Belts and pulleys work in tandem to transmit power between rotating shafts. The belt, a flexible looped component typically made from materials like rubber, nylon, or polyurethane, wraps around pulleys, which are cylindrical wheels with grooves or smooth surfaces. When the driving pulley rotates, it moves the belt, which in turn rotates the driven pulley. This system enables the transfer of torque and rotational speed, facilitating movement or operational functions in machines.

Types of Belts and Pulleys

Belts and pulleys come in several types to suit different transmission needs. Each type has specific structural features and applications.

Belt Types

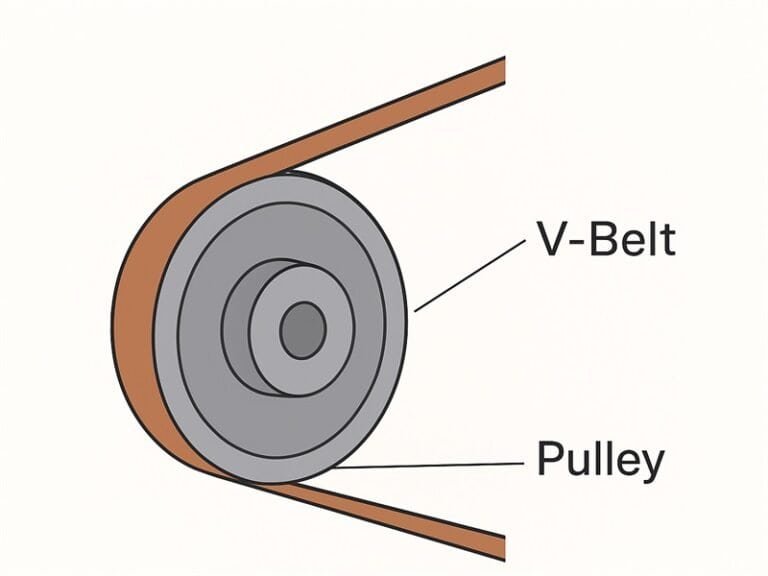

V-Belts: V-belts feature a trapezoidal cross-section with a 40-degree angle. They consist of multiple layers, including an outer wear-resistant cover and an inner load-bearing core. Their shape ensures better grip and less slippage by wedging into the pulley grooves, making them suitable for high-torque and moderate-speed applications.

Timing Belts: These belts feature teeth on the inner surface that mesh with matching teeth on the pulley. They are constructed from polyurethane or rubber with fiber reinforcement. Timing belts ensure precise synchronization without slippage and are used in CNC machines and engine timing systems.

Flat Belts: Flat belts have a rectangular cross-section and are made from materials like rubber or fabric. They provide flexibility for long-distance transmission. Flat belts suit low to medium load conditions and are used in conveyors and agricultural machinery.

Round Belts: Circular in cross-section, round belts are flexible and commonly used in light-duty power transmission, such as in sewing machines or small appliances.

Ribbed or HTD Belts: Ribbed or HTD belts have multiple ribs or arc-shaped teeth for noise reduction and high load capacity. They use fiber-enhanced materials. Ribbed belts fit HVAC compressors and electric vehicles.

Pulley Types

Flat Belt Pulleys: Flat belt pulleys have a smooth surface without grooves and are made from cast iron or aluminum for lightweight. They match flat belts and are used in low-speed, long-distance applications such as sawmills.

V-Belt Pulleys: V-belt pulleys include V-shaped grooves at 34 to 40 degrees, often with multiple grooves to increase power. V-belt pulleys support high-load industrial tasks like conveyor drives and pump operations.

Timing Belt Pulleys: Timing belt pulleys have grooved teeth to match timing belts and are precision-machined from steel or aluminum. They ensure accurate power transfer and are applied in robotic arms and synchronized systems.

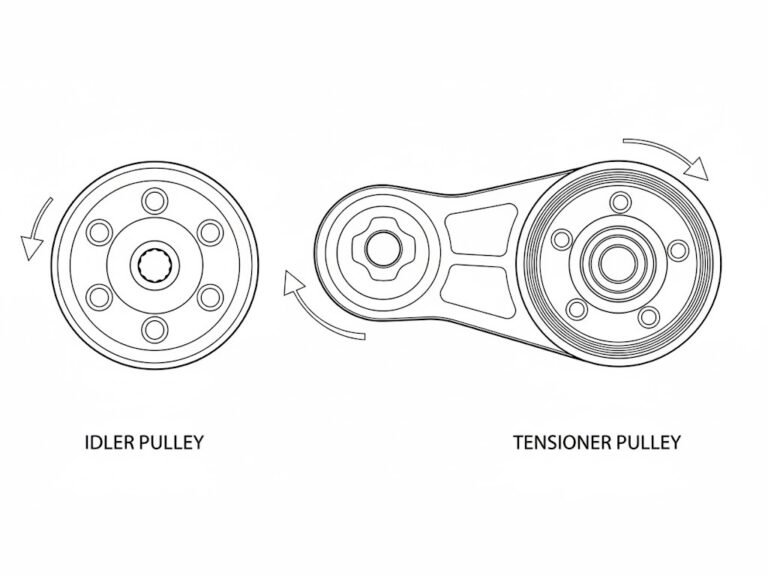

Idler Pulleys: Idler pulleys do not transmit power. They are used primarily to change the belt’s direction, adjust tension, or guide the belt path. Idler pulleys maintain belt alignment in multi-belt configurations.

