Gaskets are essential components in many industries, providing a reliable seal between surfaces to prevent leaks of liquids, gases, or other substances. At the heart of their effectiveness lies the materials they are made from. From flexible rubber to sturdy metals, from heat-resistant graphite to versatile plastics, each gasket material brings unique properties that make it suitable for specific applications.

Understanding these materials is key to selecting the right gasket for the job and ensuring safe, stable, and efficient operation. Gasket materials are generally grouped by their composition and characteristics, with each type offering distinct advantages for different sealing needs. There are primary types of gasket materials:

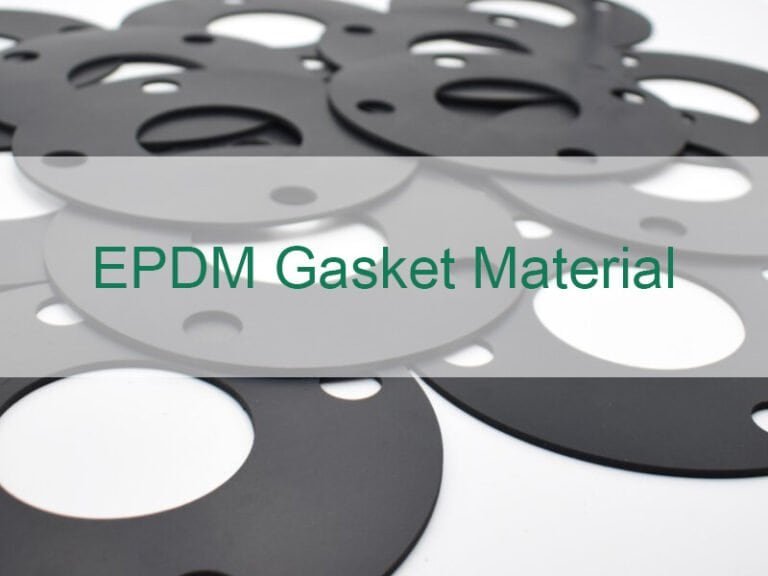

Rubber Gasket Materials

Offers elasticity, good compression resilience, and corrosion resistance. Specific formulations provide tailored resistance to oils, chemicals, weathering, or temperature (up to 200°C for silicone rubber gasket.

- Nitrile (Buna-N): Resists oils, fuels, and solvents; used in automotive fuel systems and hydraulic seals.

- Neoprene: Withstands weathering, ozone, and moderate chemicals; ideal for HVAC systems and outdoor seals.

- Silicone: Flexible, heat-resistant (up to 200°C), and FDA-approved; used in food-grade and medical applications.

- EPDM: Excellent resistance to water, steam, and UV; common in water pumps and marine applications.

- Viton® (Fluorocarbon): High chemical and heat resistance; used in chemical processing and aerospace seals.

- Butyl: Low gas permeability; suited for vacuum sealing and air conditioning systems.

- Polyurethane: Abrasion-resistant; used in heavy-duty industrial seals.

Plastic Gasket Materials

Plastic gaskets are lightweight, corrosion-resistant, and versatile, making them suitable for a wide range of applications where metal or rubber may not be ideal. They offer good chemical resistance, dimensional stability, and low moisture absorption. Common types include:

- PTFE (Teflon): Excellent chemical resistance and low friction; widely used in chemical processing, food, and pharmaceutical industries.

- Polypropylene (PP): Lightweight, resistant to acids and alkalis; often used in water treatment and piping systems.

- Polyethylene (PE): Economical and resistant to moisture; suitable for low-pressure applications and general-purpose seals.

- PVC: Flexible and corrosion-resistant; used in plumbing and electrical enclosures.

Plastic gasket materials are ideal when chemical exposure, low weight, or dimensional stability is critical, providing a reliable alternative to rubber or metal gaskets in many industrial settings.

Foam Materials of Gasket

Foam gaskets, including sponge rubber and plastic-based foams, offer excellent compressibility, lightweight properties, and sealing performance under low pressure. They are commonly used in enclosures, automotive weather seals, and electronics.

- Closed-Cell Sponge Rubber: Resists water ingress and provides excellent weather sealing.

- Open-Cell Sponge Rubber: Breathable structure allows airflow; used for cushioning and filtration.

- Conductive Foam: Combines compressibility with EMI shielding; used in electronic device enclosures.

- PE and PU Foam: Lightweight and economical; used in packaging, HVAC gaskets, and insulation applications.

![]()

Non-Metallic Fiber Gasket Materials

Lightweight, resistant to corrosion, and easy to manufacture. They offer moderate tensile strength.

- Asbestos (historical use): Once widely used for its excellent heat resistance and sealing properties, but now largely replaced due to health concerns.

- Aramid Fiber (e.g., Kevlar): High tensile strength; used in water pumps and moderate-pressure flanges.

- Cellulose Fiber: Economical, paper-like material; used in low-pressure seals like oil pan gaskets.

- Vegetable Fiber (e.g., Detroiter): Eco-friendly, used in low-stress applications like plumbing.

Gasket Composite Materials

Offer enhanced durability over standalone rubber or fiber, with moderate resistance to temperature, pressure, and chemicals.

- Rubber/Aramid Blends: Combine flexibility and strength; used in pipeline flanges and general industrial seals.

- Cork/Rubber (e.g., Cork/Nitrile): High compressibility with oil resistance; used in automotive gaskets and valve covers.

High-Performance Gasket Materials

Withstand temperatures up to 450°C (graphite) or 260°C (PTFE) and aggressive chemicals.

- PTFE (Teflon): Near-universal chemical resistance; used in chemical processing and pharmaceutical seals.

- Flexible Graphite (e.g., Grafoil®): High heat resistance; used in steam systems and high-pressure flanges.

- Ceramic Fiber (e.g., Fiberfrax®): Extreme heat resistance; used in furnace seals.

Metallic Gasket Materials

High strength and resistance to deformation. Less flexible than rubber gasket material.

- Stainless Steel (Spiral-Wound): Durable under extreme pressure; used in oil refineries and petrochemical plants.

- Copper/Aluminum: Conductive and corrosion-resistant; used in high-pressure heat exchangers.

Electromagnetic Shielding Materials

Combine conductivity with sealing properties, often using conductive rubber gasket material.

- Conductive Silicone Rubber: Shields electronics; used in aerospace and telecommunications enclosures.

- Chomerics® Metalastic: High conductivity; used in sensitive electronic devices.

How to Choose the Right Gasket Material — Key Points

1. Check Operating Conditions:

Consider temperature, pressure, and chemicals involved. Choose materials like nitrile for oils, PTFE for corrosives, and silicone for heat.

2. Match Physical & Environmental Needs:

Look at flexibility, surface finish, and exposure to UV or ozone. Use softer foams for rough surfaces, neoprene for outdoor use.

3. Ensure Compliance & Cost Efficiency:

Confirm standards (ASTM, UL, mil-spec) are met and balance cost with performance.

4. Special Requirements:

Use conductive rubber for EMI shielding and metals for extreme pressure or temperature.

Conclusion

Whether it’s flexible rubber or strong metal, the right gasket material ensures smooth and reliable operation. Flexiparts delivers high-quality, uncommon gasket material, custom solutions, and expert support, helping you maintain performance and peace of mind. Contact us to discover the ideal gasket for your application.