What Is a V-Belt Pulley?

A V-belt pulley is a wheel with a V-shaped groove that works with a V-shaped belt to transmit power between parallel shafts. This V shape fits snugly into the pulley groove, creating friction that efficiently transmits power while minimizing slippage. Compared to flat belts or round belts, the V-belt design improves grip and power transfer thanks to the increased surface contact and wedging action.

For heavy-duty use, they’re typically made of cast iron, steel, aluminum, or zinc. Non-metal materials like engineering plastics (e.g., nylon or POM) are also used in lighter applications where weight and cost-effectiveness are key.

The Importance of V Belt Pulley

V-belt pulleys combine efficiency, flexibility, and durability with low maintenance requirements. The design allows for smooth and quiet transmission of power, absorbing shocks and vibrations that can otherwise damage machinery. Their reliability stems from reducing belt slip, which leads to better energy efficiency and less wear on both belt and pulley. Moreover, V-belt pulleys maintain correct speeds and torques between motor shafts and driven components.

Different Types of V Belt Pulleys

V-belt pulley types vary to meet different power, speed, and application needs. The primary types include:

- Single-groove V Belt Pulleys: Single-groove V-belt pulleys handle one belt and suit low-power tasks, such as small fans or pumps. They are simple and inexpensive.

- Multi-groove V Belt Pulleys: Multi-groove types use multiple belts to increase power capacity. Each groove can add 10 to 20 horsepower. These are common in machinery that requires higher loads.

- Classical or Standard V Belt Pulleys: These pulleys have trapezoidal grooves that align with traditional V-belt. They are suitable for moderate horsepower applications and can operate efficiently even at higher rotational speeds.

- Narrow Profile V Belt Pulleys: These are designed for thinner, narrower belts and offer more precise speed control. They are often used in industrial tools such as drills and milling machines.

- Wide Profile V Belt Pulleys: Accommodating wider belts, these pulleys provide increased power capacity and are ideal for heavy-duty machinery with high torque requirements.

- Variable Speed V Belt Pulleys: Variable speed v-belt pulleys allow diameter adjustments by moving the sheave halves. This changes the speed ratio without replacing parts. They are suitable for equipment that needs adjustable output, such as blowers or lathes.

- Tapered Pulleys: Tapered pulleys use locking bushings for fast mounting and dismounting. This speeds up maintenance.

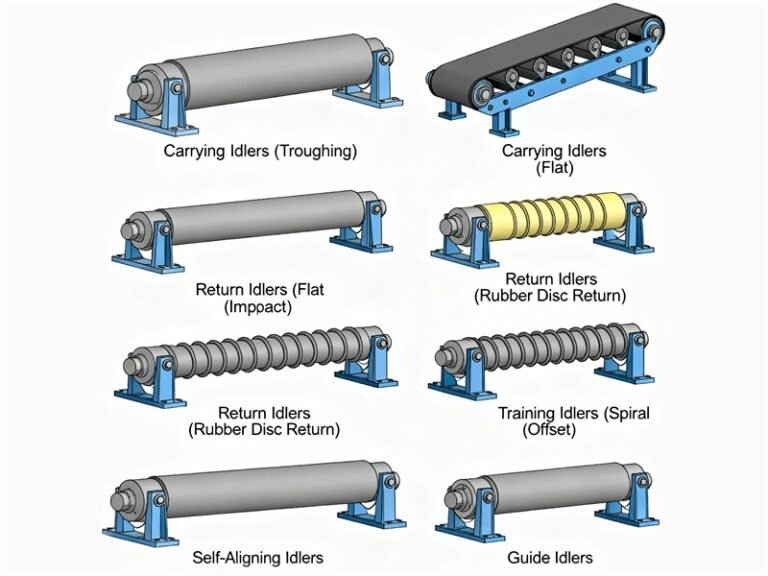

- Idler Pulleys: Idler pulleys maintain belt tension or change belt direction without transmitting power. They are necessary in multi-belt layouts.

- Step Pulleys: Step pulleys feature multiple diameters on one unit. Belts can shift between steps to alter speeds. This design appears in tools like drill presses.

- Custom V Belt Pulleys: Tailored to unique specifications, custom pulleys address particular operational challenges, such as unusual sizes, materials resistant to specific environments, or special mounting arrangements.

How to Choose the Right Custom V-Belt Pulley?

Choosing the right V-belt pulley often means customizing it to fit your application perfectly. At Jiangzhi, we design and manufacture custom V-belt pulleys based on your specific requirements, ensuring accurate fit, efficient transmission, and long service life.

Belt Compatibility: Every belt type requires a matching groove profile for proper grip and minimal wear. We customize groove shape, angle, and surface finish to suit your belt design and performance goals.

Material and Build: Different environments demand different materials. Whether you need lightweight aluminum, durable cast iron, or corrosion-resistant stainless steel, we tailor material selection and coating to match your working conditions.

Size and Speed: Pulley size determines belt speed and torque. With custom sizing, we fine-tune pulley diameters and ratios to achieve the ideal balance between power output and efficiency.

Load and Torque Requirements: For high-load or continuous-duty systems, our custom pulleys can include reinforced hubs, wider grooves, or special balancing to ensure strength, stability, and smooth performance.

Tailored Engineering: When standard pulleys do not fit your system, our engineering team develops custom-designed pulleys built to your exact specifications. This reduces downtime, enhances precision, and extends equipment life.

V Belt Pulley Applications

V-belt pulley systems find their way into myriad applications across industries, including:

Industrial Equipment: Conveyors, compressors, pumps, and fans.

Automotive: Engines, water pumps, and other auxiliary components.

Agriculture: Tractors and harvesters.

HVAC Systems: Fans and blowers.

Conclusion

V-belt pulleys deliver consistent power transfer. Selecting the right pulley for specific needs will optimize performance. Customization pulleys will solve specific issues. You are welcome to contact Flexiparts and get a custom solution.