

- High Efficiency: Transfers power with minimal loss (up to 98%).

- No Slippage: Delivers precise, synchronized motion.

- Durable: Handles heavy loads and long operating hours.

- Compact Design: Packs high torque into small spaces.

Disadvantages of Gears

- Higher Cost: More expensive to produce and maintain.

- Noisy Operation: Can get loud at high speeds.

- Needs Lubrication: Requires regular maintenance.

- Less Shock Resistance: Sudden loads can damage gear teeth.

- Fixed Layout: Hard to adjust speed or layout after installation.

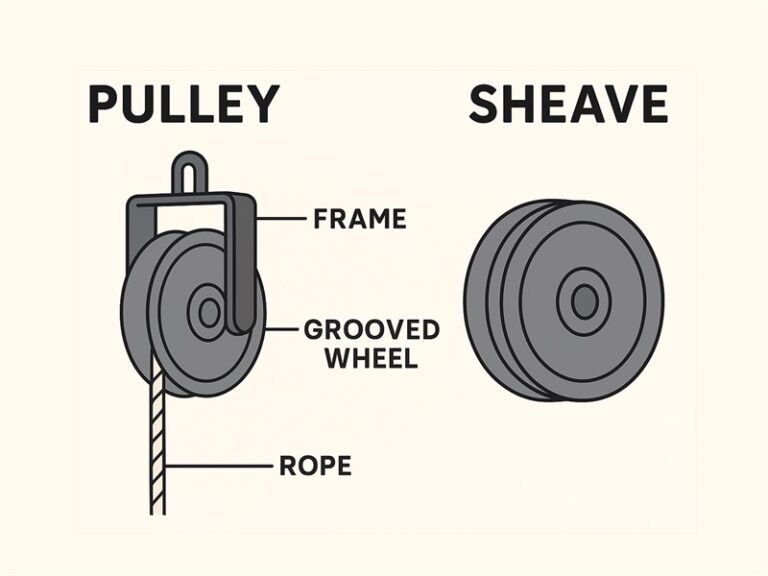

What Is a Pulley?

Pulleys use a belt or rope running over a grooved wheel to transfer power. They are the go-to choice when you need flexibility over long distances or in systems with changing layouts. Think of conveyor belts, elevators, or agricultural machinery. Pulleys make power transfer simpler and more versatile. They are great for transmitting power across long distances from one end of a factory to the other. They also allow easy speed adjustment by changing pulley sizes. Plus, belts naturally absorb shocks and reduce vibration, keeping the system running smoothly. Plastic pulleys are also used in certain applications where weight reduction, corrosion resistance, and quieter operation are important, such as in light-duty machinery or consumer products.Advantages of Pulleys

- Cost-Effective: Belts and pulleys are inexpensive and easy to replace.

- Quiet Operation: Runs smoothly with low noise.

- Flexible Layouts: Works over long distances and complex paths.

- Shock Absorption: Belts reduce vibration and protect equipment.

Disadvantages of Pulleys

- Lower Efficiency: Some power is lost due to belt slip or stretch.

- Limited Load Capacity: Not for extremely heavy loads.

- Belt Maintenance: Belts need regular tensioning and replacement.

- Speed Variation: Belt stretch can affect accuracy over time.

- Space Requirement: Needs more installation space than gears.

Gear vs Pulley: Side-by-Side Comparison

| Aspect | Gears | Pulleys | Best For |

|---|---|---|---|

| Power Transfer | Direct tooth engagement, no slip | Belt-driven, may allow slight slip | High precision vs long distance |

| Efficiency | 95–98%, very high | 85–95%, slight losses possible | High efficiency → gears |

| Shaft Distance | Short, fixed spacing | Long or flexible spacing possible | Space-constrained → pulleys |

| Maintenance | Requires lubrication, higher cost | Low cost, easy belt replacement | Cost-sensitive → pulleys |

| Noise & Vibration | Louder, more vibration | Quieter, shock-absorbing | Noise-sensitive → pulleys |

| Load Capacity | Handles high torque, heavy loads | Moderate loads, long spans | Heavy-duty → gears |

| Shock Resistance | Lower, can damage teeth | Higher, belts cushion sudden loads | Shock-prone → pulleys |

How to Choose Between Gears and Pulleys?

Here’s a quick rule of thumb:

- Choose Gears if you need precision, high torque, or compact design, like in robots, automotive gearboxes, or CNC machines.

- Choose Pulleys if you need low-cost, flexible, or long-distance power transmission, like in conveyors, elevators, or HVAC systems.

In one sentence: Gears focus on accuracy and power, while pulleys focus on flexibility and cost-efficiency.

Flexiparts Custom Solutions

Whether you need high-precision gears or versatile pulley systems, Flexiparts provides custom mold design, material selection, and manufacturing services. Our engineers assist you in choosing the right solution for your application, ensuring a balance of efficiency, cost, and durability for the best results.