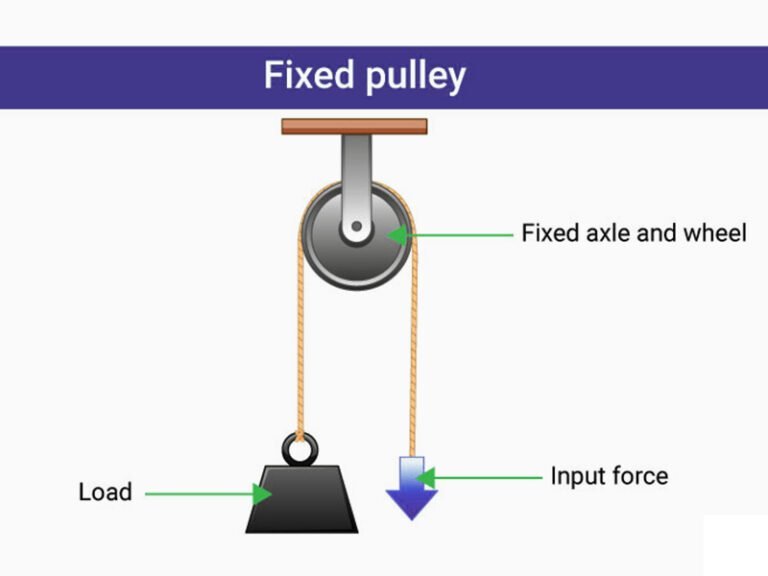

Fixed/Moved/Compound Pulleys: Fixed, movable, or compound pulleys provide direction changes or mechanical advantage. Fixed pulleys attach to stationary shafts, movable ones adjust tension, and compound types combine multiple wheels. They are used in lifting equipment and well pumps.

Advantages of Using Belts and Pulleys

- Belts and pulleys offer efficient power transmission. They achieve efficiencies between 90 and 98 percent with low energy loss. This is higher than some gear systems.

- Maintenance is low for belts and pulleys. They require no lubrication, only regular tension checks. This reduces operational time compared to chains.

- Belts and pulleys tolerate minor shaft misalignments up to 5 to 10 degrees. This prevents system failures in setups with slight offsets.

- Overload protection is built into belts and pulleys. Belts slip under excessive load, avoiding damage to motors or shafts. This feature helps in agricultural equipment where loads vary.

- Costs are low for belts and pulleys. Initial setup expenses are minimal, and they last 3 to 5 years under normal use. Replacement is straightforward.

- Belts and pulleys reduce vibration and noise. They absorb shocks, making them suitable for environments with dust or corrosion, from -35°C to 85°C.

- Speed variation is possible with belts and pulleys. Step pulleys allow RPM adjustments without part changes. This adds flexibility to operations.

Customization Considerations for Belt and Pulley Compatibility

When customizing belts and pulleys for specific machinery or operational contexts, several important factors must be carefully evaluated to ensure system efficiency and durability:

Type Matching

Match belt types to pulley types. For instance, V-belts require pulleys with compatible grooves, while timing belts need toothed pulleys. Using incompatible types can lead to slippage, premature wear, or failure.

Size Compatibility

Pulley diameter and belt length must be chosen to suit the required speed ratios and torque loads. Precise measurements and tolerance allowances prevent belt misfit and ensure smooth transmission.

Material and Strength

The materials used for belts and pulleys affect performance and longevity. Belts might be reinforced with fibers for added strength, while pulleys are selected based on environmental exposure and mechanical stress.

Transmission Conditions

Load, speed, operating temperature, and environmental factors influence the selection process. Heavy loads or high speeds may necessitate wider or specialty belts and stronger pulleys to handle stress safely.

Applications of Belts and Pulleys

Belts and pulleys power a vast array of applications across many industries due to their adaptability and efficiency:

- Industrial Machinery: Conveyors, compressors, fans, and pumps.

- Automotive: Engines, water pumps, and air conditioning compressors.

- Agriculture: Equipment such as tractors and harvesters.

- Household Appliances: Washing machines, dryers, and vacuum cleaners.

- HVAC Systems: Belt-driven fans and blowers.

Common Issues with Belts and Pulleys

Belts and pulleys face several issues that affect performance.

- Belt Slippage: Insufficient tension or heavy wear can cause the belt to slip across the pulley groove, significantly reducing power transmission efficiency and generating excessive heat.

- Misalignment: Improper pulley alignment causes the belt to track incorrectly. This leads to uneven belt wear, accelerated pulley damage, increased operational noise, and excessive vibration.

- Material Wear: Over time, belt materials degrade due to high operating heat, internal friction, and exposure to harsh environmental elements like ozone or chemicals, requiring timely replacement.

- Tension Loss: This occurs when the belt stretches or due to pulley groove wear. Loss of correct tension compromises the system’s ability to transmit power efficiently and can lead to damaging vibration.

- Foreign Matter and Abrasion: Dirt, sand, or debris on running surfaces dramatically increases friction. This abrasion can cut the belt’s internal tension fibers and permanently alter the pulley groove geometry, leading to premature failure.

- Shock Load and Structural Failure: Sudden, high-impact load changes can impose extreme stress on the belt structure. This may cause the belt to break instantaneously (snap) or result in the teeth separating from the belt body, leading to complete drive failure.

Conclusion

Compatibility between belts and pulleys determines transmission efficiency and lifespan. Proper matching of types, sizes, materials, and conditions prevents slippage and early wear. Flexiparts provides customized service for belts and pulleys. Welcome to contact us and get a custom solution.